Texas A&M’s New Metallic Gel Could Transform the Future of Liquid Metal Batteries

Researchers at Texas A&M University have created something the materials science world has never seen before: a metallic gel made entirely of metals that can hold its shape even at extremely high temperatures. This unusual material isn’t just a scientific novelty — it has the potential to reshape how liquid metal batteries (LMBs) are designed, built, and used, especially in places where batteries must withstand intense heat or movement.

This discovery came from the Materials Science and Engineering Department at Texas A&M, led by Dr. Michael J. Demkowicz and doctoral researcher Charles Borenstein. Their work, now published in Advanced Engineering Materials, shows how mixing metal powders and heating them in a controlled way can result in a semi-solid metallic structure that behaves like a gel while still containing a mostly liquid interior.

Below is a clear breakdown of what the research found, why it matters, additional background on LMBs, and what this could mean for future energy storage.

How the Metallic Gel Was Formed

The metallic gel originates from a surprisingly simple setup. The researchers mixed powders of two metals and heated them until one melted while the other remained solid.

- In their initial tests, they used copper (which melts) and tantalum (which stays solid at copper’s melting point).

- When heated, the copper became a liquid — but instead of pooling into a puddle, the tantalum formed a microscopic internal scaffold that held the copper in place.

- This created a material that looks solid but actually contains liquid metal trapped inside tiny metallic cavities.

- The most interesting part: this wasn’t expected at all. Normally, molten copper would simply flow out of the structure.

- When Borenstein tested different metal ratios, he found that any composition with more than 18% tantalum would maintain the gel-like form even when copper melted.

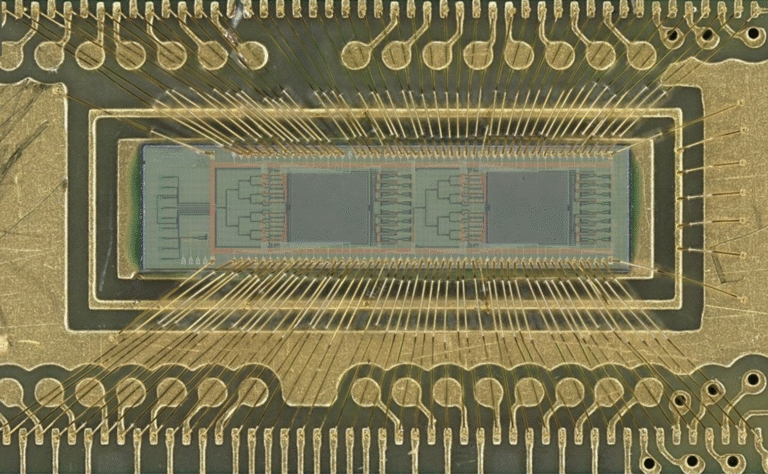

This wasn’t a one-off phenomenon, either. It was repeatable and structurally stable when viewed under a high-resolution micro-CT scanner, which revealed the tantalum skeleton supporting pockets of liquid copper.

The fact that the internal “gel” structure survives temperatures near 1,000 degrees Celsius makes this material dramatically different from everyday gels, which rely on organic backbones that only remain stable at room temperature.

Why Metallic Gels Matter for Liquid Metal Batteries

Liquid metal batteries are known for being capable of storing and releasing very large amounts of energy. Instead of using solid electrodes, LMBs use layers of liquid metals separated by a molten salt electrolyte. Because the metals self-segregate according to density, they naturally form layers.

But this design comes with a limitation:

- The layers shift when moved.

- Movement can mix the layers or cause physical contact between electrodes.

- This creates a risk of short circuits.

- Because of this, current LMBs are almost always stationary — used for things like backup power for buildings or grid storage.

This is where the metallic gel becomes a potential game changer.

A metallic gel electrode can contain liquid metal while still holding its shape. This means:

- The battery doesn’t rely solely on gravity for stability.

- Orientation changes are less dangerous.

- LMBs could eventually be used in moving systems.

That includes:

- Large ships

- Heavy-duty industrial vehicles

- High-temperature machinery

- Possibly even hypersonic vehicles, which operate in extremely hot environments where traditional batteries fail.

The Prototype Battery That Proved the Concept

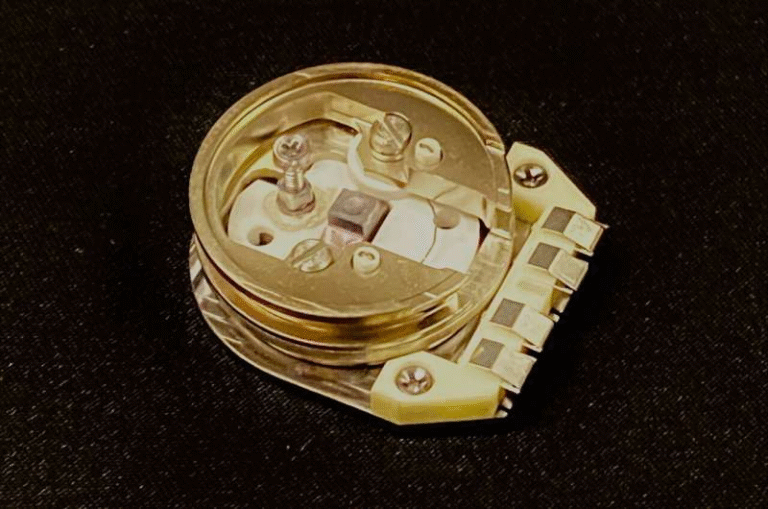

To test the real-world potential of the metallic gel, the researchers built their own small laboratory version of a liquid metal battery using gel-based electrodes.

Here’s how they designed the two cube-shaped electrodes:

- Anode: Liquid calcium trapped within a solid iron scaffold

- Cathode: Liquid bismuth trapped within iron

They immersed these electrodes in a molten salt electrolyte, which conducts ions between the two sides.

The result?

- The battery successfully produced electricity.

- The electrodes remained intact.

- The mostly liquid interior stayed where it needed to be.

This confirmed that liquid-containing metallic gels can function in a battery without collapsing or short-circuiting — a major milestone for the concept.

Where the Discovery Came From

Interestingly, the researchers weren’t trying to invent a metallic gel at all. They were initially exploring how copper–tantalum composites behave when heated, just to understand whether the structure remains intact when one metal melts.

Instead of collapsing, the composite kept its shape, revealing the unexpected gel-like behavior.

That unexpected result shifted the entire project toward applying the material to battery electrodes, where the combination of solid structure and liquid behavior could be uniquely useful.

Why This Could Matter for High-Temperature Technologies

Since metallic gels can withstand extreme heat, they open new possibilities for energy storage in environments that are too hot for typical lithium-ion batteries.

One especially interesting potential application is hypersonic vehicles — aircraft traveling faster than Mach 5, which generate enormous thermal loads.

A battery made of hot, stable metallic components could theoretically survive these temperatures without losing structural integrity.

LMBs powered by metallic gels could also be used in:

- High-temperature industrial processes

- Thermal energy storage systems

- Military aerospace technologies

- Remote power systems exposed to harsh environments

What Exactly Is a Liquid Metal Battery?

Here’s a bit of background to help readers understand the significance of the research.

Liquid metal batteries:

- Use liquid metals for both electrodes.

- Rely on molten salt as the electrolyte.

- Operate at very high temperatures (hundreds of degrees Celsius).

- Are resistant to mechanical wear because there are no solid materials to crack.

- Have very long lifespans.

- Can handle massive charge/discharge cycles suited for grid storage.

Their biggest limitation until now has been the danger of internal mixing, which the metallic gel concept directly addresses.

Challenges and Future Research Needs

As promising as this research is, several major questions remain:

- Can these metallic gels be produced consistently on large scales?

- How stable are they over thousands of battery cycles?

- How much would they cost using battery-friendly metals?

- Can mobility tests (vibration, acceleration, movement) prove long-term safety?

- What does a full-sized metallic-gel-powered LMB look like in real hardware?

Demkowicz’s team also mentioned the possibility of using a gel-like molten salt electrolyte, where a ceramic backbone holds the electrolyte in place similar to how the scaffold holds melted metal. This could lead to a fully gel-based LMB system with even greater stability.

A New Category of Materials

Beyond batteries, this discovery introduces an entirely new category of material: shape-preserving metallic gels.

Because they combine:

- metallic bonding,

- high conductivity,

- extreme-temperature tolerance,

- and liquid-phase flexibility,

they could eventually be used in areas such as:

- high-performance heat exchangers

- thermally adaptive structures

- shape-stable thermal storage materials

- advanced electronics that operate in extreme environments

The discovery also opens up many new scientific questions about how metals behave at micro-scales when one component melts and another doesn’t.

Research Reference

Shape-Preserving Metallic Gels with Applications as Electrodes for Liquid Metal Batteries

https://doi.org/10.1002/adem.202500738