AI-Guided Drones Are Learning to Build Structures in Places Humans Can’t Easily Reach

A new wave of research from Carnegie Mellon University is pushing aerial construction into territory that once felt impossible. Engineers from CMU’s College of Engineering have created a system where AI-guided drones can design and assemble structures using 3D-printing-inspired techniques—but instead of extruding material like traditional printers, these drones use magnetic building blocks and large language models (LLMs) to carry out precise construction tasks in hard-to-reach locations.

This development isn’t just a cool robotics experiment—it tackles the long-standing challenges of aerial manufacturing and opens the door to drones that might one day build emergency shelters, repair damaged infrastructure, or even help with off-planet construction.

Understanding the Core Idea Behind Aerial Additive Manufacturing

Aerial additive manufacturing (AAM) refers to construction performed by flying machines instead of ground-based robots or stationary 3D printers. It’s a fascinating idea, but the practical issues have always been obvious: drones are unstable, easily buffeted by air, and notoriously hard to control precisely. Traditional layer-by-layer 3D printing requires high precision, which drones simply can’t guarantee.

To sidestep this, the CMU team redesigned the entire process. Instead of forcing drones to extrude material accurately, they gave them custom magnetic blocks that snap into place and tolerate minor placement errors. This approach drastically reduces the precision drones need when building.

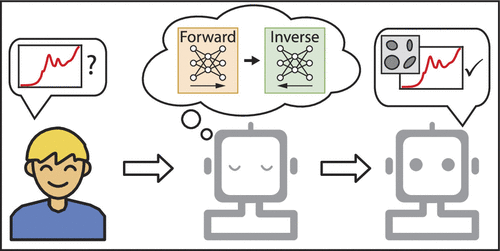

The second major innovation is their use of a large language model to act as a planner. Instead of pre-programming detailed construction instructions, the researchers can give the LLM a high-level command such as build a bridge, and the system translates it into actionable steps that the drone can execute.

The drone, the vision system, and the LLM form a loop that constantly checks progress, spots errors, and corrects the build plan without starting from scratch.

How the System Works From Start to Finish

1. Planning Through a Large Language Model

The LLM receives:

- a high-level design goal

- the current layout of blocks

- updates from the camera monitoring system

Then it generates a detailed plan that includes block positions, the order of placement, and backup strategies if something goes wrong. The plan is structured, often in JSON, so the drone can follow it step by step.

What makes the LLM particularly powerful is its ability to adapt in real time. If a block falls in the wrong place or a gap appears, the LLM recalculates the remaining steps and continues building instead of restarting. This adaptability is essential for aerial construction.

2. Vision System for Feedback

The drone’s actions are monitored using a camera setup capable of identifying:

- block placement accuracy

- grid alignment

- incorrect drops

- gaps in the structure

- overall build efficiency

The system can detect mistakes quickly and feed them back into the LLM so that the next instructions compensate for the error.

3. Mechanical Drone Capabilities

The team used drones equipped with grippers designed for magnetic blocks. These blocks connect through:

- magnetic snaps

- alignment ridges

- lightweight materials optimized for testing

This design ensures that even if a drone’s placement isn’t perfect, the block still connects properly.

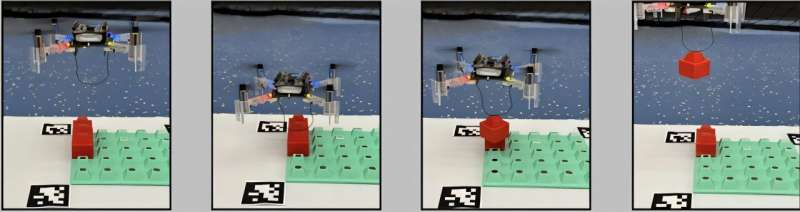

Performance in Lab Experiments

To evaluate the system, researchers created a 5×5 construction grid. The drone was given prompts to build specific shapes, including:

- a square

- a diamond

- a cross

- a smiley face

During these tests:

- If the drone misplaced a block, the vision system flagged it.

- The LLM then generated an adapted plan.

- The build continued from that point onward.

This closed-loop method led to a 90% success rate, showing that the system can reliably construct shapes despite inevitable aerial errors.

This demonstrates a major advantage of pairing LLM planning with drone actuation: instead of brittle, pre-programmed instructions, the build process remains flexible and resilient.

Why This Approach Matters

The combination of block-based construction and LLM planning makes aerial additive manufacturing much more feasible than previous attempts. Some key benefits include:

- Reduced precision requirements thanks to magnetic blocks

- Real-time error correction through LLM replanning

- Natural language-based design for high flexibility

- Adaptability for unpredictable environments

It’s not just about better performance—it’s about enabling construction in places people can’t easily reach.

Potential Real-World Uses

The researchers emphasize several future use cases:

1. Disaster Response

Imagine a region hit by an earthquake or flood. Roads may be blocked, and transporting heavy machinery becomes nearly impossible. Drones equipped with this technology could:

- build temporary shelters

- repair broken structures

- reconnect isolated areas with small bridges

2. Remote Infrastructure

In mountainous or heavily forested regions, traditional construction equipment struggles to reach build sites. Drones could handle tasks safely without needing access roads.

3. Space and Orbital Construction

The team talks about fixing spaceships or assembling structures in orbit—dream scenarios, but feasible in the long term once drones can operate in microgravity.

4. Urban Maintenance

Cities dealing with potholes, facade repairs, or structural fixes could deploy drones that operate in tight urban environments without blocking traffic.

Challenges That Still Need to Be Solved

Even with its promise, the system still has limitations:

- All tests occurred indoors under controlled conditions.

- Wind, weather, sunlight, and outdoor obstacles pose major issues.

- Drone stability remains a challenge, especially near surfaces where air turbulence intensifies.

- Magnetic blocks may not scale to heavy or load-bearing structures.

- Larger builds will require coordination between multiple drones, which introduces complexity.

- Outdoor localization without motion-capture systems is still a barrier.

The team plans to move testing outside the lab next, explore more complex structures, and use dynamic materials instead of predefined blocks.

The Broader Context of Aerial Robotics and Modular Construction

To give readers a bigger picture, here are a few facts and insights related to the field:

Aerial Robotics Is Growing Rapidly

Drones are becoming more capable thanks to:

- better sensors

- lighter materials

- more efficient motors

- powerful onboard processors

Areas like agriculture, surveillance, mapping, and delivery have already widely adopted drones. Construction is the next frontier.

Modular Construction is a Natural Fit for Robots

Modular systems—where structures are built from repeatable blocks—offer:

- higher speed

- easier automation

- reduced waste

- simpler logistics

Pairing modular blocks with drones combines two promising engineering paths.

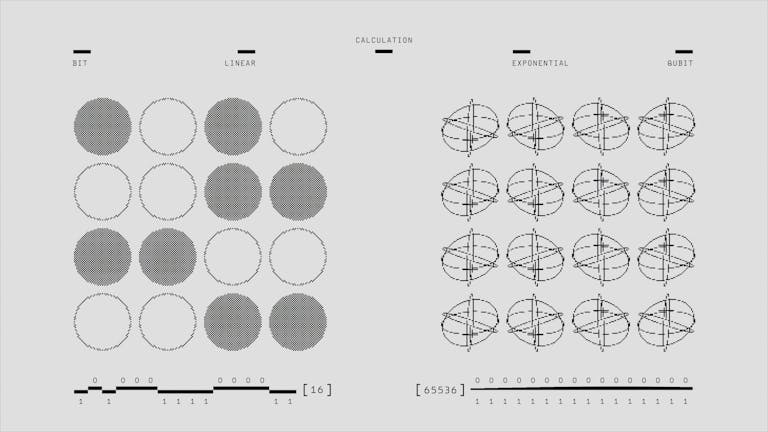

LLMs Are Becoming General-Purpose Planners

Beyond text generation, LLMs excel at:

- sequencing actions

- breaking down goals into tasks

- adapting strategies when environment changes

This research demonstrates that LLMs can serve as high-level supervisors for physical robots.

Future Multi-Drone Collaboration

Large structures would require swarms of drones working together using shared plans. This could eventually mirror biological swarm behaviors—ants building bridges or bees constructing hives—on a technological level.

Final Thoughts

The CMU research team’s work marks an exciting shift in how we think about construction. By merging drones, modular building blocks, camera-based feedback, and LLM planning, they have created a system with a 90% success rate in test scenarios that once felt impossible for aerial robotics. While it’s still early, this approach could reshape how we build in dangerous, remote, or unconventional environments.

Research Paper:

https://arxiv.org/pdf/2503.17566