Penn State Scientists Develop a High-Performance Lead-Free Ceramic That Can Harvest Energy From Everyday Vibrations

A team of materials scientists at Penn State has created an improved lead-free piezoelectric ceramic capable of turning everyday mechanical vibrations into usable electrical energy. This upgraded material is based on potassium sodium niobate (KNN) and is built to be lighter, thermally stable, fatigue resistant, and competitive with the widely used—but toxic—lead-based ceramics found in many energy-harvesting devices today.

This development is especially interesting because sources of vibration-based energy are all around us: footsteps on floors, gym machines, vehicle engines, construction equipment, bridges, and more. Devices made from piezoelectric materials convert these vibrations into electrical charges, offering a way to generate small but meaningful amounts of clean energy.

Below is a clear, detail-focused breakdown of what the Penn State team accomplished, how they did it, and why it matters.

Upgrading KNN: How the Material Was Improved

KNN has long been considered one of the most promising lead-free alternatives to conventional piezoelectrics. But to make it compete with established materials, the Penn State researchers had to improve both its structure and its chemistry.

They began by adding manganese, a magnetic element, to the ceramic composition. This helped boost its electrical properties and improve performance stability.

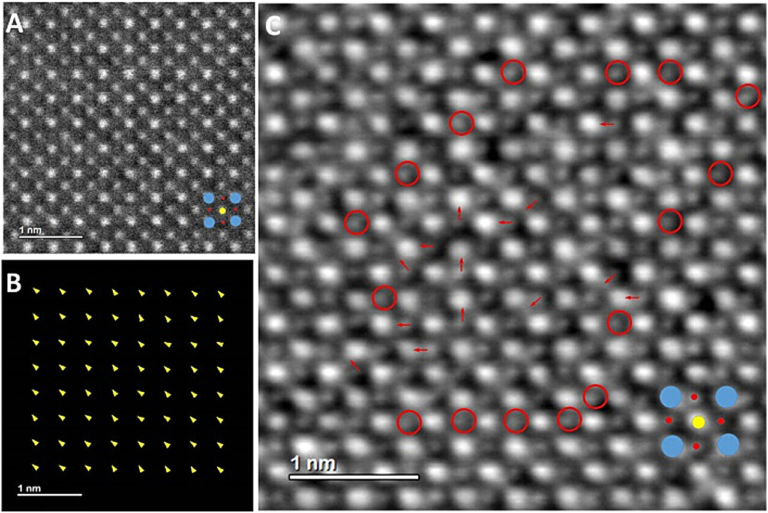

Then, they focused on grain growth within the ceramic. Every ceramic is made up of countless microscopic crystals (grains). Normally, these grains grow in random directions, limiting mechanical strength and piezoelectric performance. The researchers used carefully tuned heat treatments and fabrication methods to control grain direction so that the grains grew in alignment, not randomly. Achieving this unidirectional grain growth increased the material’s mechanical strength, toughness, and piezoelectric response.

Because ceramics are inherently brittle, the team also kept real-world application challenges in mind. This grain-aligned structure is especially helpful for devices like cantilevers—components that flex repeatedly in response to vibrations.

How Energy Harvesters Work

Most vibration-harvesting devices use a cantilever design:

- One end is fixed,

- The other is free to move.

When mechanical force is applied—like a step on a floor—the cantilever bends and vibrates. The piezoelectric ceramic inside converts that mechanical motion into an electrical charge.

The Penn State team’s redesigned KNN ceramic performed just as well as conventional lead-based materials in energy-harvesting tests. This is a big deal, because breaking away from lead without losing efficiency has been a major challenge in this field.

Why the Lighter Weight Matters

Traditional piezoelectric materials use lead, giving them higher density. The upgraded KNN ceramic, however, is significantly lighter, opening doors to applications where weight matters—especially aircraft.

The researchers suggest that piezoelectric harvesters made from this material could be integrated into airplane structures to capture vibrations encountered at high altitudes. Lead-based materials cannot be used safely or effectively in this context, so this new ceramic could unlock entirely new use cases.

Performance Compared to Lead-Based Materials

The researchers directly compared their improved KNN ceramic to standard lead-based ceramics widely used in industry. In laboratory vibration tests, the upgraded KNN showed similar levels of energy output, meaning its power-generation capability finally matches what lead-based materials have provided for years.

This makes it the first lead-free piezoelectric ceramic that actually performs on par with established lead-containing alternatives.

Potential Applications

The improved KNN ceramic could be used in a range of energy-harvesting and sensing applications:

Everyday Vibration Harvesting

- Dance floors

- Hallways and corridors

- Bridges and parking decks

- Sidewalks and public walkways

- Workout machines

With enough harvesters embedded, these environments could produce electricity to power sensors, small lights, or batteries.

Aircraft and Transportation

Because of the reduced density, the ceramic could be embedded in:

- Aircraft wings or fuselage panels

- Vehicle frames

- Train components

These structures naturally vibrate, giving constant opportunities to generate power.

Sensor Technology

Piezoelectric materials are also widely used in sensors. Potential sensor types include:

- Weight sensors

- Sound and ultrasonic sensors

- Position and motion sensors

- Air pressure and environmental sensors

- Optical/light-responsive sensors

Biomedical Devices

Since the ceramic is lead-free and biocompatible, it could be safely used inside the human body. The team highlights possible applications such as:

- Self-powered pacemakers

- Neural stimulation devices

- Wearable medical sensors

These devices could harvest the body’s natural vibrations—heartbeat, movement, or muscle motion—to run themselves without needing frequent battery changes.

Why Lead-Free Ceramics Are So Important

Most commercial piezoelectric ceramics contain lead, which presents several issues:

- Environmental toxicity

- Complicated disposal and recycling

- Restrictions under regulations like RoHS

- Unsuitability for biomedical implants

Developing strong lead-free alternatives has been a priority for decades. While KNN has long been promising, it has always fallen short—until now.

The Penn State breakthrough suggests that, with the right combination of microstructural engineering, chemical tuning, and precise grain control, lead-free piezoelectrics can finally become practical replacements.

Understanding Grain Alignment in Simple Terms

To understand why grain alignment matters, imagine trying to push several objects in the same direction. If they’re aligned, you can push them efficiently. If they’re all facing random directions, your push achieves much less overall movement.

Piezoelectric ceramics work similarly. When grains are aligned:

- More of the input energy becomes electrical energy

- Mechanical strength improves

- Fatigue resistance increases

- The device can handle more repeated stress

That’s why unidirectional grain growth is such a major achievement in the new ceramic design.

Broader Impact on Energy-Harvesting Technology

Energy harvesting from mechanical vibrations is becoming more attractive because:

- It supports self-powered IoT devices

- It can reduce battery waste

- It can power sensors in remote or inaccessible locations

- It helps create smart infrastructure

- It enables greener technology in consumer electronics

This research pushes the field forward significantly by providing a viable lead-free material that can be scaled into practical devices.

The next phase for the Penn State team includes:

- Testing the material in real-world environments

- Designing complete energy-harvesting devices

- Exploring integration with wearable technologies

- Studying its long-term durability under daily mechanical stress

Given how broad the potential applications are, this upgraded KNN ceramic could play a key role in future smart cities, transportation systems, and biomedical technologies.

Research Reference

Textured Lead-Free Ceramic With High Thermal Stability and Electrical Quality Factor

Link: https://onlinelibrary.wiley.com/doi/10.1002/smll.202505193