Harvard Researchers Develop Wearable Textile That Can Dynamically Change Its Aerodynamics

A team of engineers at the Harvard John A. Paulson School of Engineering and Applied Sciences has created a novel textile capable of adjusting its aerodynamic properties on demand. This new fabric, described in a recent study published in Advanced Materials, uses dimpling patterns similar to those found on golf balls to reduce drag and improve performance in situations involving high-speed airflow. The research brings together expertise in fluid dynamics, metamaterials, and wearable technology, offering a new direction for sports apparel and potentially influencing industries like aerospace, maritime engineering, and civil design.

This work comes from the combined efforts of two Harvard laboratories: the group led by Katia Bertoldi, a well-known figure in the field of metamaterials, and the group led by Conor J. Walsh, a prominent researcher in engineering and wearable systems. The project itself was spearheaded by David Farrell, a mechanical engineering graduate student whose interests lie in the intersection of fluid mechanics and engineered materials.

How the Textile Works

The key idea behind the textile is its ability to form surface dimples when it is stretched. Unlike typical fabrics that simply tighten and smooth out under tension, this material is deliberately designed to deform in the opposite way. Instead of flattening, it creates controlled indentations across its surface.

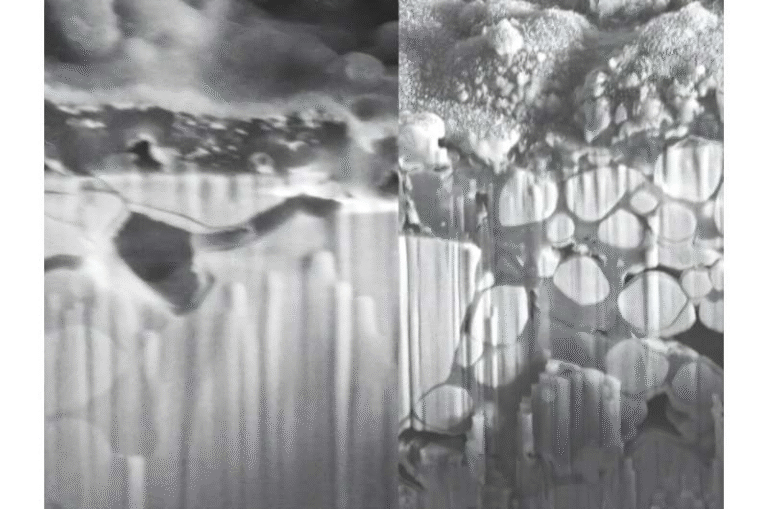

This dimpling effect is achieved by bonding two different layers together:

- A stiffer black woven material, similar in texture to the straps on a backpack

- A soft, flexible gray knit that provides stretch and comfort

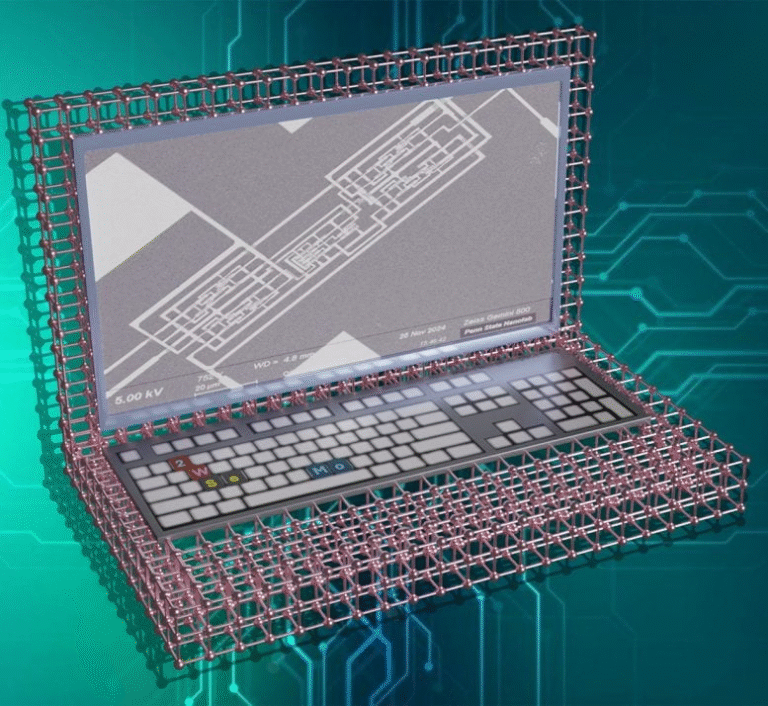

These two layers are cut and bonded through a two-step process involving a laser cutter and a heat press. The team experimented with multiple lattice geometries, such as squares, hexagons, and hourglass patterns, to understand how different shapes affect the fabric’s response when stretched.

The resulting composite forms dimples automatically when a person wearing it moves or when the material experiences tension. Because these dimples influence airflow, the fabric effectively tunes its aerodynamic performance in real time.

Why Dimples Matter: The Golf Ball Principle

The benefit of a dimpled surface is well established in aerodynamics. Golf balls, for example, are intentionally covered with dimples because these small indentations create turbulence in the layer of air surrounding the ball. This turbulence reduces aerodynamic drag and allows the ball to travel farther.

The Harvard team applied the same principle to fabric. By adjusting the size and shape of dimples through stretching, the material can be optimized for different wind-speed ranges. The researchers performed 3,000 computer simulations to test variations in dimple geometry and then verified the most promising patterns through wind tunnel testing.

Some configurations were shown to reduce drag by up to 20%, which is a significant performance improvement for sports where fractions of a second matter.

What Makes This Textile Different

Traditional sportswear fabrics are designed to fit snugly, compress muscle, or regulate moisture. However, their aerodynamic properties are fixed at the time of manufacturing. They don’t dynamically change based on motion or airflow.

This new textile does something completely different. Thanks to its lattice-patterned structure, it expands when stretched around the body, rather than tightening. This expansion causes the surface to buckle into dimples instead of smoothing out, reversing the normal behavior of clothing. This behavior is rooted in metamaterial science, an area where structures derive their unique properties not from the materials themselves but from their engineered geometry.

The underlying lattice design is based on work that Bertoldi and others have explored for nearly a decade. The idea is to use geometric patterns that induce mechanical responses not seen in standard textiles. Applying this concept to wearable technology represents a major step toward creating adaptive clothing that responds directly to the environment.

Potential Applications Beyond Sports

While the most obvious use case is high-speed athletics—such as road cycling, downhill skiing, or speed skating—the potential applications extend far beyond sportswear.

Aerospace Surfaces

Aircraft and drone components could benefit from surfaces that adjust roughness depending on speed or direction of airflow, which could lead to improved fuel efficiency or maneuverability.

Maritime Engineering

Boat hulls or underwater vehicles could incorporate such materials to reduce drag in water, a medium where small reductions in resistance can translate to large energy savings.

Civil Engineering

Architectural structures might use similar adaptive surfaces to control wind load on buildings or bridges, particularly in areas prone to strong winds.

Wearable Technology

Future “smart fabrics” could integrate this idea with sensors or actuators to create clothing that autonomously adapts to motion, speed, temperature, or environment.

How the Research Was Conducted

The team began by designing a library of patterns using finite element simulations, exploring thousands of dimpling configurations. After identifying the most promising candidates, they created physical samples using laser-cut woven sheets bonded to stretchable knit layers.

These samples were then placed in a wind tunnel, where the researchers measured drag forces at different velocities and different states of stretch. They found that the optimal pattern changed depending on wind speed, demonstrating that a single textile design could adapt its surface properties for multiple conditions.

Importantly, the fabric continued to produce dimples even when wrapped around curved parts of the human body. This is a nontrivial achievement, since most metamaterial research occurs on flat samples that don’t behave the same way once wrapped or draped.

Broader Context: Metamaterials in Everyday Use

This textile is part of a broader shift in material science where structural design, rather than chemical composition, defines performance. Metamaterials have been used to create programmable mechanical responses, acoustic cloaking, impact-resistant structures, and soft robotics components.

Applying these concepts to clothing is relatively new but rapidly gaining interest. Wearable metamaterials can potentially offer:

- On-demand stiffness changes

- Improved breathability and comfort

- Better airflow control

- Impact or vibration absorption

- Shape-changing garments

This study demonstrates how metamaterial ideas can transition from theoretical mechanics to real-world, flexible, and usable products.

What Comes Next

The researchers indicate that the textile is still in an early stage. Scaling up from flat test samples to full garments will require additional work. Questions remain regarding durability, repeat stretching cycles, breathability, and manufacturing cost.

However, the potential impact is clear. Adaptive aerodynamic clothing could redefine performance standards in professional sports and open the door to new engineering solutions where controlling fluid flow is critical.

The Harvard Office of Technology Development is already involved in protecting and exploring commercialization of the technology, suggesting that real-world products based on this research may not be far off.

Research Reference:

Programmable Surface Dimpling of Textile Metamaterials for Aerodynamic Control – Advanced Materials (2025)