Silicon Carbide Motor Drive Makes Hybrid Electric Aircraft Smaller, Lighter, and More Efficient

A team from the University of Arkansas has successfully demonstrated a major step forward in hybrid-electric aviation: a silicon carbide-based motor drive that makes aircraft propulsion systems significantly smaller, lighter, and more efficient than traditional silicon-based designs. This achievement was validated through a real-world flight test on a hybrid Cessna 337 in Southern California in 2023. The work has now been published in IEEE Transactions on Power Electronics, and it highlights why silicon carbide technology is quickly becoming one of the most promising foundations for next-generation electric transportation.

How the Test Flight Was Conducted

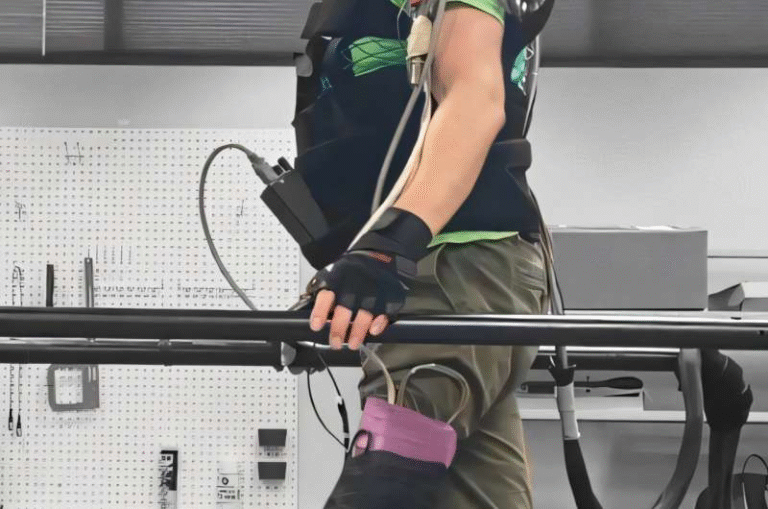

The aircraft used for the project was a hybrid Cessna 337—an airplane commonly used for short-range commuter routes, including air taxi services over island chains. In this particular setup, the plane retained its gasoline-powered engine in the nose, while the rear electric motor was outfitted with the University of Arkansas team’s new silicon carbide inverter.

The inverter is the heart of an electric propulsion system. It converts DC power from the battery into AC power that drives the electric motor. Traditional systems rely on silicon-based transistors, but the UA Power Group replaced those with silicon carbide (SiC) components and redesigned the drive accordingly.

During the test flight, the plane taxied, accelerated, and lifted off smoothly, validating that the experimental SiC drive could withstand the mechanical stress, altitude conditions, and electrical demands of real aviation—not just laboratory conditions. This was a notable achievement because university-developed power electronics rarely reach the flight-test stage.

Why Silicon Carbide Matters

The appeal of silicon carbide lies in how dramatically it outperforms silicon in high-power environments. Transistors made from silicon carbide can switch up to 1,000 times faster than their silicon counterparts. This faster switching speed directly improves efficiency and reduces energy lost as heat.

Because of this efficiency boost, every supporting component—inductors, capacitors, transformers, and cooling hardware—can be smaller and lighter. In aviation, this matters enormously. When every kilogram affects range, payload, and power demands, a lighter motor drive is more than just convenient—it directly strengthens performance.

The team emphasizes that a SiC-based system can shrink the motor drive from something bulky and heavy to something compact enough to fit in your hand while delivering the same power output. For aircraft designers, that’s a transformative shift.

Weight and Space Savings for Aircraft

In a small aircraft, every inch of space counts. A conventional inverter takes up significant room, forcing compromises in cabin design, cargo space, or battery configuration. But a SiC-based system slashes the required footprint so much that designers could realistically rethink cabin layouts or simply provide more legroom for passengers.

The weight reduction also lowers energy demand during takeoff and cruising, where power loads are highest. That directly feeds into better efficiency, potentially longer ranges, and more economically viable hybrid-electric aircraft.

The Challenges of Using SiC in Aviation

Aviation is an unforgiving environment. It introduces several unique complications for any electrical system:

Mechanical Stress

Aircraft vibrate constantly, and impact forces during landing can rattle electronics apart if they’re not carefully designed. The University of Arkansas team engineered the inverter’s structure and supports to survive this environment.

Partial Discharge at High Altitude

At altitude, the air is thinner and drier. This increases partial discharge, an electrical phenomenon that can degrade insulation and cause failure over time. The researchers had to account for this in insulation design and materials selection.

Electromagnetic Interference

The extremely fast switching speeds of silicon carbide create more electromagnetic interference (EMI) than slower silicon devices. Aircraft are full of sensitive instruments and control systems, so EMI issues can be serious safety concerns. The team implemented multiple layers of EMI mitigation to ensure safe operation.

Overcoming these challenges and proving reliability in flight is what makes this test a noteworthy milestone.

Why Silicon Carbide Isn’t Everywhere Yet

Despite its advantages, silicon carbide has historically been limited by cost. Pure silicon is incredibly cheap because it’s refined from sand, while silicon carbide requires more complex and expensive fabrication processes.

However, costs are falling quickly as production techniques improve. Companies in the automotive sector—Ford, Toyota, and others—are increasingly adopting SiC components in electric vehicles. As demand grows and economies of scale kick in, the overall system cost shrinks too.

This means that although the transistor materials themselves may still cost more, the entire system can become cheaper because it needs fewer and smaller supporting components. Silicon carbide also demonstrates superior efficiency and durability, further improving lifetime cost.

Manufacturing Limitations

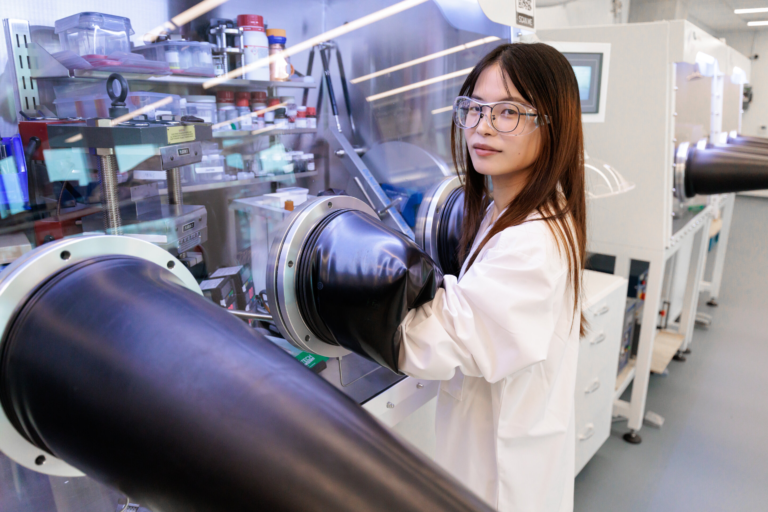

It’s worth noting that current SiC production processes aren’t yet advanced enough to fabricate nanometer-scale chips, the kind needed for cutting-edge computer processors. But power electronics, like those used in electric drivetrains, do not require such tiny geometries. To help bridge the gap between research and manufacturing, the University of Arkansas will soon open a new Multi-User Silicon Carbide Research and Fabrication Laboratory dedicated to SiC microchip development.

Benefits for Students and the Broader Engineering Community

One aspect the researchers highlighted is the educational impact. Students involved in the project gained direct experience with real-world aircraft integration, testing, and engineering problem-solving. That experience has already helped many of them secure excellent jobs in the power electronics and aerospace industries.

For the broader engineering community, this project provides a valuable case study showing that silicon carbide-based systems can operate reliably under flight conditions. It sets a precedent for future hybrid-electric or fully electric aircraft projects across academia and industry.

What This Means for the Future of Hybrid-Electric Aviation

Hybrid-electric propulsion is one of the most promising paths toward lower-emission aviation, especially for short-haul routes where full battery-electric flight is still limited by energy density. A lighter and more efficient motor drive directly supports these goals.

As SiC technology becomes more mature and cost-effective, we can expect stronger adoption not only in experimental aircraft but also in commercial electric aviation, including regional aircraft, air taxis, and cargo drones.

This flight test demonstrates that silicon carbide is not merely a theoretical improvement—it is a practical and immediately beneficial technology that can improve the performance and feasibility of electric propulsion today.

Additional Background: What Makes Silicon Carbide So Efficient?

Although the news focuses on the aircraft test, it’s useful to understand why silicon carbide is such an important material in modern power electronics.

Higher Breakdown Voltage

SiC can handle higher voltages without breaking down. This makes it ideal for high-power environments like cars, aircraft, and industrial power systems.

Better Thermal Conductivity

SiC dissipates heat much more effectively than silicon. This reduces the need for bulky cooling systems.

Higher Switching Frequencies

Because it switches faster with less energy loss, SiC enables:

- Smaller inductors

- Smaller capacitors

- Smaller transformers

- Reduced heat sinks

- Higher efficiency

This results in power converters that are more compact yet deliver the same or better performance.

Common Uses Today

Silicon carbide is already used in:

- Electric vehicle inverters

- Renewable energy power converters

- High-power industrial drives

- Data center power supplies

- Train and rail systems

Aviation is simply the next frontier.

Final Thoughts

The University of Arkansas team has demonstrated that silicon carbide power electronics can be flight-ready, and the successful test flight of their hybrid Cessna 337 marks a major step for electric aviation. By shrinking the size and weight of critical propulsion components, SiC technology could play a central role in making hybrid-electric and eventually fully-electric aircraft more practical, efficient, and commercially viable.

Research Paper:

Development, Integration, and Flight Testing of a Silicon Carbide Propulsion Drive for a Hybrid Electric Aerospace Application

https://doi.org/10.1109/tpel.2025.3597905