Penn State’s New All-Climate Battery Design Promises Stable Performance From Freezing Cold to Desert Heat

Researchers at Pennsylvania State University have introduced a new all-climate battery (ACB) design that aims to eliminate one of the biggest weaknesses of today’s lithium-ion batteries: their inability to perform consistently across extreme temperatures. This new approach combines optimized high-temperature materials with a built-in internal heating system, allowing the battery to stay efficient, safe, and stable whether it’s operating in harsh winter cold or intense summer heat. The concept is straightforward but ambitious—create a lithium-ion battery that works reliably from –50°C to 75°C, far beyond the normal operating window of today’s systems.

Why Lithium-Ion Batteries Struggle With Temperature Extremes

Lithium-ion batteries have become the backbone of modern energy storage, powering everything from smartphones to electric vehicles (EVs), drones, and massive data centers. But they weren’t originally designed for the broad range of environments and power-intensive applications they’re used in today. Their ideal operating temperature has always hovered around 25°C, a comfortable room-temperature range that’s rarely maintained in real-world conditions without help.

At low temperatures, lithium-ion batteries lose power because the chemical reactions inside them slow significantly. At high temperatures, the liquid electrolytes inside can become volatile, which increases the risk of reduced longevity or even dangerous failures. To compensate, manufacturers rely on bulky external heating and cooling systems—an approach that adds weight, complexity, energy consumption, and cost.

Even with these external systems, conventional lithium-ion batteries typically operate dependably only between –30°C and 45°C. That still restricts their usefulness in scenarios like satellites, high-altitude drones, polar regions, or solar installations in extremely hot climates.

What Makes the All-Climate Battery Different

The Penn State team’s breakthrough comes from using two complementary strategies instead of focusing on just one. The new ACB design includes:

- Optimized materials in the electrodes and electrolytes that can tolerate sustained high-temperature operation without becoming unstable.

- An internal heating structure, powered directly by the battery, that warms the cell during cold conditions to ensure strong low-temperature performance.

By combining these two elements, the battery avoids the typical trade-off: improving one temperature extreme at the cost of worsening the other. This synergy is a key point in the research.

A Closer Look at the Internal Heating System

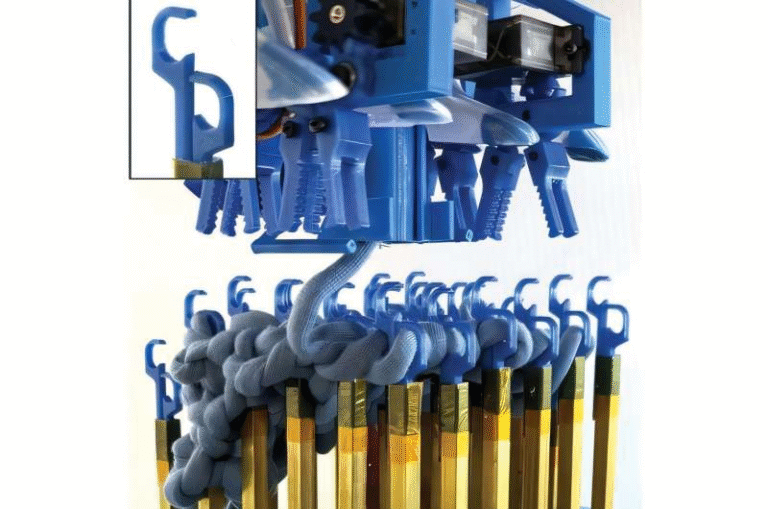

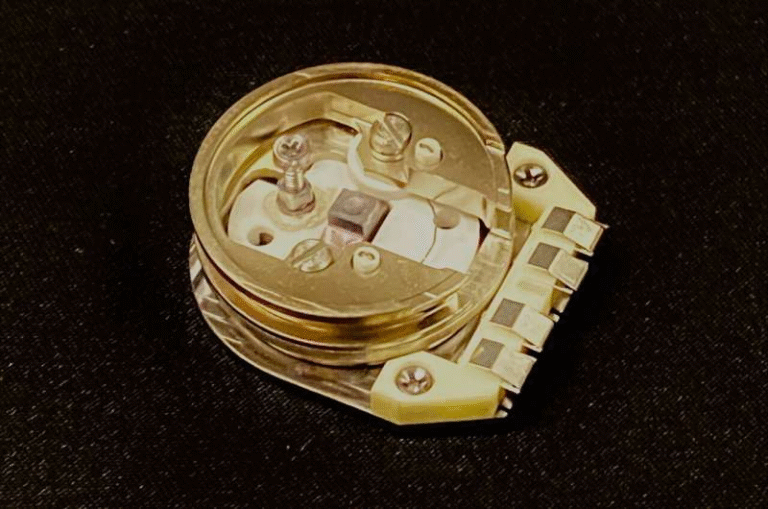

The heating system inside the proposed ACB uses a thin layer of nickel foil, about 10 microns thick, similar in width to a red blood cell. This metallic layer acts as a lightweight internal heater that warms the battery quickly and efficiently when ambient temperatures drop. Because the heater is embedded inside the battery and powered by the battery itself, it doesn’t add any significant bulk or energy overhead. It also enables the battery to regulate its own temperature without requiring energy-hungry external systems.

According to the team, this simple internal addition unlocks the ability to fine-tune the rest of the battery specifically for high-temperature stability. Materials can now be selected primarily for safety, low volatility, and durability at high heat, since the internal heater will take care of low-temperature challenges.

Material Optimizations for High-Temperature Stability

A large part of the battery’s improvement comes from upgrading the traditional components—particularly the liquid electrolyte, which tends to be the weak point in high-heat environments. Standard lithium-ion electrolytes are flammable and degrade quickly at higher temperatures. The ACB design replaces or reformulates these electrolytes and adjusts electrode materials so they perform safely even in hot environments such as:

- Enclosed EV battery packs

- Data centers with dense heat-generating equipment

- Industrial energy-storage systems exposed to extreme conditions

- Solar farms located in high-temperature regions

By targeting heat stability first, and allowing the internal heating film to address cold performance, the researchers can extend the battery’s operating envelope far beyond what conventional designs allow.

Expanded Temperature Range and Performance Benefits

The proposed ACB design increases the battery’s usable external temperature range to –50°C all the way up to 75°C. With continued development, the team also believes this upper limit could eventually push toward 85°C. That’s a significant jump and opens the door for deployment in conditions previously considered too dangerous or unreliable for lithium-ion storage.

Another benefit is the removal—or substantial reduction—of external thermal-management systems. Eliminating these reduces:

- Weight and space requirements inside EV battery packs or thermal enclosures

- Power consumption, since onboard heaters and coolers won’t need to run

- Maintenance costs, especially in large facilities like data centers

- System complexity, which contributes to both cost and long-term reliability

These simplifications could translate into meaningful savings, particularly in industrial applications where thousands of batteries operate around the clock.

Where This Technology Could Have the Biggest Impact

The wider temperature capability directly benefits industries that need dependable storage in extreme climates or demanding environments. Some examples include:

- Electric Vehicles (EVs): More reliable cold-weather startup, better thermal stability under heavy load, and potentially longer lifespan.

- Remote Renewable-Energy Storage: Solar farms in deserts or Arctic research stations need batteries that tolerate environmental extremes without constant climate conditioning.

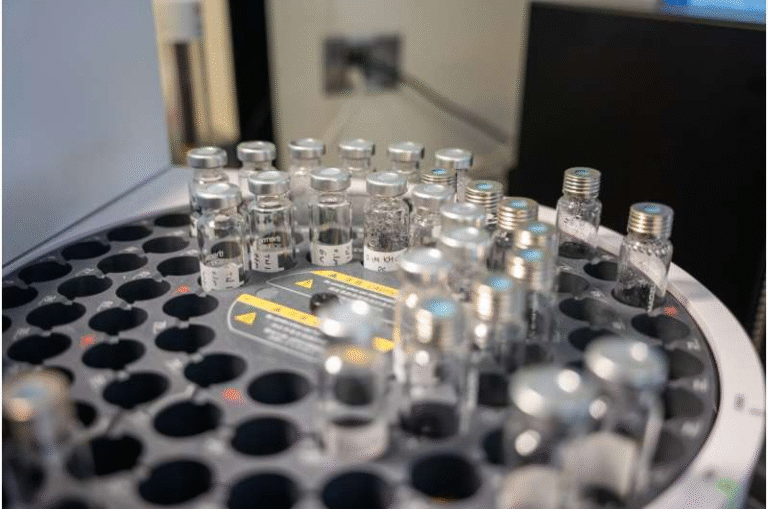

- Data Centers: As artificial-intelligence computation grows, data centers require stable power backup systems, often in high-heat environments. Removing external cooling simplifies these setups.

- High-Altitude or Harsh-Environment Drones: These rely heavily on batteries that perform consistently despite extreme cold or significant temperature cycling.

- Space Applications: Satellites and near-space systems face high thermal variability, making a stabilizing battery design valuable.

Broader Context: Why Battery Innovations Like This Matter

Our society continues to move toward electrification across almost every sector. EV ownership is rising. AI data centers are becoming energy-hungry giants. Renewable energy capacity is expanding. And drones, robotics, and advanced electronics are becoming more specialized and widespread.

All of these depend on stable, predictable, and safe energy storage. Thermal issues are one of the biggest obstacles preventing lithium-ion batteries from scaling even further. A battery that can reliably withstand a much wider range of temperatures isn’t just a convenience—it helps pave the way for new kinds of devices, harsher deployments, larger energy infrastructures, and improved safety.

What Comes Next

The Penn State team plans to further develop, test, and deploy their ACB design. While optimistic, they acknowledge that additional engineering and validation will be required before commercial adoption. Real-world cycle life, mass-manufacturing feasibility, long-term durability, and cost considerations are still open questions. But the concept is strong, and the early results show real promise.

If successful, this research could reshape the way the battery industry approaches thermal management, shifting emphasis from bulky external systems to smarter, integrated internal solutions.

Research Paper

All-Climate Battery Energy Storage (2025) – Joule

https://www.cell.com/joule/fulltext/S2542-4351%2825%2900359-9