AI Breakthrough Maps Alloy Microstructures to Transform Materials Design and Property Prediction

Researchers at the University of Illinois Urbana-Champaign have developed a new AI-powered method that could dramatically speed up how we discover, test, and design advanced metal alloys. This approach, created by the team led by materials scientist Jean-Charles Stinville, focuses on capturing the complete microstructural “fingerprint” of alloys—something traditional methods could never fully achieve.

Their goal is simple but ambitious: enable faster and more accurate predictions of mechanical properties such as strength, fatigue life, and ductility, while paving the way for intelligent, even autonomous alloy design.

Below is a straightforward, detail-rich breakdown of the work, along with additional context that helps explain why this research matters.

Understanding Why Alloy Microstructures Matter

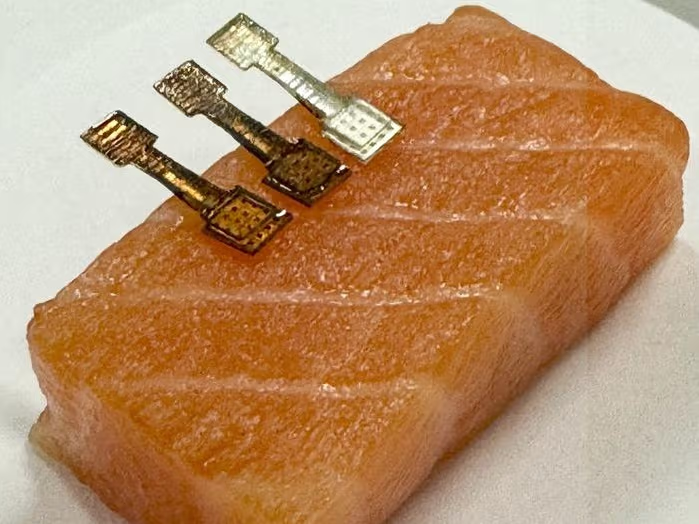

Every alloy—whether used in spacecraft, jet engines, or structural components—has a microstructure made up of grains, boundaries, and tiny defects. These microstructures directly determine how the metal behaves when it’s pushed to extremes.

Modern alloys used in rockets and airplanes, for example, must endure extreme temperatures, intense mechanical loading, and highly variable environments. Even slight variations in microstructure can dramatically change how long a metal lasts or how it fails.

However, traditional characterization techniques reduce the complexity of microstructures into average values or a few descriptors, essentially flattening a rich fingerprint into a handful of numbers. This makes alloys look more similar than they really are and limits our ability to predict their behavior precisely.

Stinville’s team set out to change this.

Capturing the Full “Fingerprint” of Metals With AI

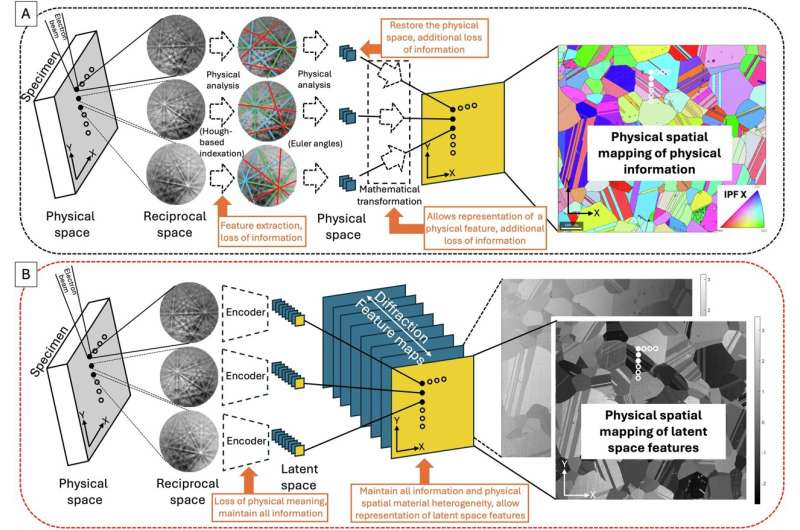

Instead of compressing microstructures into simplified metrics, the researchers used deep learning to analyze raw diffraction patterns—the patterns created when electrons interact with the metal’s internal structure.

These diffraction patterns, including detailed Kikuchi patterns, contain a massive amount of information about local crystal orientation, defects, heterogeneities, and other structural features. Extracting all of that manually is impossible.

Using AI, the team encoded these complex interactions into a spatial latent representation, a form of compressed but information-rich data that preserves all critical details across a large field of view. Stinville has termed this approach Material Spatial Intelligence.

This allows the AI to:

- Map spatial variations and heterogeneities with unprecedented accuracy

- Capture microstructural features that typical descriptors overlook

- Build a representation of the alloy that is both comprehensive and computationally manageable

The researchers published this initial model in npj Computational Materials, where it successfully identified microstructure heterogeneity in greater detail than previous methods ever achieved.

From Microstructure Mapping to Predicting Material Behavior

In a second study published in Scripta Materialia, Stinville advanced this approach to predict mechanical properties based on the detailed microstructural maps. Traditionally, testing these properties requires extensive mechanical experiments, which take time, specialized equipment, and sometimes destructive testing.

Using high-resolution digital image correlation combined with the AI-generated microstructure maps, the research team trained a model to recognize microscopic deformation patterns—essentially, the way tiny regions of metal stretch, bend, or distort when loaded.

This allowed them to develop a predictive system that estimates:

- Strength

- Fatigue life (how long a metal lasts before cracking)

- Ductility (how much it can stretch before breaking)

The key benefit: these predictions are made orders of magnitude faster than traditional testing and with strong reliability.

The implications for materials engineering are enormous. Faster property prediction means faster design cycles, reduced cost, and the ability to explore many more alloy compositions in a short time.

Why This Approach Represents a Major Shift

Stinville’s method avoids the usual pitfall in materials informatics: relying too heavily on averages or hand-crafted descriptors. Instead, it integrates:

- Experimental insight (capturing high-resolution fields of view)

- Physics (understanding how metals deform and why)

- Data science (encoding spatial information through machine learning)

This creates a hybrid approach combining the strength of classical metallurgy with the power of modern AI.

The spatially rich data opens the door to much more accurate models. Because heterogeneities often govern failure, capturing them is essential for predicting performance under extreme conditions—such as outer space, high-speed flight, or turbine environments.

Towards Fully Autonomous Alloy Design

Stinville’s long-term vision is a system that works backwards from user requirements.

You could input:

“I need an alloy that can withstand X temperature, Y loading, and Z fatigue cycles.”

The system would then propose:

- A chemical composition

- A target microstructure

- Processing steps necessary to achieve it

This would mark a major departure from today’s trial-and-error methods and could lead to a new era of AI-driven materials discovery.

His lab is already moving toward this goal by integrating automated characterization with Material Spatial Intelligence, suggesting that fully autonomous alloy design might soon become a reality.

Additional Background: What Are Diffraction Patterns and Why Are They Important?

Since this research relies heavily on diffraction-based mapping, here’s some context.

What Are Kikuchi Patterns?

These are fine electron diffraction patterns captured during techniques like EBSD (Electron Backscatter Diffraction). They reveal:

- Crystallographic orientation

- Lattice distortions

- Sub-grain features

- Local defects

Each pattern is like a tiny snapshot of the atomic structure at a specific point.

Traditionally, only parts of these patterns are turned into descriptors. The new AI model, however, utilizes the entire pattern, ensuring nothing is lost.

What Are Microstructural Heterogeneities?

Heterogeneities are the small but significant differences across an alloy’s microstructure. These include:

- Variations in grain shape and size

- Localized dislocation densities

- Micro-precipitates

- Sub-grain structures

- Residual strain pockets

These small differences often dictate where cracks form or how a metal responds under stress. Mapping them accurately is crucial for reliable property prediction.

Why AI Is Transforming Materials Science

As materials become more advanced, their microstructures grow more complex—especially with technologies like additive manufacturing, which can introduce layered, directional, and hierarchical structures.

Traditional characterization is too slow or too limited to deal with this complexity. AI allows researchers to:

- Analyze massive datasets quickly

- Capture subtle features that humans miss

- Build models that learn from real examples rather than predefined rules

- Improve predictions as more data becomes available

The method developed by Stinville’s lab is part of a broader movement pushing materials science into a data-rich, AI-enhanced future.

Reference to the Research

Learning metal microstructural heterogeneity through spatial mapping of diffraction latent space features

https://www.nature.com/articles/s41524-025-01770-8