Oregon State Researchers Create a Fast-Curing, Eco-Friendly Concrete Alternative Designed for 3D Printing Homes and Infrastructure

Researchers at Oregon State University (OSU) have developed a new fast-curing, environmentally friendly alternative to traditional concrete that could significantly change how buildings and infrastructure are constructed in the future. Designed specifically with 3D printing and rapid construction in mind, this innovative material addresses two major problems associated with conventional concrete: high carbon emissions and slow curing times.

As global population numbers continue to rise toward 8.5 billion, the pressure to build homes, shelters, and infrastructure quickly and sustainably has never been greater. Additive manufacturing, more commonly known as 3D printing, is already being explored as a solution to housing shortages and disaster-response construction. However, traditional concrete has proven to be a bottleneck in this process. OSU’s new material aims to remove that bottleneck altogether.

Why Traditional Concrete Is a Problem

Concrete is the most widely used construction material on Earth, but its environmental cost is enormous. The key issue lies in cement, the binding agent that holds concrete together. Cement production alone is responsible for around 8% of global carbon dioxide emissions. This is largely due to the energy-intensive process required to produce it, which involves heating limestone and other materials in industrial kilns to temperatures exceeding 1,400°C, often using fossil fuels.

Beyond emissions, concrete also takes a long time to cure. Standard cement-based concrete can require up to 28 days to reach its full structural strength. During that time, construction often needs additional support structures, formwork, and delays, all of which slow down building projects and increase costs. For 3D printing, where speed and material efficiency are critical, these limitations become even more problematic.

How the New Material Works

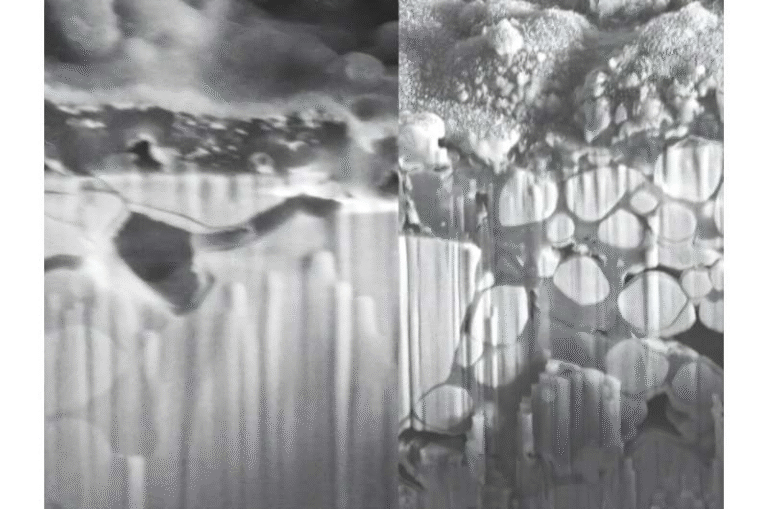

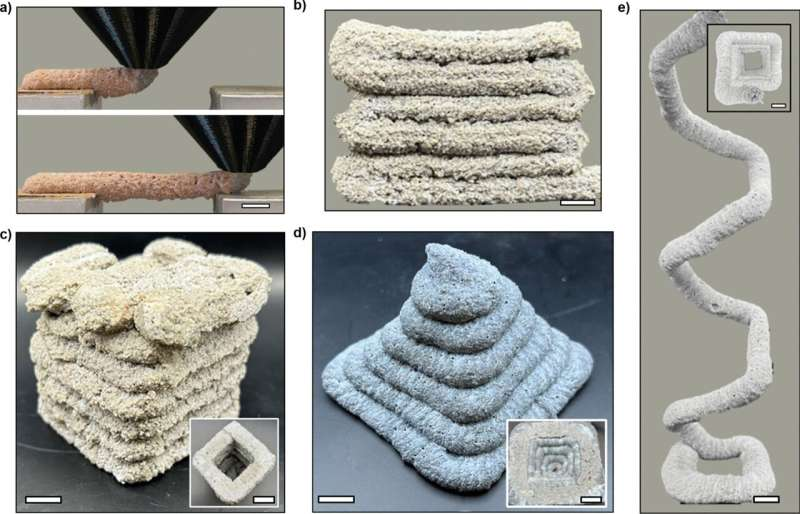

The OSU team developed a clay-based composite material that behaves very differently from conventional concrete. Instead of relying on cement, the material uses an acrylamide-based binding agent that triggers a chemical reaction known as frontal polymerization. This reaction allows the material to cure as it is being extruded from the 3D printer, rather than hours or days later.

This immediate curing gives the printed structure instant buildable strength, allowing it to support additional layers almost right away. The material achieves a strength of 3 megapascals immediately after printing, which is strong enough to construct multilayer walls and freestanding overhangs, including roof-like structures.

One of the most impressive features is that the material can be printed across unsupported gaps, such as the top edges of door and window openings. Traditional concrete printing often requires extra supports for these areas, but this new approach eliminates that need, making the printing process faster and more efficient.

Strength That Rivals Conventional Concrete

Speed alone would not matter if the final structure lacked durability. Fortunately, the OSU material performs exceptionally well in strength tests. Within just three days, it exceeds 17 megapascals, which is the minimum compressive strength required for residential structural concrete.

To put this in perspective, standard cement-based concrete may take four weeks or more to reach similar strength levels. This dramatic reduction in curing time opens the door to rapid construction projects, particularly in situations where time is critical, such as disaster relief or emergency housing.

What Makes It Environmentally Friendly

Another major advantage of the material is its low environmental footprint. Instead of cement, the mixture consists largely of locally available soil, combined with hemp fibers, sand, and biochar. Biochar is a carbon-rich material created by heating organic biomass, such as wood chips, under low-oxygen conditions. Not only does biochar reduce emissions, but it can also help lock carbon into the material, further improving sustainability.

By avoiding the high-temperature kiln process required for cement production, this new material significantly reduces energy consumption and carbon emissions. The researchers emphasize that the ingredients are widely available and renewable, making the technology more accessible across different regions.

Who Led the Research

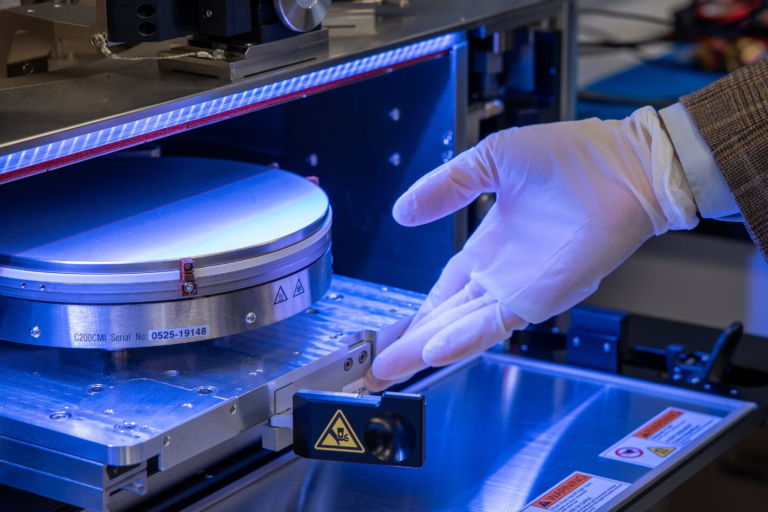

The research was led by Nicolas Gonsalves, a doctoral student at Oregon State University. The project was a transdisciplinary effort, bringing together expertise from multiple departments. Contributors included researchers from OSU’s School of Mechanical, Industrial and Manufacturing Engineering, the School of Civil and Construction Engineering, the College of Forestry, and the College of Agricultural Sciences.

This broad collaboration reflects the complexity of developing new construction materials that must meet mechanical, environmental, and structural requirements all at once.

Potential Uses in the Real World

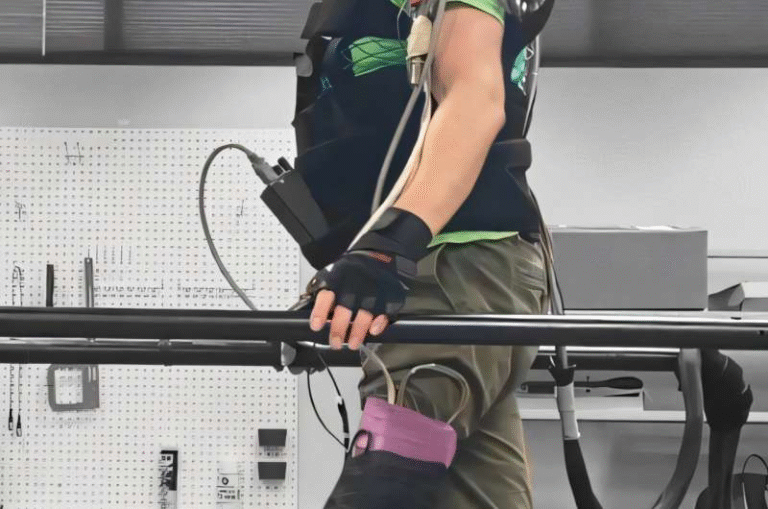

The ability to print strong structures quickly has obvious implications. The researchers see this material as especially useful for rapid housing construction, emergency shelters, and infrastructure rebuilding after natural disasters. With extreme weather events becoming more frequent, the need for fast and resilient building methods is growing.

Because the material can be 3D printed with minimal formwork and support structures, it could also reduce labor costs and construction waste, two major challenges in the building industry.

Current Limitations and What Comes Next

Despite its promise, the material is not yet ready for widespread use. At present, it is more expensive than standard cement-based concrete, and reducing costs is a key goal moving forward. Additionally, before it can be approved for construction projects, the material must undergo standardized testing under American Society for Testing and Materials (ASTM) guidelines.

The research team will also need to prepare detailed reports for review by professional engineers, a necessary step before the material can be incorporated into building codes and real-world projects.

A Broader Look at 3D Printing in Construction

3D printing in construction has gained attention worldwide for its potential to reduce material waste, lower labor demands, and speed up project timelines. However, materials have always been the limiting factor. Innovations like OSU’s clay-based composite show that the future of construction may depend as much on chemistry and materials science as on robotics and automation.

If materials like this can be produced at scale and approved by regulators, they could play a major role in building more sustainable cities and addressing global housing shortages.