A Self-Adapting Fiber Component Is Solving the Heat Problem in High-Power Thulium Fiber Lasers

High-power fiber lasers are everywhere today, from industrial cutting tools to medical devices and defense systems. Among them, thulium fiber lasers, which operate at a wavelength of 2 micrometers, hold special promise. They are safer when it comes to stray light, more suitable for certain materials, and highly attractive for next-generation laser systems.

Yet despite these advantages, thulium fiber lasers have been stuck at an output power of around 1 kilowatt for more than a decade. The main roadblocks have been nonlinear optical effects and, more critically, heat buildup inside fiber components. A new development from researchers at Fraunhofer IOF in Germany may finally offer a practical way past this long-standing limit.

The breakthrough centers on a deceptively simple but clever component known as a self-adapting cladding light stripper (CLS)—a part that plays a crucial role in keeping high-power fiber lasers stable and safe.

Why Heat Is Such a Big Problem in Thulium Fiber Lasers

To understand why this matters, it helps to know how fiber lasers work. In high-power fiber lasers, not all light stays neatly confined to the core of the fiber. Some of it travels in the outer cladding, where it is unwanted. If this stray light is not removed efficiently, it can degrade beam quality, reduce efficiency, and even damage laser components.

This is where the cladding light stripper comes in. Its job is to remove that unwanted light before it causes trouble.

For thulium fiber lasers, the challenge is especially severe. These lasers often use inband pumping, where pumping occurs at 1.9 micrometers instead of the more common 793 nanometers. Inband pumping is attractive because it improves efficiency and reduces overall heat generation. However, it also means that CLS components must handle very high optical powers at long wavelengths, which most traditional designs simply cannot tolerate.

Why Traditional CLS Designs Fall Short

Most conventional CLS devices rely on polymer-based coatings. While these work well at shorter wavelengths, they fail badly at 2 micrometers. Polymers absorb strongly at this wavelength, leading to intense localized heating. In practice, this means polymer CLS devices can burn out at just a few watts of stripped power.

Other approaches exist, such as etched fibers or laser-processed surfaces, which are more heat-resistant. However, these designs struggle to remove low-angle cladding light, which is particularly important for high-power pump lasers.

More advanced multimaterial CLS designs try to spread heat by layering materials with gradually changing refractive indices. While effective, these designs are complex, difficult to fabricate, and not well suited for rapid experimental setups.

The New Idea: A Self-Adapting Single-Material CLS

The Fraunhofer IOF team took a different approach. Instead of using multiple materials or complex structures, they developed a single-material CLS with self-adapting behavior.

The key lies in the material’s strongly negative thermo-optical coefficient. In simple terms, this means the material’s refractive index decreases as temperature increases.

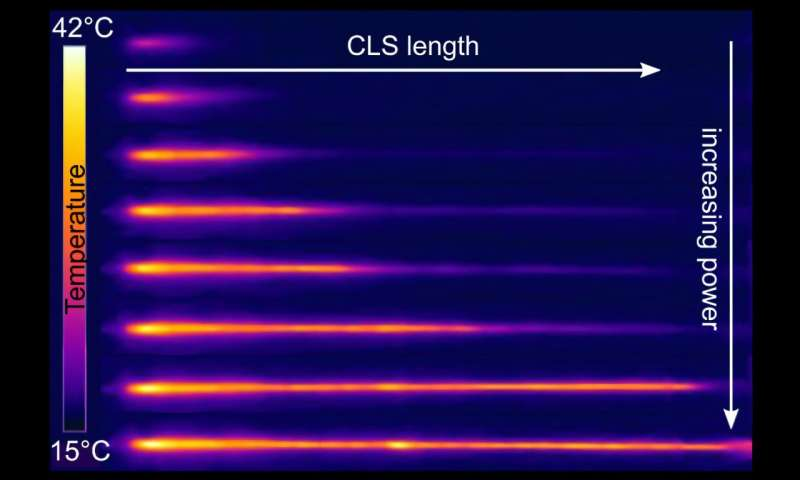

At low power, the refractive index of the CLS is slightly higher than that of the glass fiber, allowing it to strip cladding light efficiently. As optical power increases and the CLS heats up, the refractive index drops in the hottest regions. These regions then become less effective at stripping light, allowing some of the remaining cladding light to travel further along the fiber to cooler sections.

The result is a dynamic redistribution of heat along the length of the CLS instead of a dangerous thermal hotspot at the beginning. Crucially, this happens automatically, without any active control systems.

Experimental Results That Set New Benchmarks

The researchers validated their design using both numerical simulations and laboratory experiments. They tested fibers with 125 micrometer and 400 micrometer diameters, covering all wavelengths relevant to thulium fiber lasers.

The results are impressive:

- More than 20 watts of stripped signal light at 2 micrometers

- Up to 675 watts of stripped pump light at 793 nanometers

These figures represent record performance for single-material CLS designs at these wavelengths.

The team also found that bending the fiber improves stripping efficiency even further. With optimized bending, attenuation levels above 40 decibels were achieved, which is more than sufficient for high-power laser operation.

Equally important, the maximum temperature of the CLS did not rise significantly as input power increased. Instead of overheating, the system simply spread the thermal load over a longer fiber length, preventing damage.

Why This Matters for Breaking the 1 kW Barrier

For years, thulium fiber lasers have been limited not because the gain medium itself is incapable, but because supporting components could not handle the heat. The new self-adapting CLS directly addresses one of the most critical weak points in high-power designs.

By enabling robust and efficient stripping at challenging long wavelengths, this technology makes inband-pumped thulium lasers far more practical at higher powers. That, in turn, could help push these systems well beyond their long-standing 1 kilowatt ceiling.

The simplicity of the design also matters. A single-material CLS is easier to fabricate, easier to integrate, and well suited for quick laboratory experiments, where flexibility is often just as important as ultimate performance.

Applications Beyond Thulium Lasers

Although this CLS was designed with thulium fiber lasers in mind, the concept is not limited to 2 micrometers. By tuning the refractive index of the material, the same self-adapting principle can be applied to other laser systems, including:

- Erbium fiber lasers operating at 1.5 micrometers

- Ytterbium fiber lasers operating near 1 micrometer

This opens the door to more robust CLS designs across a wide range of high-power fiber laser platforms.

A Quick Look at Thulium Fiber Lasers and Their Importance

Thulium fiber lasers occupy a unique niche in photonics. Their longer wavelength is strongly absorbed by water, making them especially valuable for medical procedures such as soft-tissue surgery. In industrial settings, they are useful for processing plastics, composites, and certain metals. In defense and sensing applications, the 2 micrometer wavelength offers advantages in atmospheric transmission and eye safety.

As demand grows for higher power and better efficiency at this wavelength, innovations like the self-adapting CLS are becoming increasingly important.

A Practical Step Forward for High-Power Fiber Lasers

What makes this development stand out is not just the performance numbers, but the elegance of the solution. Instead of fighting heat with heavier cooling or more complicated structures, the Fraunhofer IOF team let the material itself do the work.

By allowing the CLS to adapt automatically to rising power, they have created a component that is both robust and scalable. For researchers and engineers working on next-generation fiber lasers, this could prove to be a very welcome tool.

As high-power fiber laser systems continue to evolve, small but smart innovations like this one may be exactly what’s needed to unlock the next level of performance.

Research paper:

https://doi.org/10.1117/1.apn.4.6.066005