New Research Reveals Why Single-Crystal Battery Materials Fail and How They Need a Rethink

Researchers from Argonne National Laboratory and the University of Chicago Pritzker School of Molecular Engineering (UChicago PME) have uncovered a critical flaw in how scientists have been thinking about battery degradation—specifically in single-crystal lithium-ion cathode materials that are increasingly used in electric vehicles and advanced energy storage systems. Their findings challenge long-held assumptions and show that simply switching to newer materials is not enough without rethinking how those materials behave at the nanoscale.

The study, published in Nature Nanotechnology in December 2025, addresses a persistent and costly problem in battery technology: capacity loss, shortened lifespan, and safety risks such as cracking and thermal runaway. While single-crystal cathodes were expected to solve many of these issues, real-world performance has often fallen short. This research explains why.

Why Cathode Cracking Matters So Much

Lithium-ion batteries rely heavily on the stability of their cathodes, the positive electrode that stores and releases lithium ions during charging and discharging. Over time, mechanical stress inside the cathode can lead to cracks, which allow the electrolyte to seep in and trigger unwanted chemical reactions. These reactions can reduce battery capacity, accelerate aging, and in extreme cases, cause fires.

Traditional lithium-ion batteries often use polycrystalline nickel-rich layered oxides, commonly referred to as PC-NMC cathodes (nickel–manganese–cobalt). These are made up of many tiny crystals packed together. As the battery cycles, these crystals expand and contract by about 5–10% in volume, eventually exceeding their elastic limits. This repeated stress widens grain boundaries, leading to cracking—much like potholes forming in roads after repeated freezing and thawing.

To address this, researchers turned to single-crystal NMC cathodes (SC-NMC), which lack grain boundaries and were expected to be far more mechanically stable. However, despite the theoretical advantages, these materials have not consistently delivered better performance.

The Wrong Assumptions Were Being Applied

The new research shows that the problem wasn’t with the idea of single-crystal cathodes—it was with the assumptions borrowed from polycrystalline materials. Scientists had been designing single-crystal cathodes using the same principles that work for polycrystals, assuming the same failure mechanisms applied.

According to the research team, this assumption was fundamentally flawed.

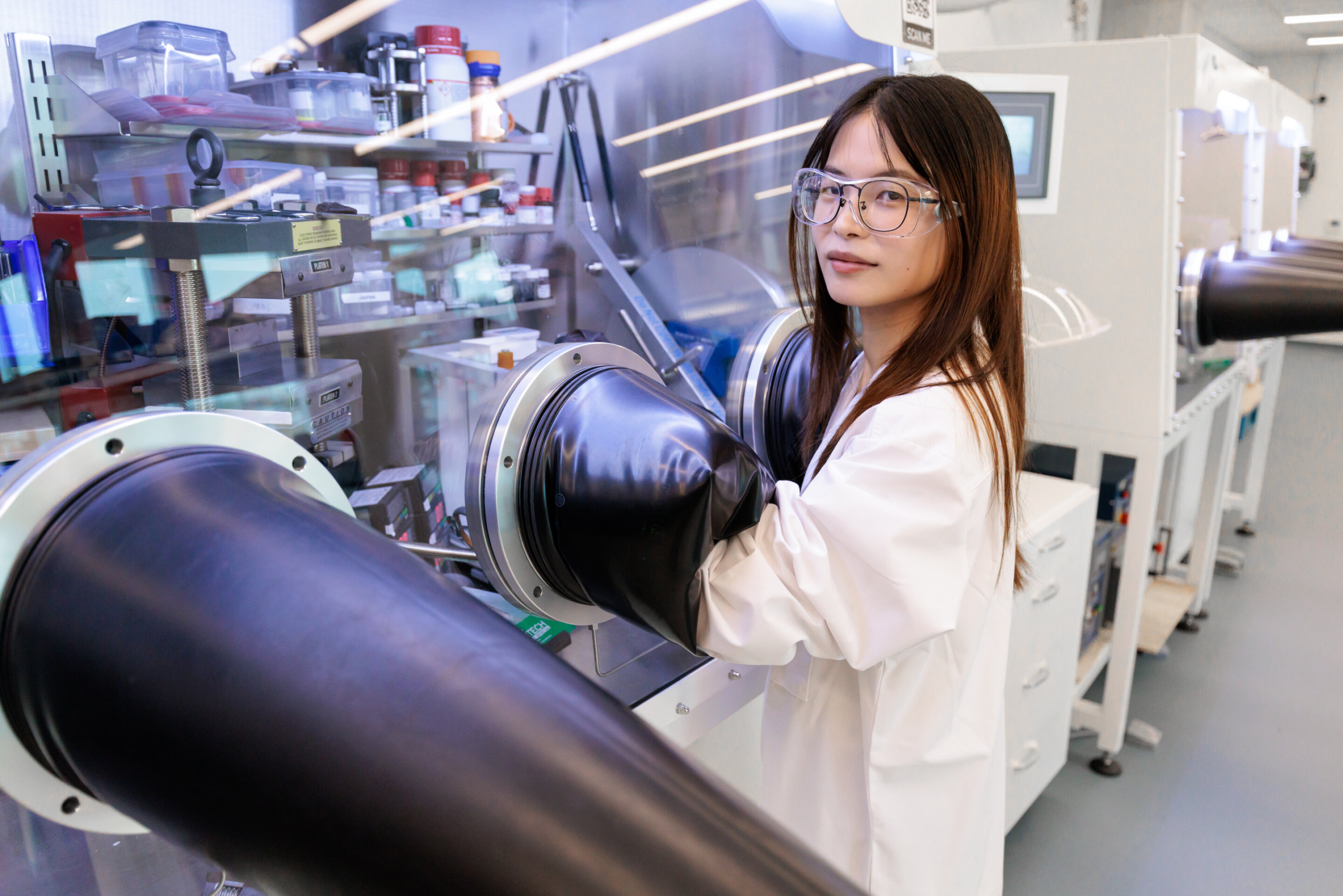

The study’s lead author, Jing Wang, conducted the research during her Ph.D. at UChicago PME through the Graduate Research Collaborative (GRC) program, jointly supervised by Shirley Meng’s Laboratory for Energy Storage and Conversion and Khalil Amine’s Advanced Battery Technology team at Argonne. Wang is now a postdoctoral researcher continuing her work in this area.

The team found that single-crystal cathodes fail through a completely different mechanical process than polycrystalline ones. Instead of cracks forming along grain boundaries, cracking in single-crystal materials originates within a single particle itself.

A New Degradation Mechanism Comes Into Focus

Using multi-scale synchrotron X-ray techniques and high-resolution transmission electron microscopy, the researchers were able to observe what was happening inside single-crystal particles during electrochemical cycling.

What they discovered was reaction heterogeneity. Different regions within the same crystal particle react at different rates during charging and discharging. This uneven reaction creates localized nanoscopic strain, which builds up over time. Instead of stress being distributed across multiple crystals, the stress accumulates internally, eventually causing cracks to form from the inside out.

This mechanism had been largely overlooked in previous studies, yet it turns out to be the dominant driver of degradation in single-crystal cathodes.

The findings establish a direct link between material composition and mechanical degradation pathways, offering a much clearer explanation for why these batteries lose performance despite lacking grain boundaries.

Rethinking Nickel, Manganese, and Cobalt

One of the most striking outcomes of the study is how it redefines the roles of cobalt and manganese in battery cathodes.

In polycrystalline cathodes, cobalt is known to promote cracking, but it has traditionally been included to reduce lithium–nickel disorder, a structural problem that harms performance. Manganese, on the other hand, has been viewed as mechanically beneficial and cost-effective.

For single-crystal cathodes, the situation is reversed.

To test this, the team built and evaluated two experimental battery chemistries:

- A nickel–cobalt cathode with no manganese

- A nickel–manganese cathode with no cobalt

The results were clear. In single-crystal systems, manganese caused more mechanical damage, while cobalt actually helped extend battery life by improving mechanical stability.

This finding overturns conventional wisdom and shows that material choices must be tailored specifically to single-crystal designs, rather than inherited from polycrystalline systems.

The Cost Challenge and What Comes Next

While cobalt improves performance in single-crystal cathodes, it also presents a major challenge: cost. Cobalt is significantly more expensive than nickel or manganese and comes with supply chain and ethical concerns.

The researchers emphasize that the next step is to identify lower-cost materials that can replicate cobalt’s stabilizing effects without relying heavily on it. This could involve new elemental substitutions, compositional gradients, or entirely new cathode architectures.

Despite the challenges, the researchers see this work as a crucial step forward. By identifying the correct degradation mechanism, future studies can focus on design strategies that actually address the real problem, rather than treating symptoms based on outdated assumptions.

Why This Matters for Electric Vehicles and Energy Storage

Battery reliability is central to the electrification of society. Electric vehicles, grid-scale storage, and renewable energy systems all depend on batteries that are safe, durable, and long-lasting. Even small improvements in cathode stability can translate into years of additional battery life and significant reductions in cost.

This research helps explain why some promising battery materials failed to meet expectations and provides a roadmap for designing better cathodes. By understanding how different materials degrade at the nanoscale, scientists can build a new generation of batteries that are not only more powerful, but also more trustworthy.

The study also highlights the importance of collaboration between universities, national laboratories, and industry partners. Programs like the GRC and networks such as UChicago’s Energy Transition Network played a key role in enabling this work, bringing together expertise from multiple disciplines.

A Broader Lesson for Materials Science

Beyond batteries, this research serves as a reminder that materials cannot be treated as interchangeable parts. Changing from polycrystalline to single-crystal structures fundamentally alters how stress, strain, and chemical reactions interact. Design rules must evolve accordingly.

As battery technology continues to advance, insights like these will be essential for avoiding costly dead ends and accelerating progress toward cleaner, more reliable energy systems.

Research paper:

Nanoscopic strain evolution in single-crystal battery positive electrodes

https://doi.org/10.1038/s41565-025-02079-9