A New Transparent Window Insulation Material Could Dramatically Cut Building Energy Loss

Researchers at the University of Colorado Boulder have developed a new type of window insulation that could significantly improve how buildings manage heat—without blocking natural light or outdoor views. The material, called MOCHI, short for Mesoporous Optically Clear Heat Insulator, is designed to solve one of the biggest challenges in energy-efficient construction: how to insulate windows as effectively as walls while keeping them transparent.

Buildings around the world are responsible for about 40% of global energy consumption, much of it tied to heating and cooling. A large portion of that energy is lost or gained through windows, which are far less insulated than walls or roofs. Traditional window insulation options often sacrifice clarity, making interiors darker or views cloudy. MOCHI aims to change that balance by offering high thermal insulation with near-perfect transparency.

What Exactly Is MOCHI?

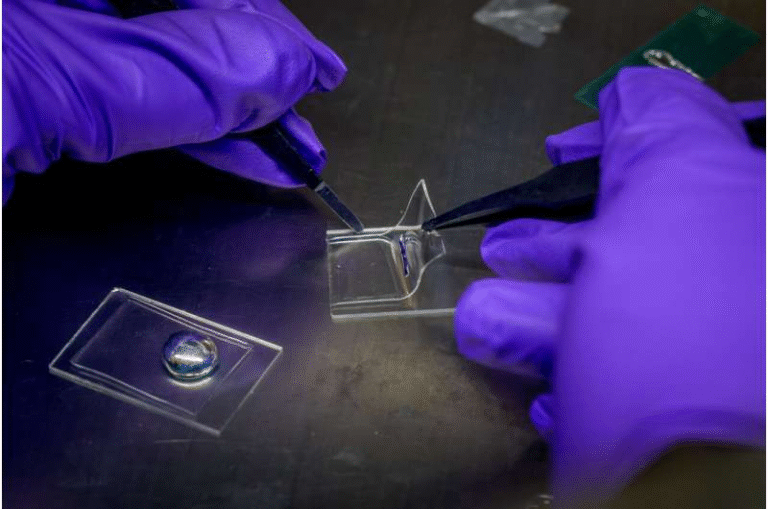

MOCHI is a silicone-based gel material engineered with an intricate internal structure that traps air extremely efficiently. It can be produced as thin sheets or thicker panels, depending on the application, and is designed to be applied to the inside surface of existing windows. While the material is not yet commercially available and is currently made only in laboratory conditions, early results suggest it could be both durable and long-lasting.

What sets MOCHI apart is that it is almost completely transparent, reflecting only about 0.2% of incoming visible light. This makes it far clearer than most insulating materials currently on the market, many of which scatter light and appear hazy.

Why Transparent Insulation Is So Difficult

Insulating walls is relatively straightforward: thickness and opacity are not major concerns. Windows, however, must allow light to pass through clearly. Many traditional insulating materials work by trapping air, but the structures that do this effectively often scatter light. This tradeoff is why highly insulating materials like foams and aerogels are rarely used in clear window applications.

The research team, led by physics professor Ivan Smalyukh, set out to overcome this limitation by designing a material that controls air pockets at an extremely fine scale—small enough to block heat transfer without interfering with light.

The Science Behind the Material

At its core, MOCHI is built around a network of microscopic pores filled with air. These pores are many times thinner than the width of a human hair and make up more than 90% of the material’s total volume. The silicone framework surrounding them provides structural stability while maintaining optical clarity.

Heat normally moves through gases when energized molecules collide with one another and pass along energy. In MOCHI, the pores are so small that gas molecules cannot freely collide with each other. Instead, they repeatedly hit the walls of the pores, dramatically reducing heat transfer. This physical effect limits both conduction and convection, two major ways heat travels.

To demonstrate this insulating ability, researchers showed that a sheet just 5 millimeters thick could block enough heat that a flame could be held on one side while the other side remained cool enough to touch.

How MOCHI Is Made

The manufacturing process is complex and carefully controlled. It begins with mixing special surfactant molecules into a liquid solution. These surfactants naturally assemble into long, thread-like structures, similar to how oil separates from vinegar in salad dressing. Silicone molecules in the same solution then attach themselves around these threads.

Through a multi-step process, the surfactant structures are later removed and replaced with air. What remains is a highly ordered network of tiny, air-filled channels, all encased in silicone. The resulting structure has been compared to a “plumber’s nightmare” due to its dense and interconnected pathways.

This precise arrangement is what allows MOCHI to outperform many existing materials. Unlike aerogels, which also trap air but do so in a more random way, MOCHI’s structure is uniform and controlled, preventing the light scattering that causes cloudiness.

How MOCHI Compares to Aerogels

Aerogels are among the best-known insulating materials and are already used in demanding environments, including NASA’s Mars rovers, to protect sensitive electronics. However, aerogels typically look cloudy or smoky because their internal pores scatter light in many directions.

MOCHI takes inspiration from aerogels but improves on them by engineering pore size and distribution with extreme precision. This allows MOCHI to remain visually clear while offering comparable, and in some cases superior, insulation performance.

Potential Uses Beyond Windows

While window insulation is the most obvious application, the researchers see broader possibilities. MOCHI could be used in transparent building envelopes, skylights, and even specialized devices designed to capture and retain solar heat. For example, systems could be built to collect sunlight during the day and store that heat for warming water or interior spaces, even under partially cloudy conditions.

Because the material allows light through while trapping heat, it could play a role in passive solar energy systems, reducing reliance on fossil fuels and cutting utility costs.

Challenges to Commercialization

Despite its promise, MOCHI is still far from store shelves. The current production method is time-intensive and suited only for laboratory-scale fabrication. Scaling up the process to industrial levels will require significant engineering work.

That said, the researchers are optimistic. The raw ingredients used to make MOCHI are relatively inexpensive, and Smalyukh believes that the manufacturing process can be streamlined with further development. If those hurdles are overcome, MOCHI could become a practical and cost-effective solution for improving building efficiency.

Why This Matters for Energy and Climate Goals

Heating and cooling buildings accounts for a massive share of global energy use and carbon emissions. Even small improvements in window insulation can lead to substantial energy savings when applied across millions of buildings. By addressing one of the weakest points in building envelopes, MOCHI could contribute meaningfully to efforts aimed at reducing energy waste and improving indoor comfort.

Importantly, the material does this without asking occupants to compromise on daylight, aesthetics, or views, which has long been a barrier to adopting high-performance window insulation.

The Road Ahead

For now, MOCHI remains a research-stage material, but its performance has already attracted significant attention within the scientific community. The work was published in the journal Science, underscoring its credibility and potential impact.

If future research succeeds in simplifying production and proving long-term durability in real-world conditions, MOCHI could represent a major shift in how windows are designed and retrofitted. In a world increasingly focused on sustainability, innovations like this show that energy efficiency and comfort do not have to be at odds.

Research paper:

https://www.science.org/doi/10.1126/science.adx5568