Ancient Board Game Tactics Help AI Unlock Smarter Cooling Strategies for Modern Machines

When machines run on electricity or fuel, heat buildup is unavoidable. From power grids and jet engines to data centers and high-performance electronics, managing that heat efficiently is one of the biggest engineering challenges today. A new research study shows that help can come from an unexpected place: an ancient board game called Go.

Researchers have developed an artificial intelligence approach inspired by Go’s strategic logic to better understand and optimize spray cooling, a widely used technique for rapidly removing heat from high-power systems. The work blends mechanical engineering, thermofluid science, and machine learning, offering a clearer roadmap for designing more reliable and efficient cooling systems.

Why Cooling Matters More Than Ever

Modern infrastructure is packed with systems that generate intense heat. Electrical grids can fail during heat spikes, servers in data centers risk shutdowns if temperatures climb too high, and turbines or engines can suffer serious damage without proper thermal control. As machines become smaller, faster, and more powerful, traditional cooling methods struggle to keep up.

One of the most effective solutions engineers use is spray cooling. This technique involves spraying a liquid—often water or a specialized fluid—onto a hot surface. The liquid breaks into countless tiny droplets, which absorb heat rapidly as they boil and evaporate. This process can remove heat far more efficiently than solid heat sinks or air cooling.

Despite its effectiveness, spray cooling is not easy to optimize. Its performance depends on a complex web of factors, including droplet size, nozzle design, fluid properties, flow rates, and surface temperature. Tweaking one variable can affect several others, making trial-and-error experimentation slow and expensive.

How an Ancient Game Sparked a New Idea

The inspiration for tackling this complexity came from Go, a strategy board game invented in China more than 2,500 years ago. Go is known for its deceptively simple rules and astonishing strategic depth. Players aim to control territory on a grid by carefully placing stones, with success depending on understanding how individual moves interact across the entire board.

Interest in Go surged globally after the release of AlphaGo, an AI system that defeated professional human players by learning patterns and strategies far beyond traditional programming. Watching AI master such a complex, interconnected system led one of the researchers, mechanical engineer Jiangtao Cheng, to think differently about engineering problems.

Spray cooling systems, much like a Go board, involve interconnected dynamics. Droplets interact with surfaces, fluids behave differently under heat, and small changes can ripple across the entire system. This parallel sparked the idea that AI strategies used in Go could be adapted to thermal management.

Using AI to Tame Spray Cooling Complexity

To put this idea into practice, Cheng and his collaborators—Assistant Professor Zhenhua Tian and Ph.D. candidate Mohammad Shamsodini Lori—turned to machine learning. Instead of conducting new experiments from scratch, they performed a large-scale meta-analysis of existing research.

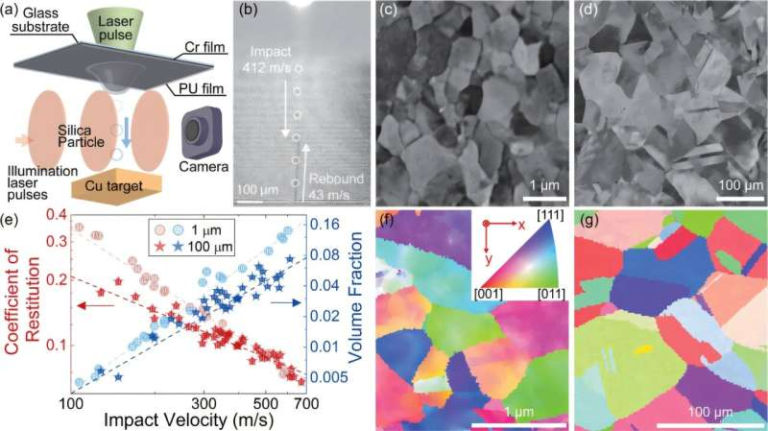

The team gathered data from 25 previously published spray cooling studies, covering a wide range of operating conditions, fluids, nozzle geometries, and thermal loads. This dataset included critical parameters such as droplet diameter, Reynolds number, fluid viscosity, surface temperature, and heat flux.

Using this information, the researchers trained multiple machine learning models to identify how these variables interact and which combinations lead to the most effective cooling. Rather than focusing on isolated factors, the AI examined the entire system as a network, similar to evaluating the whole Go board instead of a single move.

This approach allowed the models to uncover patterns that traditional empirical formulas often miss.

Why Droplets Make Spray Cooling So Effective

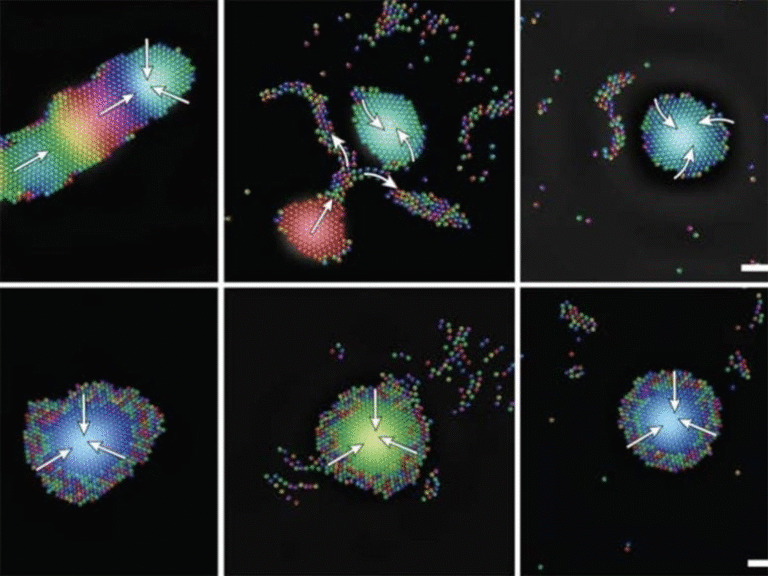

At the heart of spray cooling is the behavior of individual droplets. When a droplet hits a hot surface, it absorbs heat almost instantly. If conditions are right, it boils or evaporates, carrying heat away in the form of latent energy.

Smaller droplets tend to heat up and evaporate faster, but they can also be deflected by airflow or fail to reach the surface. Larger droplets deliver more liquid but may not evaporate as efficiently. The balance between droplet size, velocity, and fluid properties is crucial.

The AI models developed in this study were able to analyze how these competing effects interact, helping to predict optimal droplet characteristics for different cooling scenarios. This insight is particularly valuable for designing spray nozzles and selecting appropriate cooling fluids.

What the AI Models Revealed

By comparing different machine learning techniques, the researchers found that AI-based models consistently outperformed traditional correlations used in spray cooling design. In some cases, prediction errors were reduced to below a few percent, a significant improvement over older methods.

The models also highlighted which parameters matter most under specific conditions. For example, certain fluid properties dominate performance at high heat fluxes, while nozzle geometry becomes more important in other regimes. These insights can guide engineers toward smarter design choices without exhaustive physical testing.

Importantly, the team also used interpretability tools to understand why the AI made certain predictions. This step helps bridge the gap between black-box algorithms and practical engineering knowledge.

Cutting Down Trial and Error

One of the biggest advantages of this AI-driven approach is efficiency. Physical experiments in spray cooling can be costly, time-consuming, and difficult to control precisely. By narrowing down the most promising configurations in advance, AI can dramatically reduce the number of experiments needed.

This means faster development cycles, lower costs, and quicker deployment of improved cooling solutions for real-world systems such as data centers, engines, turbines, and power electronics.

Broader Implications for Engineering

This research goes beyond spray cooling. It demonstrates how AI techniques inspired by game strategy can be applied to complex physical systems with many interacting variables. Similar approaches could be used in areas like combustion optimization, materials design, fluid transport, and energy systems.

By combining domain knowledge with data-driven models, engineers can move from intuition-based design toward holistic, system-level optimization.

A Closer Look at Spray Cooling Applications

Spray cooling is already used in several high-stakes environments:

Data centers: High-density servers generate enormous heat loads. Advanced spray cooling could help reduce energy consumption and prevent outages.

Aerospace and automotive engines: Efficient heat removal improves performance, reliability, and lifespan.

Power electronics: Devices like inverters and converters operate at high power densities and benefit from rapid, controllable cooling.

As these technologies continue to evolve, demand for precise thermal management will only grow.

Where the Research Goes Next

The current study focuses on predictive modeling using existing data. The next step is experimental validation, where the AI-generated recommendations are tested in real spray cooling setups. If the predictions hold up, they could directly influence how future cooling systems are designed and deployed.

By merging thermofluid science with artificial intelligence, the researchers are helping redefine how engineers approach one of the most fundamental challenges in modern technology: keeping machines cool, reliable, and efficient.

Research paper:

Thermohydraulic Performance of Spray Cooling Systems A General Model by Machine Learning

https://link.springer.com/article/10.1007/s10462-025-11446-w