Tougher Solid Electrolyte Brings Long-Sought Lithium Metal Batteries Closer to Reality

For decades, lithium metal batteries have been something of a holy grail in energy storage. In theory, they promise far higher energy density, faster charging, and improved safety compared to today’s lithium-ion batteries. In practice, however, one stubborn materials problem has repeatedly held them back. Now, researchers at Stanford University believe they’ve found a surprisingly elegant way around it—by strengthening solid electrolytes with an ultrathin layer of silver.

At the heart of this advance is a fundamental shift in how scientists think about protecting fragile solid electrolytes. Instead of trying to manufacture flawless ceramic materials—an almost impossible task at scale—the Stanford team focused on reinforcing the surface where failure typically begins.

Why Solid Electrolytes Matter for Lithium Metal Batteries

Most commercial batteries today rely on liquid electrolytes to shuttle lithium ions between the cathode and anode. While effective, these liquids are flammable and limit how much energy a battery can safely store. Replacing them with solid electrolytes could eliminate fire risks and allow the use of pure lithium metal anodes, which store far more energy than graphite.

The challenge is that many promising solid electrolytes are ceramic materials. They conduct lithium ions well, but they are also brittle. Under repeated charging and discharging—or even during manufacturing—tiny cracks form. Over time, these microscopic defects grow until the battery fails.

One particularly problematic outcome is lithium intrusion. Lithium can burrow into nano-scale cracks, forming filament-like structures that worsen the damage and eventually short-circuit the battery.

The Specific Material Under Study: LLZO

The Stanford researchers focused on a well-known solid electrolyte called LLZO, short for lithium lanthanum zirconium oxide. LLZO has long been considered a strong candidate for solid-state batteries because it combines high lithium-ion conductivity with good chemical stability against lithium metal.

But LLZO’s Achilles’ heel is its mechanical weakness. Even under moderate pressure, its crystalline structure can develop surface flaws that later turn into catastrophic fractures.

Previous research—including work published by the same team in 2023—had already mapped out how these cracks form and spread. That earlier insight laid the groundwork for the new breakthrough.

A Thin Silver Layer Makes a Big Difference

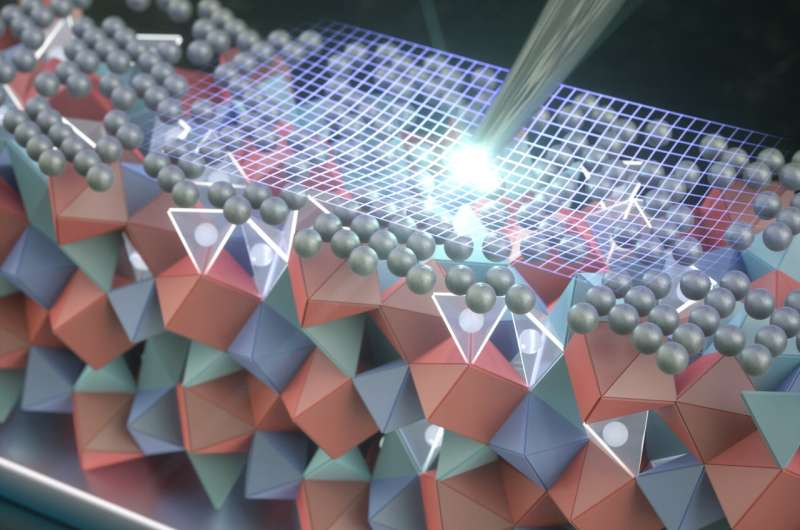

The new study took an unconventional approach. Instead of coating LLZO with metallic silver for electrical reasons, the team used silver ions (Ag⁺) to change how the ceramic behaves mechanically.

Here’s what they did:

- They deposited a 3-nanometer-thick layer of silver onto the surface of LLZO.

- The coated samples were then annealed at 300°C (572°F).

- During heating, silver atoms diffused into the surface of the electrolyte, penetrating roughly 20 to 50 nanometers deep.

- In the process, silver ions replaced some lithium ions in the crystal lattice.

Crucially, the silver remained in an ionic, dissolved state, rather than forming metallic silver clusters. According to the researchers, this distinction is key. Ionic silver fundamentally alters how cracks initiate and propagate in the ceramic.

Dramatically Improved Resistance to Cracking

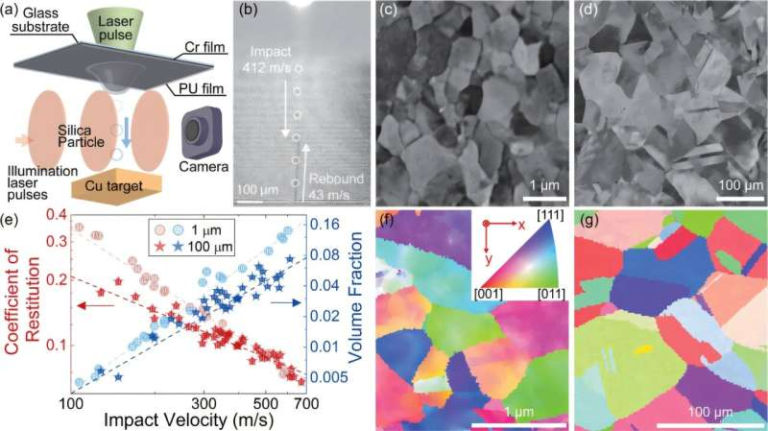

Using a specialized mechanical probe inside a scanning electron microscope, the team measured how much force was required to fracture the electrolyte surface.

The result was striking. The silver-treated LLZO required nearly five times more pressure to crack compared to untreated samples.

Even more important, existing surface imperfections became far less dangerous. The presence of silver ions reduced lithium’s tendency to invade nano-scale flaws—especially during fast charging, when mechanical and electrochemical stresses are highest.

In practical terms, this means that tiny surface defects are far less likely to turn into battery-killing fractures.

Why Surface Protection Beats Perfection

A real-world solid-state battery isn’t a single flawless crystal. It’s a stack of layers—cathode, electrolyte, and anode—pressed together. Producing these layers without even microscopic defects would be extraordinarily expensive and likely unrealistic at commercial scales.

That’s why this approach is so appealing. Instead of demanding perfection, the silver treatment toughens the most vulnerable region: the surface.

By reinforcing just the outer tens of nanometers, the electrolyte becomes more tolerant of inevitable manufacturing flaws and mechanical stress.

Not Just Silver, but Silver Works Best

Interestingly, silver isn’t the only metal that can have this effect. The researchers tested other metal ions, including copper, which also improved fracture resistance—though not as effectively as silver.

The key requirement is that the metal ions be larger than lithium ions. Their presence disrupts crack formation and alters stress distribution within the ceramic structure.

This opens the door to future exploration of alternative materials that may be cheaper or more abundant than silver, while still delivering similar benefits.

What This Means for Battery Performance

If this technique proves scalable, the implications are significant:

- Higher energy density from lithium metal anodes

- Faster charging without triggering destructive lithium intrusion

- Improved safety, thanks to the elimination of flammable liquid electrolytes

- Longer battery lifetimes, due to reduced mechanical failure

However, the researchers are careful not to overstate the immediate impact.

So far, the experiments were conducted on localized regions of small samples, not on full battery cells. The next step is integrating this surface treatment into complete solid-state batteries and testing them over thousands of charge cycles.

Ongoing and Future Research Directions

The Stanford team is now expanding its work in several directions:

- Testing full lithium metal solid-state cells with controlled mechanical pressure applied from different angles

- Studying other classes of solid electrolytes, including sulfur-based materials, which may offer better chemical compatibility with lithium

- Exploring whether similar surface-doping strategies could benefit sodium-based batteries, which could help ease lithium supply constraints

If successful, these efforts could influence not just electric vehicles, but also grid-scale energy storage and portable electronics.

Why This Advance Stands Out

What makes this research especially compelling is its simplicity. Rather than relying on exotic new materials or complex architectures, it uses an ultrathin surface treatment to address one of the most stubborn problems in solid-state batteries.

It also underscores an important lesson in materials science: sometimes, small changes at the nanoscale can have outsized effects on real-world performance.

While challenges remain before commercialization, this silver-based toughening strategy marks a meaningful step toward making lithium metal batteries practical, durable, and safe.

Research Paper:

Heterogeneous doping via nanoscale coating impacts the mechanics of Li intrusion in brittle solid electrolytes, Nature Materials (2026)

https://www.nature.com/articles/s41563-025-02465-7