How Copper Smelters Accidentally Discovered the Path to the Iron Age

A new study by researchers from Cranfield University has shed fresh light on one of the most pivotal moments in human technological history — the birth of the Iron Age. The research suggests that ancient copper smelters, while trying to refine their copper production, may have unintentionally set humanity on the path to ironmaking.

This finding comes from the re-examination of a 3,000-year-old smelting site in Kvemo Bolnisi, located in southern Georgia. The site, originally excavated in the 1950s, was once believed to be an early iron production workshop. However, the latest analysis, published in the Journal of Archaeological Science in September 2025, challenges that idea and instead paints a different, and fascinating, picture of human experimentation at the edge of innovation.

The Rediscovery of Kvemo Bolnisi

Kvemo Bolnisi isn’t a new archaeological site. It was first studied during the Soviet period, when archaeologists uncovered large heaps of hematite — an iron oxide mineral — and slag, the byproduct of smelting. Because of the visible iron oxides, the early researchers assumed this was a primitive iron-smelting facility, marking a transitional stage between the Bronze and Iron Ages.

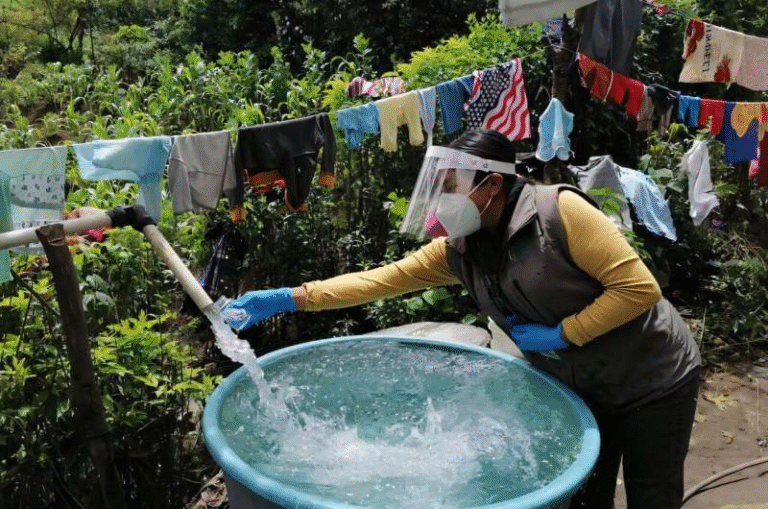

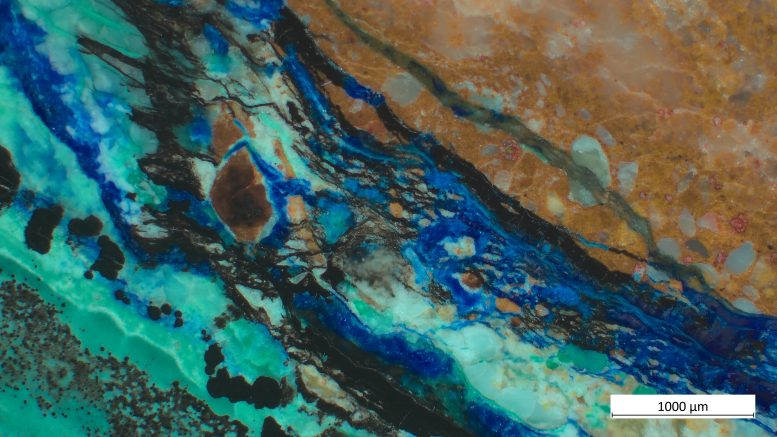

But decades later, a new team led by Dr. Nathaniel Erb-Satullo, a specialist in archaeological science at Cranfield University, revisited the site. Using modern analytical techniques — including scanning electron microscopy, chemical analysis, and mineralogical testing — the researchers discovered that the smelters at Kvemo Bolnisi were not producing iron at all.

Instead, these ancient metallurgists were working copper ores that were naturally low in iron content. To improve their yield and efficiency, they deliberately added hematite into their furnaces. The hematite acted as a flux — a material that helps impurities separate from the molten metal more easily.

This practice, the team realized, was not about ironmaking but about enhancing copper production. Yet, in doing so, these Bronze Age smelters were experimenting with the very materials and reactions that would eventually lead to the invention of iron smelting.

How Iron Oxide Helped Refine Copper

In metalworking, flux plays a crucial role in refining metals. By lowering the melting point of impurities, it allows molten metal to separate more efficiently from waste material. In the case of the Kvemo Bolnisi workshop, the smelters used iron oxide (hematite) for this exact purpose.

Since their copper ores lacked natural iron, adding hematite provided the missing ingredient to make the smelting process more effective. It made the molten slag more fluid and helped the copper metal pool and separate more completely from the rocky impurities.

The researchers analyzed slag samples under an electron microscope and found chemical and structural evidence consistent with copper smelting, not iron reduction. This proves that while iron was present in the process, it was never the final product.

Still, this seemingly small decision — to add iron oxide — is of enormous historical importance. It shows that ancient metallurgists were intentionally using and understanding iron-bearing minerals, centuries before iron was smelted as a metal in its own right.

Copper Workers: The Accidental Pioneers of Iron

The new findings strongly support a long-held theory in archaeology: that ironworking grew out of copperworking. Instead of being a sudden leap forward, the shift from the Bronze Age to the Iron Age may have been an incremental progression, built on centuries of trial, error, and curiosity.

By experimenting with materials like hematite, ancient smelters learned how iron-rich rocks behaved under heat and reduction. They became familiar with iron oxides as distinct materials with their own properties. Eventually, under the right furnace conditions — higher temperatures and a more reducing atmosphere — these experiments could have accidentally produced metallic iron.

Once that happened, it would only be a matter of time before people began refining the process deliberately. Thus, the Iron Age might have started not through direct intention, but as an unexpected consequence of copper smelting innovation.

From Meteoric Iron to Industrial Power

Before extractive iron metallurgy emerged, humans already knew of iron — but only in its meteoritic form. Fragments of meteoric iron, which fell to Earth from space, were sometimes hammered into tools or ornaments.

A famous example is Tutankhamun’s dagger, which dates back to around 1350 BCE. The blade was made from iron, but it came from a meteorite, not from ore. Because of its rarity, this metal was more valuable than gold in the Bronze Age.

However, meteoritic iron was extremely limited. It wasn’t until humans learned to extract iron from iron ore that the metal became widely available. This was a transformative moment: iron is one of the most abundant elements on Earth, and mastering its production opened the door to new tools, weapons, and infrastructure.

The Iron Age didn’t arrive overnight. It evolved gradually, as metalworkers learned to achieve the higher temperatures and chemical control needed to turn iron ore into usable metal. Once that knowledge spread, it fueled civilizations — from the Assyrian armies wielding iron weapons to the Roman builders constructing iron-reinforced structures, and later, the Industrial Revolution, which depended on steel and iron rails, engines, and machinery.

The discoveries at Kvemo Bolnisi give us a glimpse into how this transformation may have begun — not as a grand invention, but as the slow accumulation of metallurgical know-how by ancient copper artisans.

Reinterpreting a Misunderstood Site

When the Kvemo Bolnisi site was first discovered, researchers in the 1950s didn’t have access to the microanalytical tools available today. The large piles of hematite and slag made them think the site was producing early iron.

Dr. Erb-Satullo’s team relocated the site using hand-drawn maps from a 1964 Soviet publication and collected new samples for analysis. The microscopic examination revealed no metallic iron, but clear traces of copper extraction processes.

This updated interpretation demonstrates how modern materials science can rewrite our understanding of ancient technology. The study highlights that what was once thought to be an iron workshop was actually a sophisticated copper operation, reflecting both technical ingenuity and the spirit of experimentation.

The People Behind the Study

The research was conducted by Dr. Nathaniel L. Erb-Satullo and Dr. Bobbi W. Klymchuk, both of whom specialize in ancient metallurgical science. Their collaboration brought together methods from archaeology, geology, and materials science to reconstruct the smelting techniques used 3,000 years ago.

The project received funding from several organizations, including the British Institute of Ankara, the Gerda Henkel Foundation, and the American Research Institute of the South Caucasus.

Their work shows how interdisciplinary approaches — combining chemistry, geology, and archaeology — can unlock insights into the daily practices of ancient metalworkers, whose curiosity and experimentation quietly changed the course of human history.

Understanding Iron Metallurgy: A Broader Perspective

To appreciate the significance of this study, it helps to understand what iron metallurgy actually involves. Unlike copper or bronze, which melt relatively easily, iron requires much higher temperatures to smelt — typically above 1,200°C — and must be processed in a reducing environment, where oxygen is limited.

This makes ironworking much more challenging than copper smelting. Early metalworkers needed to control furnace airflow, fuel quality, and the ratio of carbon to ore — all without modern instruments. Achieving these conditions by accident while refining copper is not far-fetched.

The Caucasus region, where Kvemo Bolnisi is located, is known for its rich mineral resources and long history of mining. This area could have served as a technological crossroads, where experimentation and cultural exchange contributed to major metallurgical innovations.

What This Means for Archaeology

This discovery forces scholars to rethink how technological revolutions happen. It suggests that innovation is often cumulative, not sudden. The people of Kvemo Bolnisi were not trying to invent a new metal — they were simply optimizing their process. Yet their practical problem-solving and willingness to experiment had consequences that echoed through millennia.

Moreover, it highlights the importance of revisiting old archaeological sites with new technology. Artifacts that were once misunderstood can tell entirely new stories when examined through modern analytical methods.

The Kvemo Bolnisi study also deepens our appreciation for ancient craftspeople. They were not primitive laborers but skilled materials scientists of their time, constantly experimenting with ores, minerals, and furnaces to improve their results.

A Spark That Changed the World

The findings from Kvemo Bolnisi don’t just fill a gap in the archaeological record — they reshape how we understand one of humanity’s most transformative technological shifts.

By adding iron oxide to improve copper yields, these ancient smelters unknowingly laid the foundation for extractive iron metallurgy. It’s a perfect example of how human innovation often begins with curiosity and experimentation, rather than deliberate invention.

From those glowing furnaces in the Caucasus hills to the iron swords of Assyria and the steel skyscrapers of modern cities, the line of progress is surprisingly continuous. And it may all trace back to a few ancient copper smelters who, three millennia ago, simply wanted to make their metal a little bit better.

Research Reference:

Iron in copper metallurgy at the dawn of the Iron Age: Insights on iron invention from a mining and smelting site in the Caucasus (Journal of Archaeological Science, 2025)