Scientists Measure a Fraction of an Electron, Unlocking a Century-Old Secret of Catalysis

For more than a hundred years, scientists have known that catalysts—the materials that speed up chemical reactions—work because of the way they share electrons with the molecules they interact with.

Yet no one had ever managed to measure that tiny fraction of an electron being shared. Now, researchers from the University of Minnesota Twin Cities and the University of Houston have done exactly that. They have not only observed but also quantified the fractional electron transfer that powers catalytic reactions. Their new technique, called Isopotential Electron Titration (IET), could reshape the way we understand and design catalysts for everything from fuel production to pharmaceuticals.

This discovery was published in ACS Central Science and is already being hailed as a major step forward in the field of catalysis. It offers an explanation for why precious metals like gold, silver, and platinum perform so effectively and provides researchers with a tool to develop new materials that could make manufacturing cleaner, faster, and more efficient.

What Catalysts Actually Do

A catalyst is a material that helps a chemical reaction occur more easily. It doesn’t get consumed in the process but lowers the activation energy needed for the reaction to happen. Because of this, catalysts play a role in the production of fuels, plastics, fertilizers, batteries, and medicines. Virtually every major industrial chemical process involves at least one catalytic step.

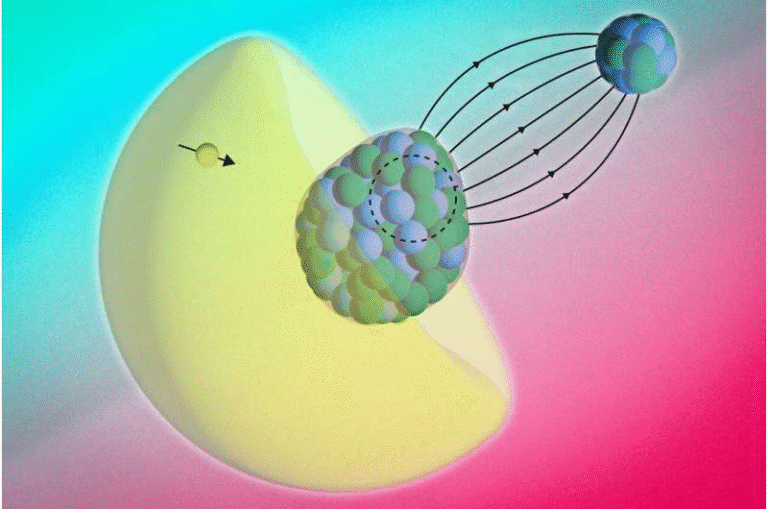

In simple terms, catalysts work by providing a surface where molecules can temporarily bind and react. But what really drives those reactions is electron sharing between the reacting molecule and the catalyst’s surface. When a molecule approaches a catalyst—say, hydrogen meeting a platinum surface—tiny fractions of electrons shift between the two. That small shift changes how stable or unstable the molecule becomes, ultimately determining how easily it reacts.

This idea has been around since the early 1900s, but it has always been theoretical. Until now, there was no direct way to measure how many electrons were being shared at the interface between molecule and catalyst.

The Birth of Isopotential Electron Titration (IET)

Researchers at the Center for Programmable Energy Catalysis, based at the University of Minnesota, wanted to change that. They developed Isopotential Electron Titration (IET), a method that allows scientists to directly measure how much of an electron is transferred between a molecule and a catalyst surface.

The idea behind IET is simple but elegant. Instead of studying catalysts in idealized, simplified environments (as has often been done in the past), IET allows measurements under realistic catalytic conditions—with gases, pressures, and temperatures similar to those used in industry. That’s what makes this method so groundbreaking: it provides an actual, quantitative view of electron sharing in action.

How the IET Technique Works

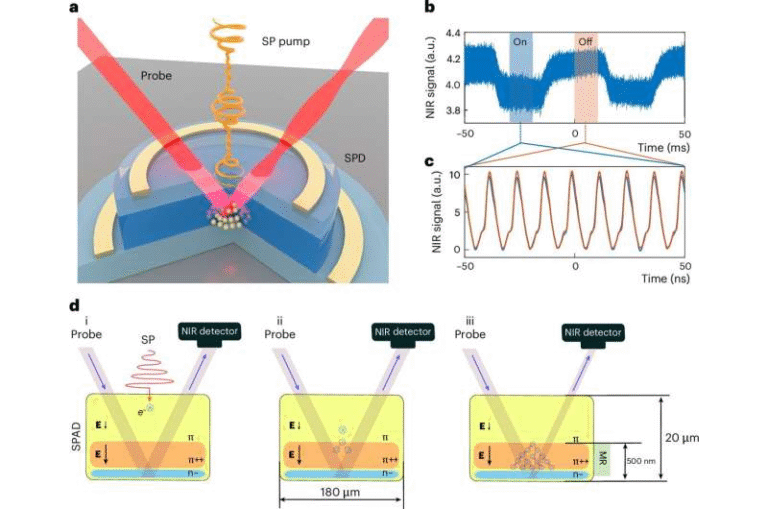

The team built what’s called a catalytic condenser device, which has three main layers:

- A thin platinum (Pt) catalytic surface layer where the chemical reactions happen.

- An insulating layer of hafnium oxide (HfO₂).

- A p-type silicon substrate that acts as the other electrode.

This setup allows both electrodes to be kept at the same electrical potential—hence the term “isopotential.” When gases such as hydrogen (H₂) are introduced, the researchers can precisely control and measure how electrons move between the gas molecules and the platinum surface.

They then cycled the hydrogen pressure between low and high values (ranging from 0.005 to 1 atmosphere) and recorded how much charge flowed through the external circuit as the hydrogen atoms adsorbed (attached) and desorbed (detached) from the platinum. Each adsorption event involves a slight shift in electron density—an electron being fractionally shared or withdrawn. To keep the surface potential constant, the device automatically compensates for these shifts by letting electrons flow through the circuit, and that flow can be measured as a current.

By measuring that compensating charge, the team could determine exactly how much of an electron was exchanged during each binding event.

The Astonishing Numbers

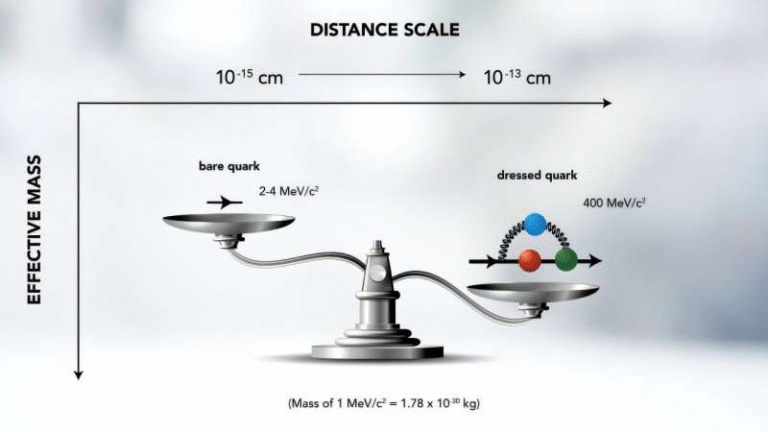

The results were remarkable. When a hydrogen atom binds to a platinum surface, it transfers only about 0.2% of an electron—roughly 0.002 of a single electron’s charge. That’s an unbelievably small quantity, yet it’s precisely this subtle electron sharing that allows platinum to act as such an effective catalyst.

To verify their findings, the team also performed theoretical calculations using Bader charge analysis, a computational method for estimating how electrons are distributed between atoms. The experimental data closely matched the theoretical predictions, confirming the accuracy of the IET technique.

The researchers tested this under a variety of temperatures (125°C to 200°C) and hydrogen pressures (0.005 atm to 1 atm), showing that the method is robust across realistic conditions.

Why This Matters

Measuring such a tiny fraction of an electron may sound like an academic exercise, but it has huge implications. In catalysis, the strength of binding between a molecule and a catalyst’s surface determines how fast and efficiently the reaction proceeds. If the binding is too strong, molecules get stuck and reactions slow down. If it’s too weak, the molecule doesn’t stay long enough to react. The sweet spot depends on how electrons are shared.

Until now, scientists could only infer this from indirect measurements, simulations, or surface spectroscopy under artificial conditions. With IET, they can directly quantify it, opening a new window into the fundamental physics of catalysis.

This gives researchers a new quantitative descriptor—fractional electron transfer—that can be used to screen and design catalysts more intelligently. It could accelerate the development of materials that are cheaper, more selective, and more efficient.

Understanding Why Precious Metals Work So Well

This study also sheds light on why metals like gold, silver, and platinum are so dominant in catalysis. These metals have unique electron configurations that make them particularly good at sharing just the right fraction of their electrons with reacting molecules. They don’t hold onto those electrons too tightly or too loosely—they interact just enough to make reactions happen efficiently.

Now that we can measure exactly how much electron density is transferred, it may be possible to design new non-precious metal catalysts that mimic this behavior. That could significantly reduce costs in industries where platinum or gold catalysts are currently essential, such as fuel cells, refining, and chemical synthesis.

From Fundamental Science to Industrial Impact

The implications extend beyond the lab. The ability to measure and control fractional electron transfer could lead to smarter catalytic processes in major industrial sectors—fuels, chemicals, and materials manufacturing—all of which represent multi-trillion-dollar global industries.

Catalysts are at the heart of technologies that produce cleaner fuels, convert waste gases into useful products, and enable more sustainable chemical manufacturing. If scientists can now tune catalysts at the level of individual electron fractions, it could mean faster reaction rates, lower energy consumption, and less reliance on scarce precious metals.

Moreover, the IET technique could pair with machine learning and nanotechnology, helping scientists explore massive libraries of potential catalyst materials more efficiently. By combining experimental data with computational models, researchers could predict new formulations that might never have been discovered through trial and error alone.

A New Foundation for Catalyst Science

This work represents a new frontier in understanding how catalysts function at the electronic level. By establishing a way to measure fractional electron distribution, scientists now have a direct link between electronic structure and catalytic performance.

The researchers believe that this fundamental insight will drive the next generation of energy and materials technologies, including more efficient hydrogen production, electrochemical fuel synthesis, and environmentally friendly chemical processes.

The research was led by Justin Hopkins, a chemical engineering Ph.D. student at the University of Minnesota, along with Omar Abdelrahman, associate professor at the University of Houston, and Paul Dauenhauer, Distinguished Professor and director of the Center for Programmable Energy Catalysis. The project was funded by the U.S. Department of Energy.

Challenges and Next Steps

While the achievement is groundbreaking, there are still challenges ahead. The IET technique currently works best with relatively simple systems—like hydrogen on platinum—under carefully controlled conditions. Real-world catalysts, however, often involve complex mixtures, multiple reaction intermediates, and harsh industrial environments.

Extending IET to these systems will require further technological innovation. Researchers will need to adapt the method to handle more diverse materials, including metal oxides, alloys, and supported catalysts, and to measure charge transfer in the middle of real chemical reactions, not just in equilibrium adsorption states.

But the path forward is clear: by understanding catalysis at this fundamental level, scientists can begin to design catalysts from first principles rather than by trial and error. This could make the development of cleaner and cheaper chemical processes far more predictable and efficient.

A Quick Primer: What Is Electron Sharing in Chemistry?

In every chemical bond, electrons are shared between atoms. This sharing can range from almost equal (in covalent bonds) to highly uneven (in ionic bonds). Catalysis happens right in between these extremes. When a molecule comes near a catalyst surface, the outer electrons of the metal interact with the molecule’s orbitals, forming a temporary partial bond.

These interactions often involve the transfer of a fraction of an electron—not a whole one. That partial transfer stabilizes the molecule enough to make certain reactions easier, such as breaking hydrogen-hydrogen bonds or forming new carbon-hydrogen bonds. Measuring these fractional transfers lets scientists see exactly how chemical reactions begin at the atomic level.

This is why the new IET method is such a big deal: it quantifies something that was previously just theoretical, turning long-standing chemical intuition into measurable data.

The Broader Picture

Catalysis is the unsung hero of modern civilization. It touches almost every manufactured product: the gasoline in your car, the fertilizers that feed the world, the plastics that make up packaging, and even the medicines that keep us healthy. Yet despite its importance, much about catalysis has remained mysterious at the quantum level.

By finally measuring fractions of an electron, the University of Minnesota and University of Houston team have opened up a new dimension in this field. Their discovery connects the microscopic world of electronic interactions with the macroscopic world of industrial chemistry. It’s a small number—just 0.2% of an electron—but it could have an enormous impact.

Research Reference:

Isopotential Electron Titration: Hydrogen Adsorbate–Metal Charge Transfer (ACS Central Science, 2025)