Edith Cowan University Researchers Pioneer a Smarter, Faster, and Cheaper Way to Extract Essential Oils

A researcher from Edith Cowan University (ECU) has developed a groundbreaking method that could revolutionize essential oil extraction — making it faster, cheaper, and more energy-efficient, while also improving the quality and yield of oils. The technique, known as Instantaneous Controlled Pressure Drop (CID) technology, offers a powerful upgrade over the traditional distillation and solvent-based extraction processes that the essential oils industry has relied on for decades.

Essential oils are the backbone of a vast range of industries — from food flavorings and fragrances to cosmetics, pharmaceuticals, and aromatherapy. Yet despite their popularity, the process of extracting these precious oils from plant materials has always been plagued by the same problems: long extraction times, high energy consumption, and the loss of delicate bioactive compounds due to excessive heat. The new CID technology aims to solve all of that.

The Breakthrough: How CID Technology Works

At the heart of this innovation is a simple but powerful idea — using pressure manipulation to make plant materials give up their essential oils more efficiently. Developed by Ph.D. student Muhammad Hassnain under the supervision of Dr. Muhammad Rizwan Azhar, the technology uses a series of compression–decompression cycles that rapidly heat and then decompress plant matter.

Here’s how it works: the material is first treated with highly saturated steam for a brief moment. Then, the pressure inside the chamber is suddenly dropped, creating a vacuum. This instant pressure release causes rapid vaporization of the volatile compounds — in this case, the essential oils. Each cycle ends with the formation of an emulsion made of water and volatile liquids inside a vacuum tank.

As the pressure drops, the emulsion undergoes abrupt cooling due to sudden volume expansion, which prevents thermal degradation of the sensitive components. This means the process not only extracts more oil, but also preserves its purity and aroma better than traditional heat-intensive methods.

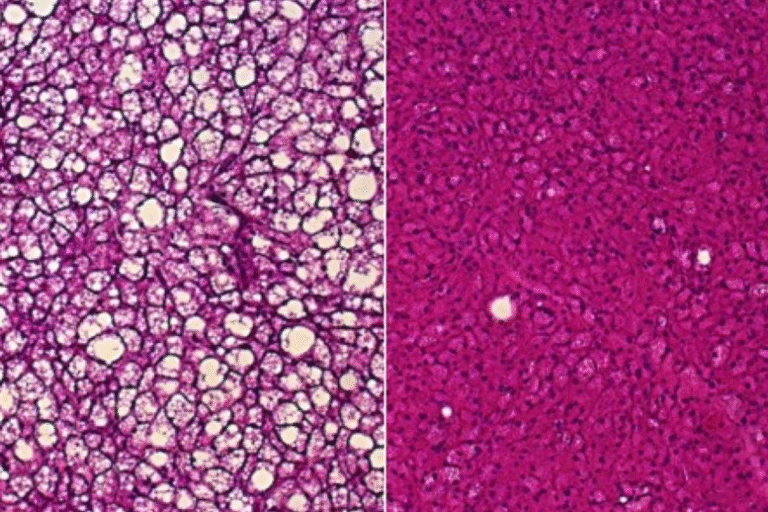

The process can be repeated several times, and with each cycle, the plant material’s internal structure becomes more porous, enhancing heat and mass transfer. The result is higher yield, shorter extraction time, and lower energy use — all key advantages for industries trying to scale production while keeping costs and emissions low.

Why Traditional Methods Fall Short

Traditional methods such as steam distillation, hydrodistillation, and solvent extraction have remained largely unchanged for decades. They typically require hours of heating to coax oils out of plant tissues, consuming large amounts of energy. This extended exposure to heat often damages fragile compounds, leading to lower quality oils that lose some of their fragrance or therapeutic properties.

Solvent extraction, though faster, introduces chemical residues and environmental hazards, while supercritical CO₂ extraction, another advanced method, involves high equipment costs and complex operation.

The new CID approach tackles all these drawbacks head-on. It uses minimal solvents, much less energy, and achieves results in a fraction of the time — all while preserving the integrity of bioactive compounds.

What Makes CID Different

The key to the CID process lies in its thermo-mechanical coupling — combining both heat and mechanical action to improve extraction efficiency. The high-pressure steam softens and heats the plant tissue, while the sudden decompression tears open microscopic pores within the material.

This structural change allows trapped volatile compounds to escape easily. Because the pressure drop happens almost instantaneously, the vapors that form are quickly condensed into liquid, avoiding prolonged heating that typically causes oxidation or loss of fragrance.

The outcome? More oil, less damage, lower cost.

In laboratory and pilot-scale studies, CID-treated materials yielded significantly higher oil volumes compared to conventional steam distillation. The method also cut processing time drastically — a crucial factor for industries handling large quantities of raw botanical material.

The Science Behind It

The phenomenon that makes CID work so efficiently is called autovaporization. When the pressure inside the chamber drops rapidly, the water and volatile compounds within the plant suddenly vaporize. This process draws heat from the material itself, which causes instant cooling — hence preventing the breakdown of heat-sensitive molecules.

This combination of rapid heating and cooling cycles allows better control over extraction conditions, making it possible to fine-tune the process for different plant species and oil types.

Researchers have already identified three commercial variants of the CID process currently available, each applying the same fundamental principle of steam treatment followed by a sudden vacuum drop.

The Focus on Sandalwood Oil

At ECU, the team is now working to optimize CID for extracting sandalwood oil — one of the most valuable and sought-after essential oils in the world. Both Indian sandalwood (Santalum album) and Australian sandalwood (Santalum spicatum) are high-value crops used in perfumery, cosmetics, and traditional medicine.

Sandalwood oil is notoriously difficult to extract because the heartwood contains only a small percentage of oil, and traditional extraction requires long distillation periods — sometimes up to 72 hours. The new CID process promises to cut that time drastically while boosting yield and purity.

Given the global shortage of high-quality sandalwood and the increasing cost of production, this could have major economic benefits for growers and producers, especially in Australia and India.

A Look at Earlier Research on Pressure-Drop Extraction

Although ECU’s work represents the latest and most refined version of CID, the core idea has been explored in other contexts before. Earlier studies used a similar concept called DIC (Décompression Instantanée Contrôlée) — essentially the French version of CID — to extract essential oils from orange peels, cardamom, and other plants.

Those experiments consistently showed dramatic yield improvements and better antioxidant activity compared with conventional methods. For instance, DIC-treated cardamom yielded over 4.4% oil, compared to 2.5% using standard hydrodistillation.

ECU’s contribution builds upon these findings by combining advanced process control and industrial collaboration to move the technology toward commercial viability. The current study consolidates previous research, evaluates existing variants, and proposes optimizations that make CID more adaptable for industrial use.

Why This Matters for Industry and Sustainability

The essential oils market is booming, with rising demand across food, health, and beauty sectors. However, production remains energy-intensive and resource-heavy, often relying on fossil fuels for steam generation.

By making extraction faster and more efficient, CID could help reduce both production costs and environmental impact. Less energy use means lower carbon emissions, and eliminating solvent use helps protect ecosystems and workers from chemical exposure.

Moreover, because the process preserves the natural composition of bioactive compounds, it enhances the oils’ therapeutic and aromatic qualities — a major advantage for companies seeking premium-grade natural ingredients.

The technology also aligns with global trends toward green processing and sustainable manufacturing. As industries move away from solvent-based extractions, methods like CID provide a cleaner, scalable alternative.

Looking Ahead

The research team at ECU is now refining the technology for pilot-scale trials with industry partners. Their goal is to create an economically viable process that can be adopted across the essential oils industry — from small producers to large-scale manufacturers.

If successful, this could mark a significant milestone in process intensification technology, demonstrating how innovative engineering can make natural product extraction both eco-friendly and commercially efficient.

The next steps include detailed techno-economic analyses, energy audits, and comparative yield studies for various plant types. Early results are promising, suggesting that CID may soon become the new gold standard for essential oil extraction.