Scientists Develop a Rapid and Affordable Way to Produce Quantum Nanodiamonds with Breakthrough Potential in Medicine and Technology

A team of scientists led by Dr. Petr Cígler from the Institute of Organic Chemistry and Biochemistry of the Czech Academy of Sciences (IOCB Prague) has unveiled a remarkable new method that could change the landscape of quantum nanodiamond production. Their approach creates light-emitting quantum centers inside nanodiamonds in just minutes, instead of the weeks or even months required by traditional techniques. The findings were recently published in Advanced Functional Materials and are already being hailed as a major step toward industrial-scale manufacturing of high-quality quantum nanodiamonds.

A Process 40 Years Faster

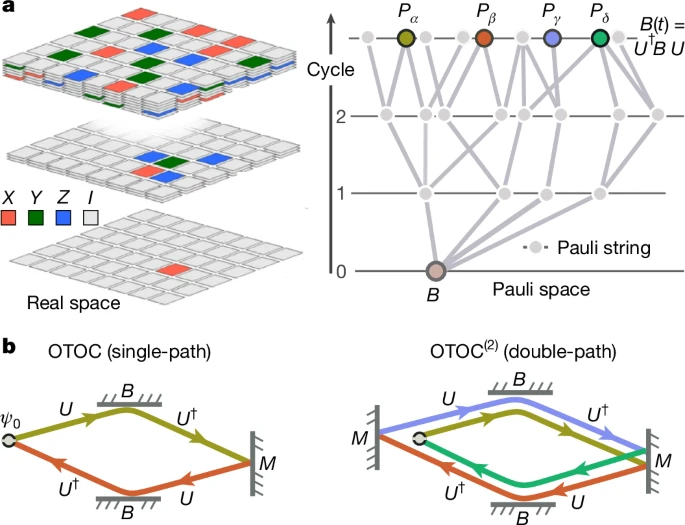

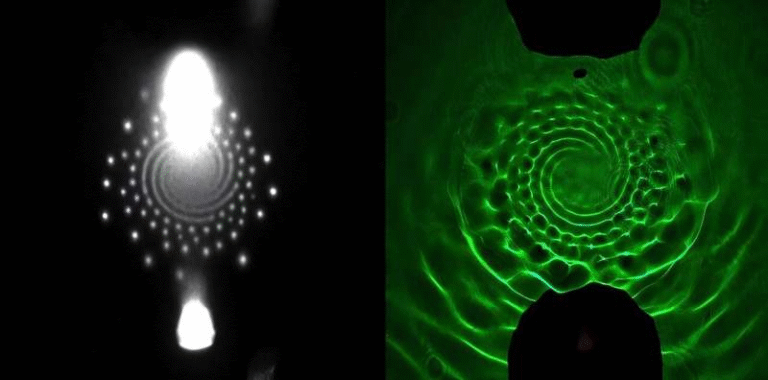

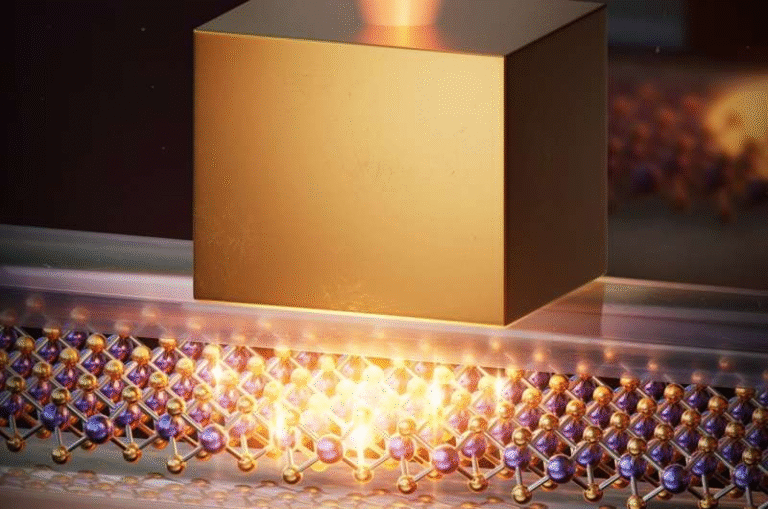

The new technique, called Pressure and Temperature Qubits (PTQ), uses a specialized press to recreate the extreme conditions found deep within Earth’s mantle. Diamond powder is exposed to around 7 gigapascals (GPa) of pressure and temperatures near 1,700 °C for only four minutes. In that time, quantum centers—the features responsible for the diamonds’ glowing and quantum-sensing abilities—form throughout the particles.

To prevent the powder from fusing into larger chunks during the process, the team adds ordinary table salt. When heated, the salt melts and acts as a protective medium around the diamond particles. Afterward, it can be simply washed away with water, leaving behind pure, luminescent nanodiamonds ready for use.

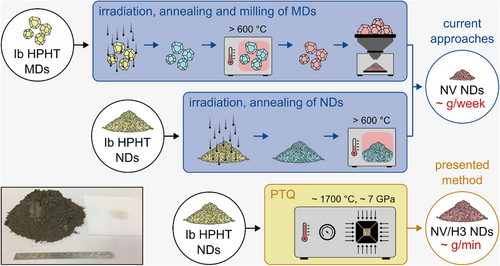

According to the researchers, this method accelerates production over a thousandfold compared with conventional techniques. Using traditional methods, diamond powder must be irradiated with charged particles for weeks, followed by high-temperature annealing to form the desired nitrogen-vacancy (NV) centers. The output is typically less than a gram of usable nanodiamonds. The new PTQ method can produce kilograms in the same timeframe—essentially generating in one week what would otherwise take forty years.

What Makes Quantum Nanodiamonds Special

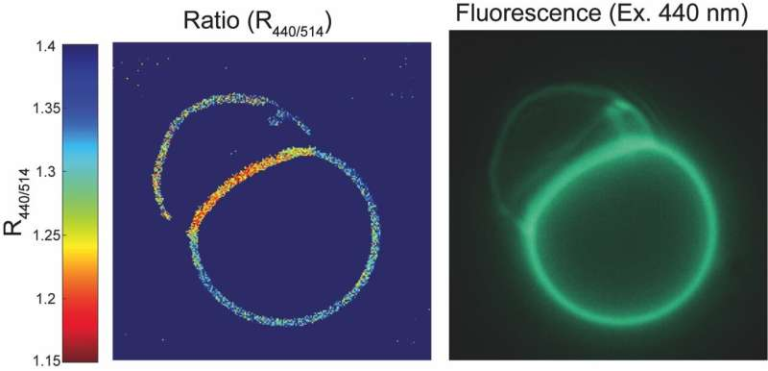

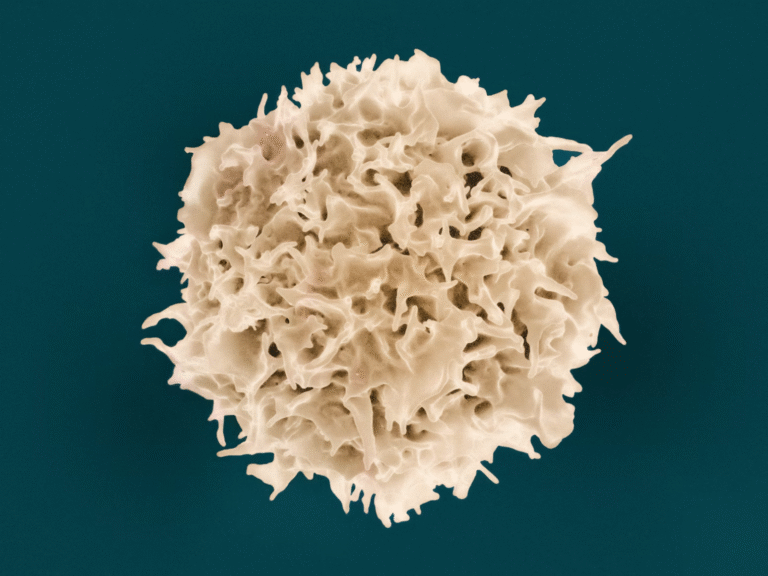

Nanodiamonds are tiny particles, smaller than most viruses, and they are prized for their ability to host nitrogen-vacancy (NV) centers. These are specific defects in the diamond’s atomic structure—where a nitrogen atom replaces a carbon atom adjacent to a missing carbon atom. The result is a fluorescent center that glows when illuminated by light.

This fluorescence is sensitive to magnetic fields, temperature, and charge, making NV centers ideal for quantum sensing. Scientists use them as miniature sensors that can measure magnetic resonance signals, detect molecules, or even track temperature changes inside living cells.

However, one of the biggest hurdles in their use has been production cost and time. Creating NV centers traditionally requires expensive particle accelerators, long processing times, and results in limited yield. This is why the PTQ breakthrough is drawing so much attention—it dramatically simplifies and scales up the process.

Better Optical and Quantum Properties

Beyond the speed advantage, the resulting nanodiamonds are also superior in quality. The PTQ method not only forms red-emitting NV centers, but also green-emitting H3 centers. These multiple color centers expand their potential applications, from quantum computing to bioimaging.

The process also repairs the diamond lattice during the high-pressure deformation stage, improving the stability of the NV centers’ charge state. In simple terms, these new nanodiamonds glow more consistently and respond more precisely in quantum measurements.

Laboratory tests showed significant improvements:

- T₁ relaxation times (a measure of quantum spin stability) reached nearly 1 millisecond, which is exceptional for nanodiamond particles.

- Optical Rabi contrast, an indicator of signal strength and clarity, improved by around five times compared to nanodiamonds made with traditional irradiation.

- The overall magnetic resonance (MR) contrast was also enhanced, meaning these nanodiamonds can serve as more sensitive and accurate quantum sensors.

Scaling Up for Real-World Use

A notable partner in this project is the American company MegaDiamond, which is preparing to launch industrial-scale production of these next-generation nanodiamonds. The goal is to make quantum-grade materials available to research labs, startups, and technology companies around the world at a fraction of the previous cost.

This development could unlock a wide range of applications, including:

- Medical diagnostics, where nanodiamonds can measure temperature or pH inside cells.

- Magnetic resonance nanosensors for studying molecular processes in real time.

- Quantum communication devices that rely on stable light-emitting centers.

- Precision metrology, improving the accuracy of nanoscale measurements.

Because nanodiamonds are non-toxic, chemically stable, and biocompatible, they are especially attractive for biomedical imaging and therapy. Scientists envision a future where they can track drug delivery inside the body or measure tiny magnetic fluctuations in brain tissue—all using these glowing diamonds.

How the PTQ Method Differs

The traditional irradiation method for making NV centers involves bombarding diamond powder with electrons, ions, or neutrons to create vacancies in the crystal lattice. Those vacancies are then made to migrate and pair with nitrogen atoms through high-temperature annealing, often at 800–1000 °C. This entire process can take weeks, requires costly equipment, and frequently damages the crystal structure, degrading the resulting quantum properties.

The PTQ process, on the other hand, relies on plastic deformation under simultaneous high pressure and temperature. This naturally generates the necessary atomic rearrangements and color centers within the lattice—without external irradiation. It’s cleaner, faster, and self-healing. The lattice that forms is less strained, which translates into higher spin coherence and better optical output.

Furthermore, the process uses ordinary diamond powder as the starting material, which makes it economically practical. The use of salt as a temporary buffer medium is a clever and low-cost innovation that prevents particle aggregation and simplifies cleanup.

A Step Toward Quantum Industry

The implications of this breakthrough go beyond academic curiosity. For years, researchers have struggled to produce enough nanodiamonds for quantum technologies to reach commercial viability. Devices that rely on quantum sensing, precision magnetometry, or quantum communication could finally become scalable thanks to this technique.

It’s also a significant leap toward environmentally sustainable production. The PTQ method avoids radiation sources and harsh chemicals, reducing both environmental impact and production hazards.

The research suggests that the process can easily be adapted for large-scale industrial reactors, enabling consistent output of kilogram-scale batches of nanodiamonds with uniform properties. That scalability is what excites both scientists and entrepreneurs, as it paves the way for quantum materials entering real-world markets—from medicine to advanced electronics.

Why Quantum Nanodiamonds Matter

Quantum nanodiamonds are part of a broader field called quantum sensing, which exploits quantum mechanical effects to detect extremely small changes in magnetic or electric fields, temperature, and pressure. Unlike conventional sensors, quantum sensors can reach atomic-level precision.

For example:

- In biomedicine, nanodiamonds can measure temperature variations inside a single cell.

- In materials science, they can detect magnetic fields at the nanoscale, helping engineers study semiconductors and superconductors.

- In navigation and geology, NV-based sensors could provide high-resolution magnetic maps without relying on GPS.

Because NV centers work even at room temperature and under normal lighting, they are easier to use than many other quantum materials, which require cryogenic cooling. This makes them one of the most practical candidates for real-world quantum devices.

The Road Ahead

While the PTQ process still requires further optimization before full commercialization, the results are already groundbreaking. The combination of speed, quality, and scalability positions this technology as a foundation for the next generation of quantum materials.

With institutions like IOCB Prague leading the charge and industry partners such as MegaDiamond preparing for deployment, the coming years may see quantum nanodiamonds move from specialized laboratories to everyday technologies—a transition that could reshape medical diagnostics, computing, and environmental sensing.

Research Reference:

Quantum-Grade Nanodiamonds from a Single-Step, Industrial-Scale Pressure and Temperature Process – Advanced Functional Materials (2025)