Bamboo Tissue Paper Might Not Be the Green Hero We Thought It Was

For years, bamboo tissue paper has been marketed as a cleaner, greener alternative to traditional wood-based paper. Shoppers who care about sustainability often reach for bamboo options thinking they’re making an environmentally responsible choice. But a new study from North Carolina State University suggests that the truth is more complicated — and that bamboo tissue might not be as eco-friendly as many believe.

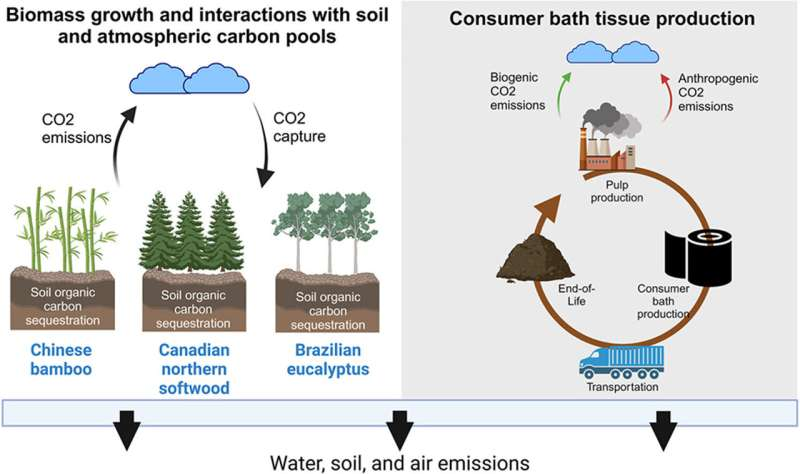

Researchers at NC State carried out a detailed life cycle assessment (LCA) comparing the carbon footprint and environmental impact of bamboo-based tissue made in China with wood-based tissue produced in the United States and Canada. Their findings show that, while bamboo as a raw material isn’t inherently worse than wood, the production process and power sources behind it make all the difference.

The Study Behind the Discovery

The research, published in the journal Cleaner Environmental Systems (2025), is titled “Comparative life cycle assessment of bamboo-containing and wood-based hygiene tissue: Implications of fiber sourcing and conversion technologies.” The study comes from a team at the NC State College of Natural Resources, including lead author Naycari Forfora, a Ph.D. candidate, and co-author Ronalds Gonzalez, an associate professor.

They are part of the Sustainable & Alternative Fibers Initiative (SAFI) — a global coalition of over 30 partners from academia, industry, and government. SAFI’s goal is to improve the sustainability of both conventional and alternative fiber sources by grounding claims in real data rather than marketing buzz.

What the Researchers Compared

The team focused on hygiene tissue products, like toilet and facial tissue, made using two major fiber sources:

- Wood-based pulp from the United States and Canada, including Brazilian bleached eucalyptus kraft (BEK) and Canadian northern bleached softwood kraft (NBSK).

- Bamboo pulp manufactured in China.

The bamboo pulp was analyzed based on the Chinese power grid, which remains heavily reliant on coal. This detail turned out to be a critical factor. To ensure a fair comparison, researchers also simulated scenarios where bamboo tissue was produced in regions with cleaner, lower-carbon energy sources.

The study used standardized LCA methods, considering “cradle-to-gate” and “cradle-to-grave” perspectives — meaning they looked at the emissions and environmental impact from raw material sourcing all the way through production and (in some cases) disposal.

What They Found

The results were clear. Chinese bamboo tissue paper had a carbon footprint of nearly 2,400 kilograms of CO₂ equivalent per ton of tissue produced. In contrast, tissue paper made from wood pulp in the U.S. and Canada had a footprint of around 1,824 kilograms of CO₂ equivalent per ton.

Even when researchers used more energy-intensive production technology — specifically the Creped Through Air Drying (CTAD) process — the pattern held. Wood-based tissue emitted about 2,531 kg CO₂ per ton, while bamboo-based tissue made in China emitted around 2,739 kg CO₂ per ton.

In addition to greenhouse gases, the study looked at other environmental categories like smog formation, respiratory health impacts, and ecotoxicity. Bamboo tissue again performed worse than its North American counterpart across these metrics.

However, when the team modeled bamboo production using cleaner electricity, such as grids powered by renewables or low-carbon energy sources, the environmental differences largely disappeared. That finding highlights a key takeaway: the environmental impact of tissue paper depends more on manufacturing technology and energy mix than on the type of fiber used.

Why China’s Energy Mix Matters

The study’s authors emphasize that China’s coal-dependent electricity grid is a major reason bamboo tissue production scores worse in environmental metrics. The country generates the majority of its power from coal-fired plants, which emit large amounts of CO₂ and other pollutants.

In contrast, North American manufacturing facilities often rely on cleaner, mixed energy grids — including natural gas, hydroelectric, and renewables — significantly reducing emissions per unit of production.

So, while bamboo itself is a fast-growing, renewable crop, the benefit of using it is undercut if the conversion process depends heavily on fossil fuels. The takeaway is that sustainability isn’t just about the material — it’s about the entire production system behind it.

How Tissue Paper Is Made

To understand why energy plays such a big role, it helps to know how tissue paper is produced. Whether made from wood pulp or bamboo pulp, the process involves several high-energy stages:

- Pulping, where fibers are separated and cleaned.

- Bleaching, which uses chemicals to whiten the paper.

- Drying and creping, which require heat and air — processes that consume massive amounts of energy.

When these stages are powered by coal-heavy electricity, even an otherwise renewable raw material like bamboo can end up with a high carbon footprint.

A Closer Look at Bamboo’s Reputation

Bamboo has long been promoted as an eco-friendly superstar because it grows quickly and doesn’t require replanting after harvest. It’s also often described as a “tree-free” alternative, implying that it helps preserve forests.

However, as co-author Ronalds Gonzalez points out, bamboo is cultivated much like plantation trees — it’s grown, harvested, and processed using the same industrial methods. And when it comes to environmental impact, the plant’s rapid growth doesn’t automatically translate to lower emissions if the production infrastructure is carbon-intensive.

This challenges the simple narrative that bamboo products are inherently green. The reality is that bamboo’s benefits depend heavily on how and where it’s processed.

The Bigger Picture for Sustainable Fibers

The findings don’t mean bamboo tissue should be dismissed entirely. Instead, they call for a more nuanced approach to sustainability. Forfora and her team found that technological improvements and cleaner energy sources make a much bigger difference than swapping fiber types.

This means the focus for reducing emissions in the paper industry should be on modernizing production technologies, decarbonizing power grids, and optimizing logistics — not just switching raw materials.

Organizations like SAFI are working to ensure that claims about “sustainable” or “green” fibers are based on measurable life cycle data. Their research aims to help both manufacturers and consumers understand what truly reduces environmental harm.

What Consumers Should Know

If you’re an environmentally conscious shopper, this study offers an important reminder: labels can be misleading. Bamboo tissue products may sound sustainable, but unless they come from facilities powered by renewable energy and use efficient manufacturing processes, they might not be the greener choice.

Consumers can look for certifications or disclosures that mention energy sources, carbon offsets, or verified LCAs. While it’s not always easy to find this information on packaging, awareness is growing — and consumer demand for transparency can push companies to improve their processes.

Why Studies Like This Matter

Life cycle assessments like this one are vital for cutting through marketing hype and focusing on what really makes a product sustainable. Many “green” products on the market focus on a single appealing attribute — such as being “tree-free” — while ignoring the broader context of production and energy use.

By quantifying emissions, pollution, and other environmental effects, researchers can give companies concrete data to improve manufacturing, supply chains, and policy decisions.

Final Thoughts

The NC State study reminds us that sustainability is a systems problem. Bamboo may be a fast-growing plant, but if it’s processed in a coal-powered factory, the end result isn’t much better for the planet than conventional tissue. Cleaner energy, smarter technologies, and transparent data matter far more than the type of plant fiber on the packaging.

If bamboo tissue is to live up to its eco-friendly reputation, the industry needs to shift production to regions with cleaner electricity and adopt modern, energy-efficient processes. Until then, the greener choice might still come from a well-managed, sustainably sourced wood pulp mill powered by renewable energy.