A New Microneedle Sensor Can Tell How Fresh Your Fish Is in Under Two Minutes

Checking whether fish is fresh has always been a bit of a guessing game. People look at the eyes, inspect the gills, press the flesh, or rely on smell. While these methods can work to some extent, they are subjective and often fail to detect spoilage in its earliest stages. Now, researchers have developed a simple electronic sensor that can determine fish freshness quickly, accurately, and objectively, and it does so in less than two minutes.

The new technology was reported in the scientific journal ACS Sensors and represents a promising step toward real-time food quality monitoring, especially for seafood.

Why Fish Freshness Is Hard to Measure

Fish begins to deteriorate almost immediately after it dies. However, the visible signs most people rely on—such as cloudy eyes, bruised gills, or strong odors—may not appear for hours or even days. By the time those clues become obvious, the fish may already be unsafe or unpleasant to eat.

From a scientific perspective, spoilage begins at the molecular level. As soon as a fish dies, nucleic acids and other cellular components start breaking down, producing chemical compounds associated with decomposition. One of the most important of these compounds is hypoxanthine, commonly abbreviated as HX.

Researchers consider HX to be a reliable freshness indicator because it forms very early in the spoilage process and steadily increases over time. Unlike smell or appearance, HX levels provide a quantifiable and objective measure of how fresh a fish actually is.

The Problem With Current Testing Methods

While HX is widely accepted as a marker of freshness, measuring it is not easy outside a laboratory. Current methods typically involve time-consuming sample preparation, specialized instruments, and trained personnel. This makes routine HX testing impractical for fish markets, restaurants, distributors, or consumers.

Because of these limitations, most seafood quality checks still rely on visual inspection and experience, leaving room for error and inconsistency. This gap between scientific accuracy and real-world practicality is exactly what the new sensor aims to address.

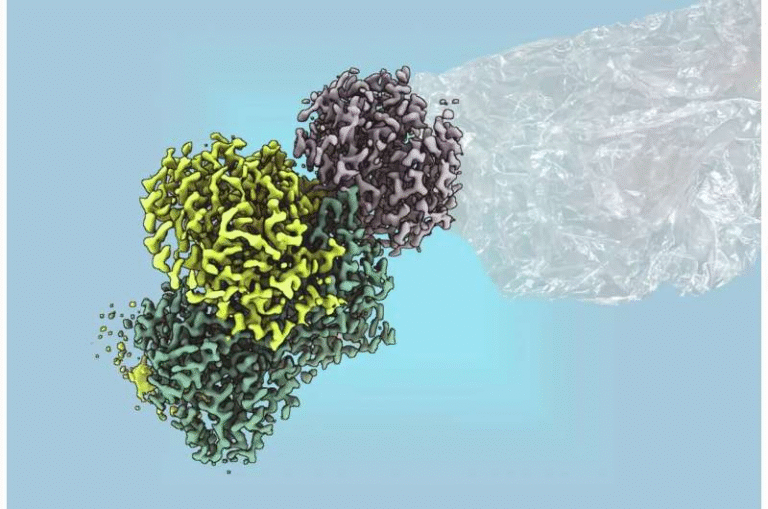

Introducing the Microneedle-Based Freshness Sensor

To make HX monitoring faster and more accessible, researchers Nicolas Voelcker, Azadeh Nilghaz, Muamer Dervisevic, and their colleagues developed a microneedle-based electronic sensor designed specifically for fish freshness testing.

Microneedles are typically associated with drug delivery systems or skincare products, but in this case, they play a different role. The microneedles help the sensor make direct contact with the fish tissue, dramatically improving sensitivity and accuracy.

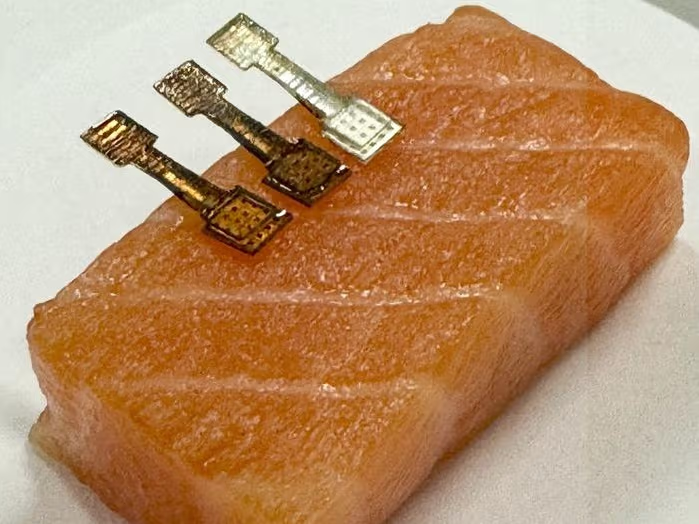

The device features a four-by-four array of microneedles, creating a compact 16-needle surface. Each microneedle is coated with specialized gold nanoparticles and an enzyme that breaks down hypoxanthine. This combination allows the sensor to detect extremely small amounts of HX quickly and reliably.

How the Sensor Works

Using the sensor is straightforward. The microneedle array is gently pressed into the surface of a fish fillet or steak. The needles anchor the device in place and allow the enzyme coating to interact directly with the fish tissue.

When hypoxanthine is present, the enzyme breaks it down, triggering a change in electrical potential within the fish. The sensor measures this electrical change and translates it into a quantitative freshness reading.

The entire process takes around 100 seconds, meaning results are available in under two minutes. This speed makes the sensor suitable for real-time testing, something that has not been practical with conventional laboratory methods.

Testing the Sensor on Real Fish

To validate the sensor’s performance, the research team conducted experiments using salmon steaks. The fish was cut into small pieces and left to spoil at room temperature for up to 48 hours, simulating real-world conditions where freshness declines over time.

The sensor successfully detected hypoxanthine concentrations as low as less than 500 parts per billion. According to established standards, this level corresponds to fish that is considered very fresh.

Importantly, the sensor’s sensitivity was found to be comparable to that of commercially available laboratory-based testing kits. In other words, the portable prototype delivered results on par with much larger and more complex lab equipment.

Why This Matters for Food Safety

Being able to measure fish freshness accurately and quickly has significant implications for food safety and quality control. Spoiled seafood can lead to foodborne illnesses, economic losses, and unnecessary food waste.

A portable sensor like this could be used by fishers, distributors, wholesalers, retailers, and restaurants to assess freshness at multiple points along the supply chain. Instead of relying on subjective judgment, users could make decisions based on objective chemical data.

For consumers, such technology could eventually mean greater transparency and confidence in the seafood they buy.

The Bigger Picture of Freshness Monitoring

This research also highlights a broader trend in food science: the move toward real-time, on-site monitoring rather than centralized laboratory testing. As sensors become smaller, cheaper, and more sensitive, they open the door to smarter quality control systems across the food industry.

Hypoxanthine itself is not unique to fish. Similar biochemical markers are used to assess freshness in other meats and perishable foods. This means the underlying technology could potentially be adapted for other food products in the future.

What Still Needs to Be Done

While the results are promising, the sensor is still in the prototype stage. Further development is needed before it can be widely deployed as a commercial food safety tool. Researchers will need to refine durability, scalability, and ease of use before the sensor is ready for everyday applications.

That said, the study clearly demonstrates the potential of microneedle-based biosensors for food-quality monitoring and shows that laboratory-level accuracy is possible in a compact, portable format.

A Step Toward Smarter Food Quality Checks

This new sensor does not replace common sense or traditional inspection methods, but it adds a powerful new option to the toolbox. By focusing on chemical indicators instead of appearances, it provides a more reliable way to assess freshness when it matters most.

As food safety standards continue to evolve, innovations like this could help ensure that what ends up on our plates is not just appealing, but genuinely fresh and safe to eat.

Research Paper:

Enhancing Food Safety with Microneedle-Based Biosensors: Real-Time Monitoring of Fish Freshness, ACS Sensors (2025)

https://doi.org/10.1021/acssensors.5c01637