Algae-Based Asphalt Binder Could Make Roads Stronger and Greener in Cold Climates

Snow, ice, and freezing temperatures are some of the biggest enemies of modern roads. Every winter, pavements across colder regions crack, heave, and develop potholes as temperatures plunge and then rise again. These damages are not only expensive to repair but also dangerous for drivers and pedestrians. Now, new research suggests that an unexpected green ingredient — algae — could help make asphalt roads stronger, more flexible, and far more sustainable in cold climates.

Researchers reporting their findings in ACS Sustainable Chemistry & Engineering have developed an algae-derived asphalt binder that outperforms traditional petroleum-based binders at subzero temperatures. The results point to a future where roads last longer, cost less to maintain, and generate significantly lower carbon emissions.

Why Traditional Asphalt Struggles in Cold Weather

To understand why this research matters, it helps to know how asphalt works. Asphalt pavement is made from aggregates like sand and crushed stone, all held together by a sticky binder called bitumen. Bitumen is a thick, black material derived from crude oil, and it plays a crucial role in allowing pavement to flex under traffic and temperature changes.

However, bitumen has a major weakness. When temperatures drop rapidly below freezing, the binder becomes brittle. Instead of flexing, it cracks. Over repeated freeze–thaw cycles, these cracks expand, moisture seeps in, and the pavement begins to fail. This leads to frost heaves, surface cracking, and potholes, which are especially common in colder regions.

Engineers have long searched for ways to improve asphalt’s flexibility and durability in winter conditions without dramatically increasing costs or environmental impact.

How Algae Entered the Picture

The research team, led by Elham Fini, explored whether oils extracted from algae could be used to create a more resilient asphalt binder. Algae are already known for their versatility — they can produce oils, fuels, and specialty chemicals — and they can be grown sustainably using limited land and resources.

Earlier work by the same team had already shown that algae oil can be converted into a bitumen-like material that performs well at low temperatures. Building on those findings, the researchers took a deeper and more systematic approach to identify which algae types worked best and how they behaved under realistic conditions.

Testing Oils From Four Algae Species

In the latest study, the researchers examined oils from four different algae species. Using computer simulations and laboratory experiments, they evaluated how well each oil could:

- Mimic the properties of conventional bitumen

- Blend with asphalt aggregates

- Maintain flexibility at freezing and subzero temperatures

- Resist permanent deformation under traffic loads

Among the four species tested, one stood out clearly. Oil derived from the freshwater green microalgae Haematococcus pluvialis showed the most promising performance across multiple criteria.

Why Haematococcus Pluvialis Performed Best

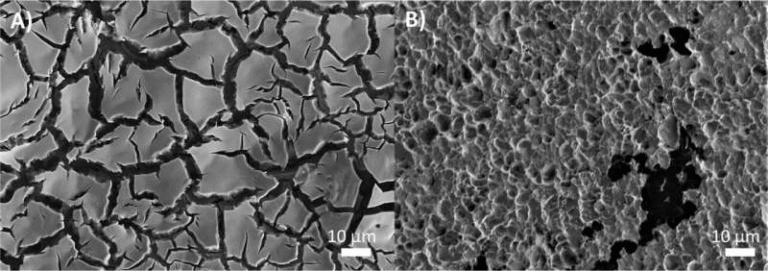

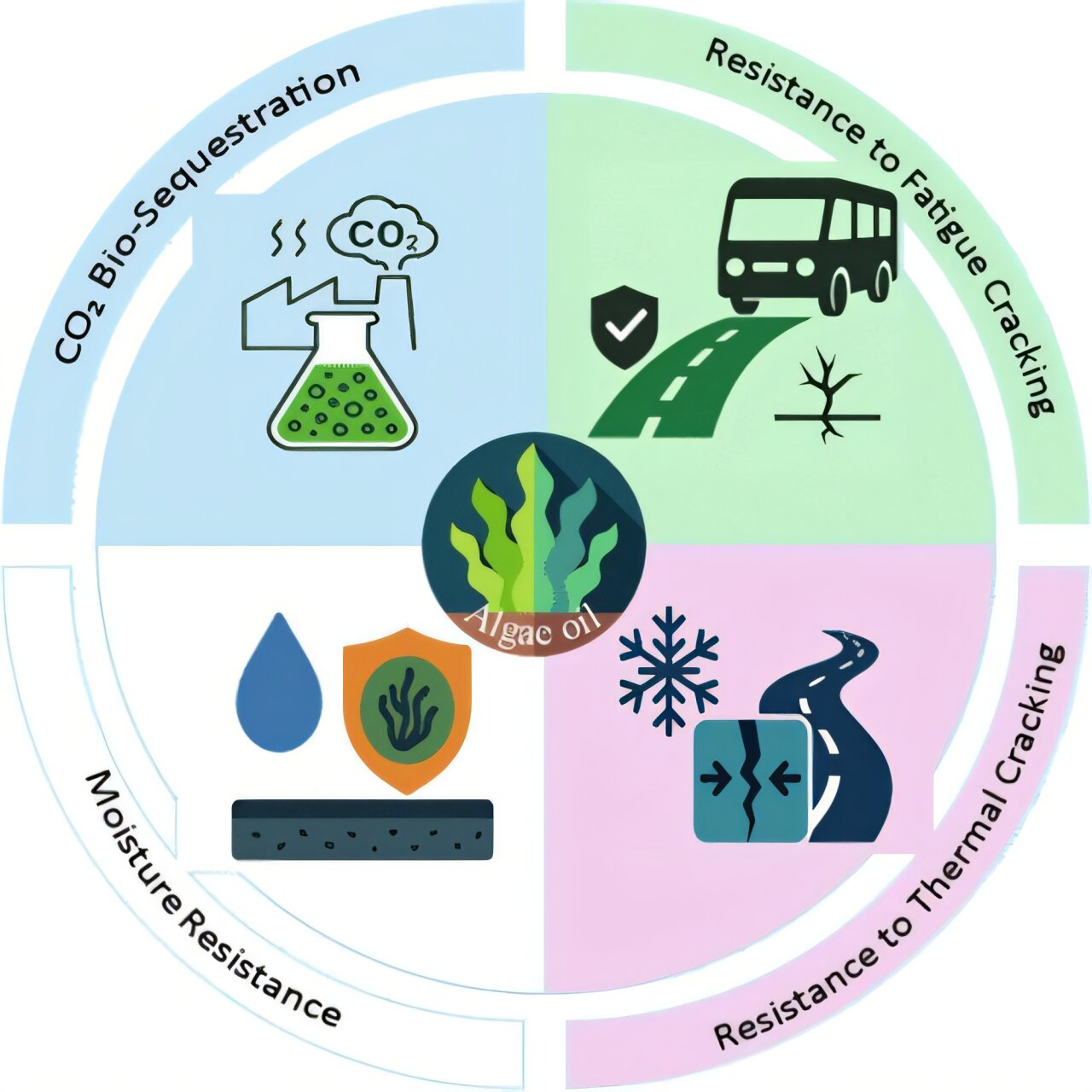

Asphalt samples made with H. pluvialis algae oil demonstrated strong resistance to permanent deformation, meaning the pavement was better able to recover its shape after being stressed by traffic. The algae-based binder also improved resistance to moisture-induced damage, a critical factor in freeze–thaw environments where water infiltration accelerates cracking.

In laboratory tests designed to simulate real-world traffic and repeated freezing cycles, asphalt containing the algae binder showed up to a 70% improvement in deformation recovery compared to pavement made with a conventional petroleum-based binder. In practical terms, this means the algae-modified asphalt was far better at bouncing back instead of cracking or permanently deforming.

Environmental Benefits Go Beyond Performance

The advantages of algae-based asphalt are not limited to durability. The environmental implications are equally significant.

The researchers estimate that replacing just 1% of petroleum-based binder with algae-derived binder could reduce the net carbon emissions of asphalt by about 4.5%. This is a meaningful reduction for an industry that relies heavily on fossil fuel materials.

At higher substitution levels, the impact becomes even more striking. The study suggests that at around 22% algae-based binder, asphalt pavement could become carbon neutral. With further optimization, it could potentially move into carbon-negative territory, depending on how the algae are grown and processed.

Why Algae Are a Sustainable Choice

Algae offer several sustainability advantages over traditional petroleum-based materials:

- They absorb carbon dioxide as they grow

- They can be cultivated in wastewater or non-arable land

- They grow rapidly compared to traditional crops

- They do not compete directly with food production

These traits make algae especially attractive for large-scale industrial applications like road construction, where material volumes are enormous and environmental impacts add up quickly.

Self-Healing and Moisture Resistance

Beyond flexibility and emissions, the algae-based binder also showed improvements in self-healing behavior. Asphalt naturally has some ability to heal tiny cracks over time, especially when exposed to heat. The algae binder enhanced this effect, allowing microcracks to close more effectively before they grew into serious damage.

Improved moisture resistance was another key benefit. Water infiltration is one of the main causes of pavement failure in cold regions, and reducing moisture damage could significantly extend pavement lifespan.

Compatibility With Existing Infrastructure

One of the most practical aspects of this research is that the algae-based binder is designed to be compatible with existing asphalt production methods. The binder mixes well with conventional aggregates and does not require a complete overhaul of current road-building equipment or techniques.

This means the technology could potentially be adopted without massive infrastructure investments, making it more appealing to transportation agencies and contractors.

Challenges and Future Outlook

While the results are promising, challenges remain. Producing algae oil at large scales has historically been more expensive than refining petroleum-based binders. However, continued advances in algae cultivation, processing efficiency, and the potential for long-term maintenance savings could improve cost competitiveness over time.

The researchers emphasize that this work is a step toward high-performance, cost-effective, and environmentally responsive pavement infrastructure, particularly for regions that experience harsh winters.

What This Means for the Future of Roads

If algae-based binders can be scaled successfully, the implications are far-reaching. Roads could last longer, require fewer repairs, and contribute less to climate change. Municipalities could save money on maintenance while improving safety for drivers and pedestrians.

Most importantly, this research highlights how bio-based materials can play a meaningful role in transforming even the most traditional industries, including road construction.

Research Reference:

https://pubs.acs.org/doi/10.1021/acssuschemeng.5c03860