Georgia Tech’s New Bio-Based Film Shows Plastic-Like Protection Against Moisture and Oxygen

Researchers at the Georgia Institute of Technology have created a renewable, biodegradable film that performs as well as — and in some cases even better than — common plastic packaging when it comes to blocking moisture and oxygen. This development comes at a time when the world is grappling with the environmental burden of plastic waste, which often sits in landfills or pollutes oceans for centuries before breaking down. The new film aims to offer a high-performance alternative that naturally returns to the environment.

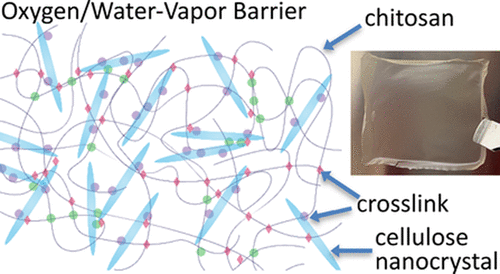

Developed by a team led by Carson Meredith, a Georgia Tech professor and executive director of the Renewable Bioproducts Institute, the material relies entirely on ingredients already found abundantly in nature. The film is composed of cellulose (the structural component in plants), chitosan (a substance obtained from crustacean shell waste or mushrooms), and citric acid (commonly found in citrus fruits). All three components are renewable, biodegradable, and widely available.

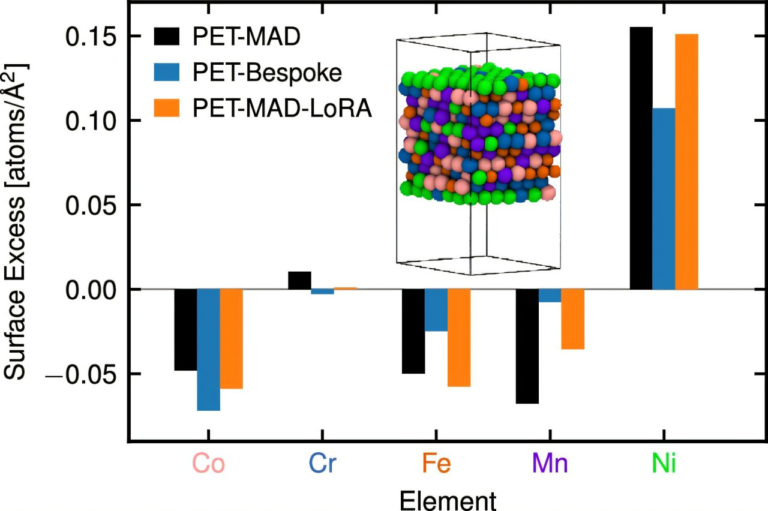

The research team has been working for over a decade to find viable natural replacements for plastic packaging, with a special focus on films that can keep out oxygen and water vapor. This is a critical challenge. Foods, pharmaceuticals, and electronic components all need packaging that stops moisture and oxygen from entering. For years, petroleum-based plastics like polyethylene terephthalate (PET) and ethylene vinyl alcohol (EVOH) have excelled at this job. Bio-based films, however, have struggled — especially in humid environments, where natural polymers tend to swell, soften, or lose their protective qualities.

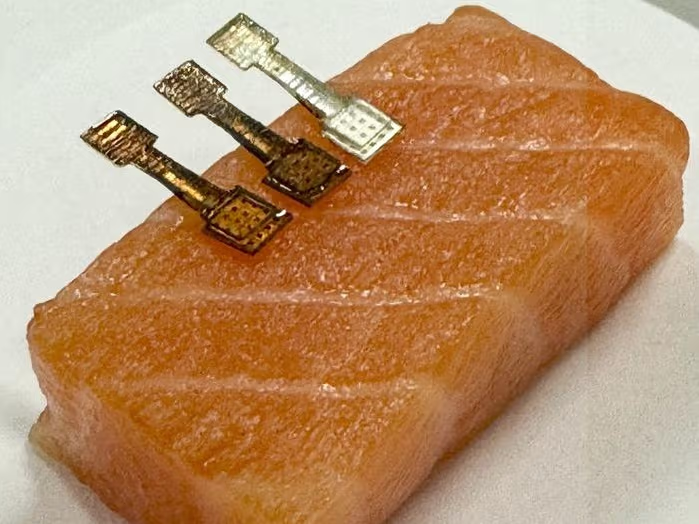

To solve this, the Georgia Tech team discovered that blending cellulose, chitosan, and citric acid and then cross-linking them — followed by a controlled heat treatment — creates a structured, dense film. This molecular organization is what makes the film unique. It resists the typical humidity-induced swelling that weakens most biopolymer films, allowing it to maintain its protective barrier even in challenging climates.

In fact, the new film performed exceptionally well at 80% relative humidity, a level often used to simulate tropical or hot-weather conditions. At this humidity, the material showed extremely low oxygen permeability and reduced water vapor transmission. These measurements matched or surpassed those of widely used plastics such as PET and EVOH, which are considered industry standards for high-barrier packaging.

This structure is made possible by three key components working together:

- A carbohydrate polymer (cellulose) forms the backbone and provides rigidity.

- A plasticizer helps maintain flexibility so the film doesn’t become overly brittle.

- A water-repelling additive helps push away moisture and reinforces the film’s stability.

When cast into thin films, these ingredients self-assemble in a highly ordered network, producing a strong barrier that resists the usual humidity-related performance drop that plagues biopolymers.

While this is a major step forward, the researchers acknowledge that the technology is still in development. One of the biggest challenges ahead is scaling up. Large-scale packaging production requires films that can be coated, dried, and processed quickly. Some early indications suggest that the film may be slow to dry or difficult to produce in thicker formats. For industrial operations that run at high speeds, this could be a bottleneck.

Because of this, the researchers believe the most realistic starting point may be using the new material as a coating applied to another substrate — such as paper or another biodegradable material — rather than producing standalone plastic-like sheets. Coatings require much thinner layers and can be applied using existing manufacturing equipment, which makes commercialization more feasible.

Despite this, the new film demonstrates real potential as a sustainable replacement for many traditional plastic packaging formats. The fact that it’s renewable, biodegradable, and made from waste-derived or plant-based inputs gives it a strong environmental advantage. In a global landscape where consumers and industries are increasingly looking for eco-friendly packaging, this type of innovation could be transformative.

Another interesting aspect of this research is the collaborative nature of the project. Lead author Yang Lu, formerly a postdoctoral researcher at Georgia Tech, helped develop the film’s humidity-resistant structure. The project also included contributions from Natalie Stingelin, a professor in Georgia Tech’s School of Materials Science and Engineering. The work received support from the Renewable Bioproducts Institute, Mars Inc., and a U.S. Department of Defense fellowship, which highlights how widely applicable the technology could be.

Beyond the immediate findings, this research connects to a much larger global push to replace petroleum-based plastics with renewable alternatives. While many biodegradable films already exist, they often fail under real-world conditions — especially in heat and humidity. The Georgia Tech film directly addresses that weakness. And because its ingredients are biodegradable, the film would naturally break down in the environment rather than persisting for centuries.

Still, it’s important to consider that replacing traditional plastics entirely will require more than just matching barrier performance. Packaging materials must also be durable, affordable, and compatible with existing equipment. They have to seal well, resist tearing, withstand folding and handling, and deliver consistent quality. Early studies suggest the Georgia Tech film is mechanically robust, but some versions may be more brittle than petroleum-based films, which could pose a challenge for certain applications.

Despite these hurdles, the research sits at the intersection of sustainability, materials science, and circular economy innovation. If the technology scales effectively, industries that require high-performance packaging — from snack foods to medical devices — could eventually transition away from petroleum plastics toward materials that come from nature and safely return to nature.

Additional Context: Why Moisture and Oxygen Barriers Matter

To understand why this film is so promising, it’s helpful to know why moisture and oxygen barriers are so important in packaging:

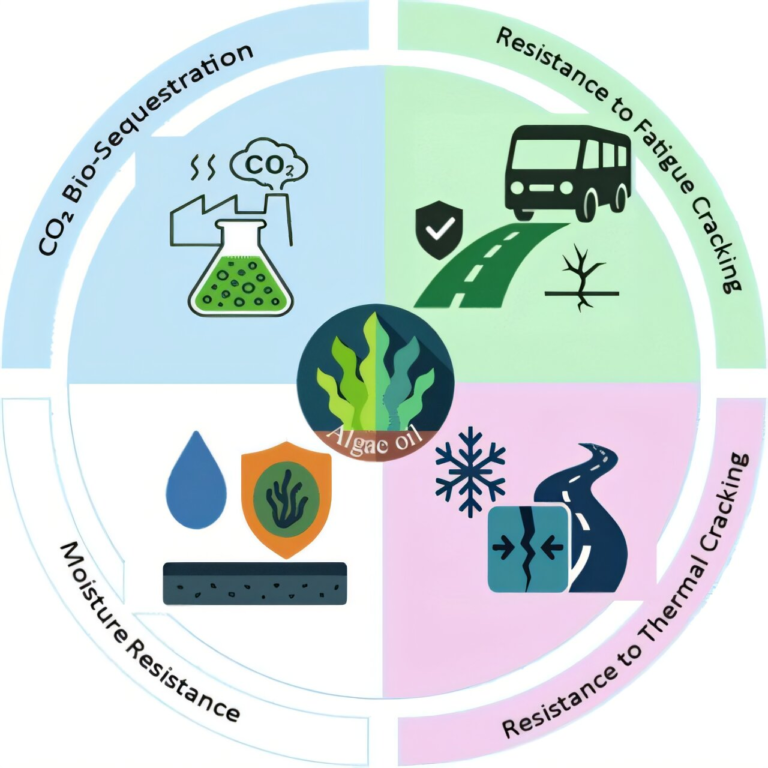

Moisture barriers prevent water vapor from entering or escaping a package. This is crucial for foods like chips, crackers, powdered products, and freeze-dried items. Moisture is also a risk for electronics, certain medications, and metal components that can corrode.

Oxygen barriers prevent oxidation, which causes spoilage, loss of flavor, nutrient degradation, corrosion, and chemical instability. Products like coffee, nuts, oils, and pharmaceuticals all need strong oxygen barriers.

Most biodegradable films struggle to compete with conventional plastics in these two areas — especially under humid conditions. That’s why this research stands out: the new film’s performance remains strong even in environments that mimic tropical humidity.

Additional Context: What Are Cellulose and Chitosan?

Since the film is built from natural materials, it’s worth briefly understanding them:

Cellulose

Cellulose is the most abundant organic polymer on Earth. It forms the cell walls of plants and is used in paper, textiles, and biodegradable materials. It is strong, renewable, and stable, making it an excellent structural polymer for sustainable packaging.

Chitosan

Chitosan comes from chitin, the substance found in the shells of crabs, shrimp, and other crustaceans — as well as fungi. Because seafood processing generates large amounts of shell waste, chitosan is widely available. It is biodegradable, naturally antimicrobial, and often used in medicine, agriculture, and water purification.

Together with citric acid, these materials create a renewable, eco-friendly mixture capable of competing with plastic.