Magnetically Reconfigurable Ribbons Let Scientists Program Liquids on Demand

Researchers have introduced a surprisingly simple yet powerful way to control how liquids behave, using magnetically reconfigurable ribbons that can switch shape on command and hold their new form without consuming power. This work, published in the journal Device, comes from the team of Xueju Sophie Wang at the University of Connecticut, in collaboration with groups from the University of Edinburgh and Syracuse University. The study presents a full system where shape-shifting soft materials function almost like mechanical memory units, enabling intelligent liquid routing, droplet control, and programmable surfaces.

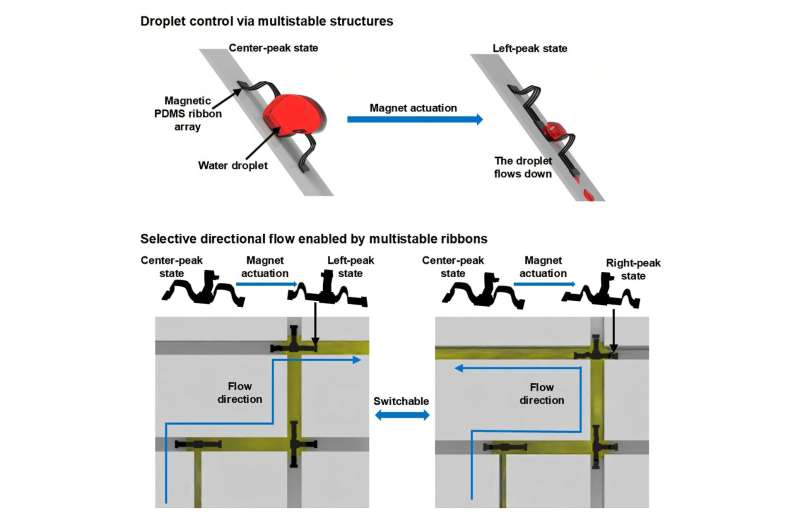

At the center of the research are thin ribbons made from magnetic polydimethylsiloxane (PDMS)—a soft, silicone-based material embedded with magnetic particles. These ribbons are engineered through compressive buckling so that each one naturally holds three distinct stable shapes. With just a brief magnetic signal, a ribbon can be switched between these shapes. Because each configuration is mechanically stable, the ribbon stays in that state even after the magnetic field is removed. This property is essentially a built-in memory mechanism, which is unusual for soft materials and extremely useful in fluid-handling systems where continuous power is often a limitation.

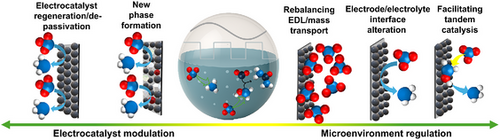

The team demonstrated three major capabilities: redirecting liquids, programming droplet behavior, and changing surface properties on demand. In the first demonstration, the researchers built a switchable fluid junction inside a two-dimensional microfluidic channel. By toggling a ribbon between its stable configurations, the device could steer a flowing liquid toward different outlet paths—essentially acting as a valve that needs no sustained energy. Because the structure remains locked in place after switching, the chosen flow route persists, making it ideal for portable or battery-powered microfluidic systems.

Next, the team extended the concept to surface design. By arranging multiple ribbons into a programmable array, they created a dynamic surface where each ribbon’s shape contributes to the overall geometry. Switching individual ribbons changes the surface’s critical angles, which are the precise conditions determining whether droplets will stick to the surface or slide off. This type of control is important for tasks such as holding a droplet in one spot, releasing it at a chosen moment, or guiding it on a predefined path.

In a test using a 2×3 ribbon array, the authors showed that each droplet’s movement could be managed with fine precision. A droplet could be held securely by setting the ribbons into one combination of shapes, nudged into a new direction by switching selected ribbons, or released entirely by adjusting the topology. This creates a type of pixel-level liquid control, which could reshape the way lab-on-a-chip devices handle chemical processing, biological assays, and analytical operations.

To support the experimental work, researchers from the University of Edinburgh and Syracuse University conducted detailed theoretical and numerical modeling. They used meso-scale simulations that incorporate coupled electrocapillary effects, enabling them to map how the ribbons’ geometry influences droplet behavior. These models help predict what will happen when the ribbons are arranged in larger arrays, and they offer guidelines for designing future devices with more complex behavior. Because droplet manipulation depends heavily on the balance between surface structure, capillary forces, and fluid interactions, having a predictive model is essential for scaling this technology.

One of the most promising aspects of this system is its energy efficiency. Many microfluidic devices rely on a continuous supply of power to keep valves open, maintain flow directions, or operate pumps. Here, the ribbons require power only at the moment of switching. Once the desired configuration is set, no additional energy is needed. This could dramatically reduce energy costs—and device complexity—in applications ranging from field-portable testing kits to automated chemical reactors.

This research also hints at broader possibilities. Soft materials capable of mechanical memory could enable adaptive materials, programmable soft robotics, or smart surfaces that respond to their environment. For example, surfaces might dynamically adjust their textures to control condensation, friction, or adhesion. In the future, arrays of multistable ribbons could function like mechanical logic elements for fluid processing, where instructions are encoded directly into the material rather than an electronic controller.

Understanding Magnetic PDMS

Because magnetic PDMS is at the heart of this system, it is useful to understand why it behaves the way it does. PDMS itself is a flexible silicone that is commonly used in biomedical devices, microfluidics, and soft robotics because it is transparent, biocompatible, and easy to mold. By embedding magnetic particles into it, researchers create a material that remains soft but responds predictably to magnetic fields. This blend of softness and controllability is extremely valuable when designing components that must deform repeatedly without damage.

Magnetic PDMS composites can be tuned by adjusting particle concentration, particle type, or curing conditions. Doing so changes the stiffness, magnetization strength, and responsiveness of the final material. In the case of the ribbons in this study, engineers carefully shaped the PDMS through compressive buckling, a process where the material is controlled into a predefined geometry that naturally holds multiple stable positions.

Why Multistability Matters

A multistable structure is one that can rest in different stable configurations without energy input. Familiar examples include snap bracelets or some folding mechanisms in robotics. In fluid handling, multistability is useful because it eliminates the need for constant actuation. If a device needs to route liquid in a certain direction for a long time, the material simply stays in its chosen configuration. This eliminates pumps, motors, or electromagnets that would normally be required to maintain control.

The ribbons in this study offer three stable states, making them more versatile than typical bistable structures. Having three options enables more complex patterning, more routing pathways, and more nuanced droplet manipulation.

Broader Applications in Microfluidics

Microfluidics is a field that benefits heavily from precise and reliable control of small quantities of liquid. Examples include:

Medical diagnostics – Many rapid tests require mixing, sorting, or moving tiny droplets of biological samples.

Chemical synthesis – Microreactors can create safer and more efficient reactions by controlling fluid flows at very small scales.

Environmental sensing – Field-portable microfluidic devices analyze water quality, air particulates, or chemical contaminants.

All these applications demand components that are reliable, small, energy-efficient, and easy to produce. Magnetically reconfigurable ribbons meet these needs while introducing a new dimension of programmability.

Modeling for Predictive Design

The electrocapillary modeling performed in this study is particularly important for long-term development. Droplet motion on textured surfaces depends on variables such as contact angle, surface tension, friction, and geometry. Without accurate simulation tools, designing larger or more complex arrays would require extensive trial and error. The theoretical work here provides a framework for scaling up the technology and exploring new configurations with confidence.

A Step Toward Programmable Liquid Systems

This study is an example of how soft matter engineering is evolving into a field where materials can act like information-processing elements. Instead of relying solely on electronics, future systems may embed mechanical memory and reconfigurable pathways into the material itself. That means devices could become more resilient, cheaper to build, and easier to power.

Research paper:

Magnetically Reconfigurable Multistable Ribbon Arrays for Liquid Manipulation

https://doi.org/10.1016/j.device.2025.100986