Record-Setting Hydrogen–CO₂ Separation Achieved With a New Crosslinked Polyamine Membrane

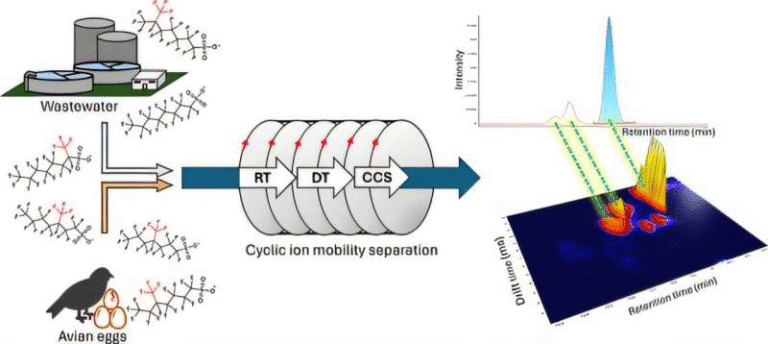

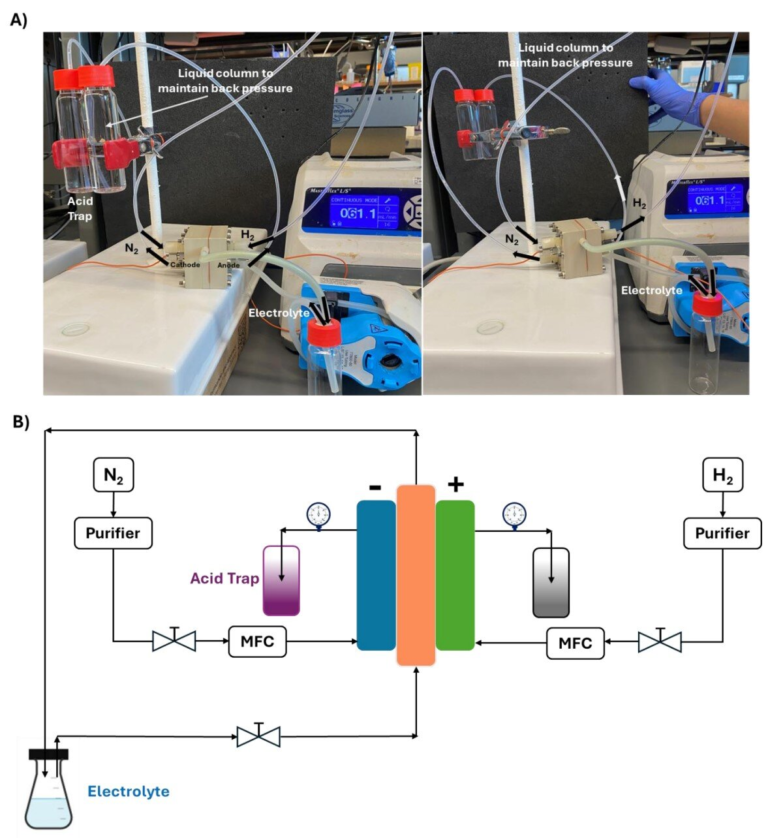

A new gas-separation membrane developed by researchers at the University at Buffalo and collaborating institutions is setting a major benchmark in the field of industrial gas processing. This membrane, made from crosslinked polyamines, achieves a hydrogen-over-CO₂ selectivity of 1,800, which is nearly 18 times higher than the previous best performance of around 100. The finding is surprising even to experts in membrane science, because the material was originally designed to attract CO₂ rather than block it. But instead of improving CO₂ permeability, the polymer binds CO₂ so strongly that it dramatically slows the gas’s movement. The result is a membrane that allows hydrogen to pass with exceptional ease while CO₂ is significantly hindered.

This discovery reverses long-held assumptions in gas separation research. For decades, chemists and engineers have leaned on the design principle that if a membrane is engineered to interact favorably with a target gas, that gas will pass through more efficiently. In this case, researchers found that too much attraction can have the opposite effect. The crosslinked polyamine network creates strong chemical interactions with CO₂ molecules, holding them in place and preventing them from moving quickly. This slowdown, while counterproductive for CO₂ capture, becomes a major advantage when separating hydrogen from CO₂ mixtures, a task that is fundamental in hydrogen production and purification.

Hydrogen often comes mixed with CO₂ in industrial processes such as steam-methane reforming, biomass conversion, and other high-temperature chemical systems. Purifying hydrogen typically requires energy-intensive steps like pressure-swing adsorption or cryogenic distillation. Membrane-based separations provide a far more energy-efficient alternative, and a membrane with a selectivity as high as 1,800 could reduce energy consumption substantially. Today, industrial chemical separations account for nearly 15% of global energy usage, making efficiency improvements in this area particularly impactful. A membrane that sharply reduces the energy demands of hydrogen purification can lower costs while also helping industries cut their carbon footprint.

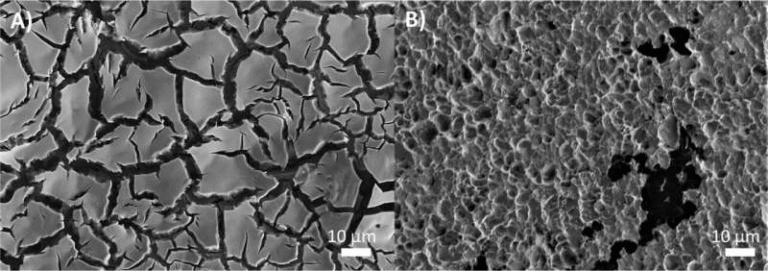

Apart from its record-breaking selectivity, the membrane shows strong promise in other practical areas. The crosslinked polyamines can be fabricated into thin-film composite membranes, the form commonly used in industrial gas separation units. This is critical because many research-grade membranes never transition to commercial use due to scalability problems. Furthermore, these membranes demonstrate self-healing behavior, which helps them recover from physical or operational damage, and they maintain stability under extreme conditions, an essential requirement for chemical and petrochemical applications.

The research team includes scientists from the University at Buffalo, Zhejiang University, the University of Colorado Boulder, and the industrial membrane company Meissner. Their experiments and molecular simulations confirm that CO₂ binding to the polymer is strong enough to significantly reduce its mobility, providing a clear explanation for the observed transport behavior. This phenomenon is consistent with the Sabatier principle, often discussed in catalysis research: if the interaction between a surface and a molecule is too weak, little happens; but if it is too strong, the molecule becomes stuck. In this context, CO₂’s strong binding to the polymer effectively traps it, slowing its passage through the membrane.

Understanding Why Hydrogen Moves Faster

Hydrogen is the smallest molecule in the universe, consisting of just two protons and two electrons. Its small size allows it to diffuse rapidly through many polymers, and in a membrane where CO₂ movement is slowed but hydrogen is unaffected, the separation factor can increase dramatically. Because hydrogen does not engage in the same strong chemical interactions as CO₂, the polymer network provides minimal resistance to its passage. This difference in interaction strength—the polymer strongly binding CO₂ but barely interacting with hydrogen—is the core of why the membrane shows such extraordinary performance.

Importance of High Selectivity in Gas Separation

Selectivity is a critical measure of a membrane’s performance. A selectivity of 1,800 means that hydrogen passes through the membrane 1,800 times more readily than CO₂. Higher selectivity generally translates to:

- Lower energy consumption for purification

- Smaller membrane area needed for industrial units

- Higher purity product streams

- Reduced operational costs

Many gas separation technologies face a trade-off between permeability (how fast gas moves through) and selectivity (how well gases are distinguished). This new membrane breaks conventional expectations by achieving extremely high selectivity without sacrificing practical fabrication potential.

Potential Applications in Clean Energy and Industry

Hydrogen purification is essential for multiple industries, including:

- Fuel cell energy systems

- Chemical manufacturing

- Refining

- Carbon-neutral fuel production

- Ammonia synthesis

Cleaner hydrogen production is a major component of global decarbonization strategies, and membranes like these directly support that effort. Because the membrane material can be manufactured at scale and withstand demanding environments, it is closer to industrial deployment than many experimental technologies.

The Unique Behavior of Crosslinked Polyamines

Polyamines contain multiple amine groups that easily form bonds with acidic gases like CO₂. When crosslinked, these polymers develop a network structure with tightly held chemical sites. In this membrane:

- CO₂ binds strongly to amine groups

- Bound CO₂ moves sluggishly

- Hydrogen, which does not bind, diffuses quickly

This dynamic flips the usual design logic. Instead of using gas attraction to enhance transport, the membrane uses gas attraction to block transport. This opens the door to new membrane-design strategies not only for hydrogen but potentially for other industrial gas pairs.

Additional Context: Why Gas Separation Matters Globally

Gas separation is hidden behind everyday products but shapes the energy and chemical landscape. To understand the broader relevance:

- Natural gas processing depends heavily on CO₂ removal.

- Hydrogen production, expected to grow significantly in coming decades, requires extensive purification steps.

- Production of oxygen, nitrogen, and helium relies on advanced separation technologies.

- Industrial separations collectively use vast amounts of energy—improving them means reducing global emissions on a massive scale.

Membrane technologies are appealing because they use no moving parts, generate no chemical waste, and often require far less energy than traditional separation methods. Innovations like this one accelerate the shift toward more sustainable industrial infrastructures.

How This Work Fits Into the Future of Hydrogen Technology

As countries invest in hydrogen as a clean fuel, efficient purification will be essential. Hydrogen fuel cells require extremely pure hydrogen to operate effectively. Impurities like CO₂ not only reduce performance but can damage some fuel cell components. A membrane capable of producing high-purity hydrogen with minimal energy input helps support the growing hydrogen economy.

If scaled and integrated into industrial systems, membranes like this could support green hydrogen initiatives, carbon-neutral fuel systems, and lower-emission chemical plants. For companies evaluating hydrogen production routes, the potential cost savings and environmental benefits make high-selectivity membranes a compelling option.

Link to Research Paper

Sabatier principle in designing CO₂-philic but blocking membranes (Science Advances, 2025)

https://www.science.org/doi/10.1126/sciadv.adz2830