Circular Economy Could Cut Lithium-Ion Battery Supply Chain Emissions by 35%, Study Finds

A new study published in Nature reveals that adopting a circular economy approach—centered on recycling, global cooperation, and smart regional policies—could cut greenhouse gas (GHG) emissions from the global lithium-ion battery supply chain by up to 35%. The research, led by Yufeng Wu and colleagues, takes a close look at how each stage of the battery’s life cycle—from mining raw materials to manufacturing and recycling—contributes to its carbon footprint.

This study offers one of the most detailed breakdowns yet of where emissions come from in the lithium-ion battery industry and how international collaboration could make a measurable difference. Given that these batteries are the backbone of electric vehicles (EVs) and renewable energy storage, cutting their supply chain emissions could be a crucial step in truly making green technologies “green.”

The Core Findings: Where Emissions Really Come From

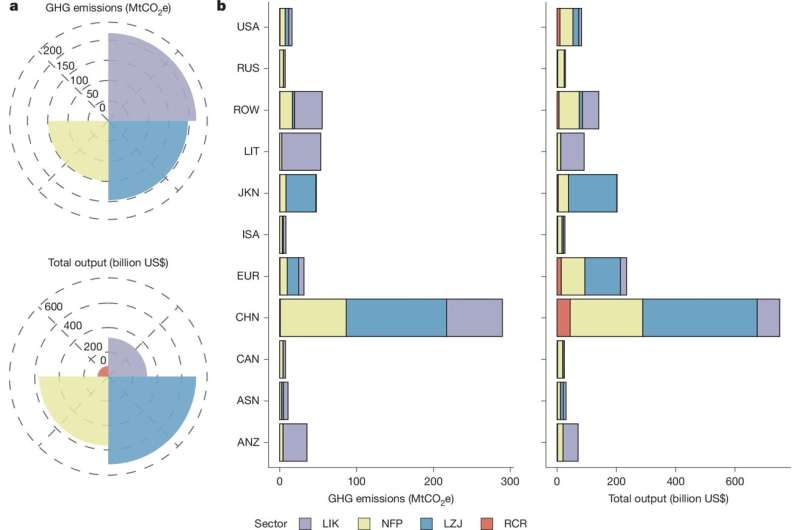

The researchers analyzed the entire global lithium-ion battery supply chain, which stretches across continents—mining in places like Australia, Chile, and the Democratic Republic of Congo, refining in China and South Korea, and assembly across North America, Europe, and Asia. Using a new model they developed, called the Lithium-cycle Computable General Equilibrium (LCCGE) model, they combined life-cycle assessment (LCA) data with global economic modeling.

Here’s what they found:

- Mining minerals (such as lithium, cobalt, and nickel) is responsible for 38.52% of total emissions—the largest share of the battery’s carbon footprint. However, this part of the supply chain only contributes 18.78% of the total economic value of the battery.

- In contrast, cathode production, which happens further down the chain, generates 34.82% of emissions but creates 42.56% of the economic value.

This creates what the authors call a “value–emission paradox”—the segments of the supply chain that make the most money tend to emit less, while those that make less tend to pollute more.

In simple terms, the dirtiest parts of the supply chain (like mining and refining) aren’t necessarily the ones that profit the most.

How Circular Economy Can Help

The circular economy approach proposed in the paper centers around recycling and reusing battery materials, reducing waste, and re-entering valuable metals like lithium, cobalt, and nickel into production. The study modeled several future scenarios, comparing traditional linear production with circular strategies that include recycling and international cooperation.

Under a “consumer-oriented recycling” approach, emissions could be reduced by around 16% globally by 2060. But when global collaboration is added—through technology sharing, trade coordination, and region-specific policies—the model predicts a much greater drop: 35.87% fewer emissions overall.

Breaking it down by region:

- United States: 39.14% reduction in emissions intensity

- European Union: 37.28% reduction

- China: 42.35% reduction

These numbers show that when countries align their recycling strategies, technology standards, and trade agreements, the environmental benefits compound.

However, the authors caution that these reductions depend on robust international cooperation—something not always easy to achieve. Since the supply chain is global, policies in one country can easily be undermined by inaction in another.

The Global Cooperation Challenge

The study warns that without cooperation, regional imbalances could worsen. Many countries that mine raw materials for batteries—such as those in Africa and South America—generate large amounts of emissions but receive little of the economic reward.

This raises an important question: who benefits from circular economies, and who bears the cost?

If recycling infrastructure and policy advantages are concentrated in richer countries, poorer, resource-rich nations could be left behind, continuing to shoulder environmental burdens without reaping financial benefits. The authors argue that a “fair and inclusive circular economy” must include global agreements ensuring shared technology, equitable profits, and environmentally responsible trade.

Understanding the Supply Chain’s Complexity

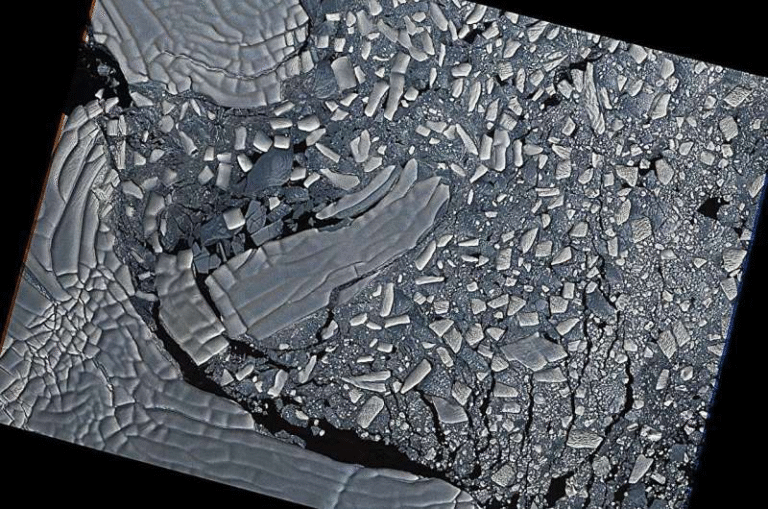

The lithium-ion battery supply chain is one of the most globally intertwined industrial systems on Earth. A single EV battery can involve over a dozen countries.

- Raw materials are mined in one region, refined in another, and turned into battery cells somewhere else.

- Cathode and anode materials are usually produced in Asia, particularly China, which dominates these sectors.

- Battery assembly is often located near vehicle manufacturers in Europe or North America.

- Finally, used batteries are shipped across borders for recycling—if they’re recycled at all.

Each transport, trade, and transformation step adds emissions. This complexity means reducing carbon output isn’t as simple as improving efficiency in one stage—it requires a coordinated system-wide transformation.

What Is a Circular Economy?

In a traditional, linear economy, products are made, used, and then discarded. A circular economy aims to close that loop—keeping materials in use for as long as possible through recycling, refurbishing, and repurposing.

For batteries, this means:

- Designing cells and packs for easier disassembly.

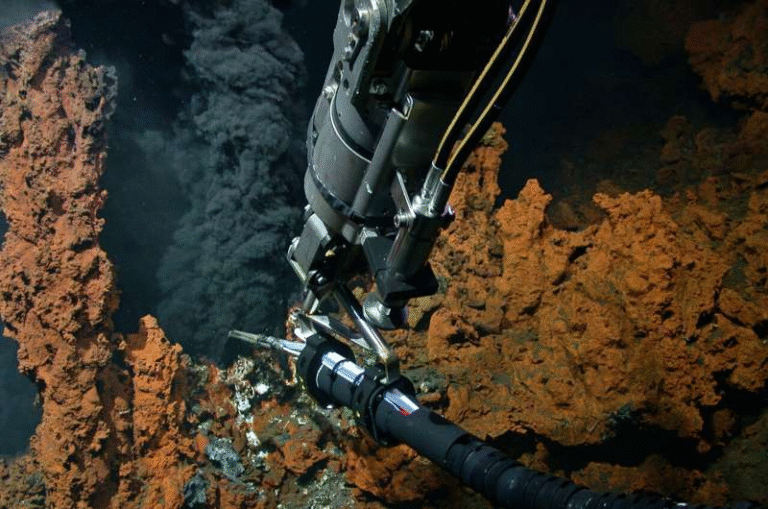

- Creating efficient recycling processes to recover metals like lithium, cobalt, and nickel.

- Reducing dependence on new mining.

- Encouraging policies that reward sustainable production and recovery.

In addition to lowering emissions, circular systems can stabilize supply chains by reducing dependence on volatile raw material markets. For example, lithium and cobalt prices have fluctuated sharply in recent years, partly due to geopolitical factors.

By recovering metals from used batteries, countries can improve their resource security while cutting emissions at the same time.

A Model for Future Climate Policy

The LCCGE model developed for this study is one of the first to blend economic and environmental data on such a global scale for batteries. It accounts for trade flows, technological progress, and carbon intensity changes over time.

The model projects scenarios up to 2060, evaluating how policies could influence both emission intensity (emissions per unit of economic value) and total emissions.

While the study finds that circular economy strategies can substantially lower emission intensity, absolute emissions could still rise as global battery demand skyrockets. Electric vehicles, grid-scale storage, and portable electronics are all driving exponential growth in battery production.

So, while a 35% cut in intensity is impressive, real-world emissions might still increase if production volumes triple or quadruple—something policymakers need to keep in mind.

The Equity Factor: Who Wins and Who Loses

Another critical point raised in the paper is the uneven distribution of value and emissions.

- Resource-rich nations often bear the environmental and social costs of mining.

- Manufacturing hubs like China capture much of the economic value.

- Consumer markets in Europe and North America enjoy the final products—electric cars, phones, and storage systems—without seeing the direct pollution.

To create a genuinely sustainable circular economy, the researchers emphasize global fairness: shared responsibility, transparent value chains, and equitable access to recycling technologies.

Why This Study Matters

This research matters because it moves the discussion beyond simple recycling. It shows that global cooperation, policy design, and economic fairness are just as important as technological innovation.

If countries coordinate their efforts—sharing recycling technologies, harmonizing regulations, and encouraging circular trade—they can collectively make a massive impact on emissions.

The paper sets an ambitious but realistic benchmark: a 35% reduction in global emissions intensity for lithium-ion batteries through circular economy strategies. It also makes a strong case that climate-friendly technology needs to look not only at the product (the battery or the EV) but also at its entire supply chain.

For a truly clean energy transition, we must ensure that the clean technologies themselves are produced cleanly.

Research Paper: A circular economy approach for the global lithium-ion battery supply chain – Nature (2025)