New Research Shows Bamboo Tissue Paper Isn’t as Eco-Friendly as It Seems

In recent years, bamboo tissue paper has gained a reputation as a greener, more sustainable alternative to traditional wood-based tissue products. Many shoppers assume that choosing bamboo automatically means choosing a lower-impact option. However, new research from North Carolina State University suggests that this popular belief doesn’t hold up when we look closely at the full environmental footprint behind the product. In fact, the study shows that bamboo tissue made in China can have a higher carbon footprint than conventional tissue made in the United States or Canada, primarily due to differences in manufacturing technologies and energy sources.

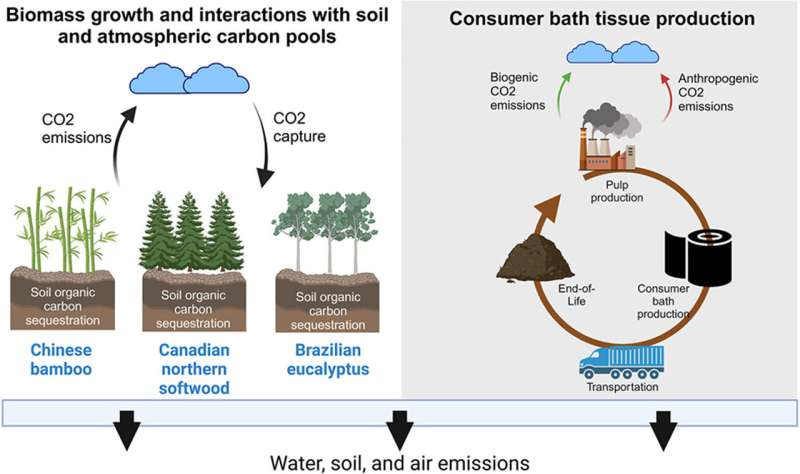

This new work, published in Cleaner Environmental Systems, presents a detailed life-cycle comparison between bamboo-based tissue produced in China and wood-based tissue produced in North America. The researchers assessed everything from raw materials to manufacturing, transportation, emissions, environmental effects and end-of-life stages. Their findings reveal that the biggest driver of environmental impact isn’t the fiber source itself—it’s the underlying energy grid and tissue-making technology used during production.

The Core Findings of the Study

The researchers found that bamboo biomass as a raw material doesn’t inherently create more greenhouse gases than wood. Bamboo, just like Brazilian eucalyptus or Canadian softwood, undergoes similar processing steps when converted into pulp. The real issue lies in the energy-intensive parts of the tissue-making process, and in this case, China’s coal-dependent power grid makes a huge difference in total emissions.

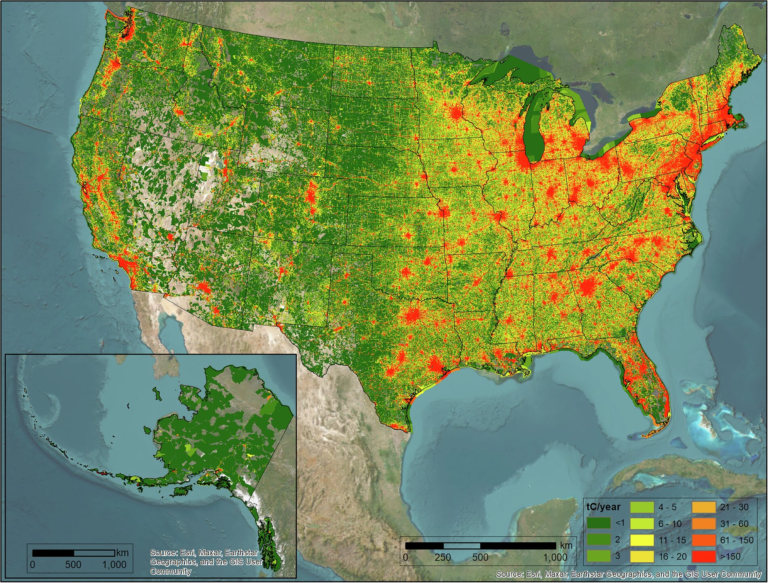

The study measured carbon output in terms of kilograms of CO₂ equivalent per ton of tissue produced. Here are the key comparisons:

- Chinese bamboo tissue: nearly 2,400 kg CO₂-eq per ton

- Wood-based U.S. tissue: 1,824 kg CO₂-eq per ton

- U.S. tissue made with a bamboo-wood blend: about 2,041 kg CO₂-eq per ton

- Tissue made with advanced CTAD technology:

- Wood-based: 2,531 kg CO₂-eq per ton

- Bamboo-wood blend: 2,739 kg CO₂-eq per ton

The data clearly shows that bamboo isn’t the fundamental environmental problem. Instead, the power grid and the technology used for drying and converting pulp have a far larger impact. China’s continuing reliance on coal leads to significantly higher emissions compared to North America, where cleaner energy sources are much more common.

Interestingly, the researchers also found that when bamboo tissue is produced in regions with clean electrical grids, the environmental differences largely disappear. This reinforces the idea that greener manufacturing—not different fibers—is the real key to lowering emissions.

Environmental Impacts Beyond Carbon

The study didn’t just look at carbon emissions; it also evaluated environmental categories such as smog formation, respiratory effects, and ecotoxicity. In these areas, Chinese bamboo tissue performed worse than U.S. wood-based tissue. Again, these differences weren’t due to the bamboo itself, but to the coal-powered manufacturing systems and the emission-heavy industrial processes tied to them.

It’s a reminder that sustainable products need more than a “natural” or “plant-based” label. Without clean manufacturing, even fast-growing, renewable resources like bamboo can yield higher impacts.

Why Consumers Often Misinterpret Bamboo Products

Part of bamboo’s appeal is its image. It’s often marketed as a tree-free, fast-renewing, environmentally friendly material. Bamboo grows quickly, requires fewer pesticides, and can be harvested without killing the plant. All of that is true—but it doesn’t tell the whole story.

The study’s researchers explain that the trees used for conventional tissue are also plantation-grown, harvested, and replanted—just like bamboo. Modern forestry for tissue production does not involve cutting down old-growth forests. Because of this, bamboo and wood pulp aren’t as different as many people assume.

Another common misconception is that bamboo tissue must be greener simply because bamboo is a non-tree crop. While bamboo has its advantages, the environmental reality comes down to energy, manufacturing, and transportation, all of which can outweigh benefits from the raw material itself.

The Role of the Sustainable & Alternative Fibers Initiative

The study’s authors are part of the Sustainable & Alternative Fibers Initiative (SAFI) at NC State University. SAFI is the world’s largest research coalition focused on advancing knowledge about both conventional and alternative fiber sources. The initiative partners with over 30 organizations across industry, academia and government. Their goal is to encourage more responsible fiber sourcing and more climate-aware manufacturing systems.

This study contributes an important perspective: fiber innovation must go hand-in-hand with clean energy and better production technology. Switching materials alone won’t significantly reduce emissions unless the underlying manufacturing infrastructure also becomes more sustainable.

Why Energy Grids Matter More Than Fiber Types

When evaluating the environmental footprint of any paper product, a life-cycle assessment reveals that the conversion phase—turning pulp into finished tissue—is extremely energy-heavy. This includes:

- Pulp digestion

- Bleaching

- Drying (typically the most energy-intensive step)

- Cutting

- Packaging

If the power grid relies heavily on coal, as is still the case in many regions of China, emissions in this phase increase dramatically. This is why the study found such a large gap between Chinese bamboo tissue and U.S. wood-based tissue.

The takeaway is straightforward: cleaner grids reduce emissions far more effectively than switching from wood to bamboo.

Adding More Context: How Life-Cycle Assessment Works

To better understand why the findings matter, it’s helpful to know how life-cycle assessments (LCAs) operate:

- Raw Material Sourcing – Land use, harvesting, fertilizer use, soil carbon changes.

- Manufacturing & Processing – Energy consumption, water use, chemical treatments.

- Transportation – Shipping distances and modes, fuel usage.

- Use Phase – How the product is consumed and disposed of.

- End-of-Life – Recycling, landfill emissions, wastewater processing.

In nearly all paper-related LCAs, the manufacturing energy dominates the total emissions. Because bamboo tissue often travels long distances (China to North America or Europe), transportation also adds a notable footprint, though not as large as manufacturing.

Should Consumers Stop Buying Bamboo Tissue?

Not necessarily—but this study highlights that bamboo tissue is not automatically greener. Consumers should consider:

- Where the bamboo tissue is produced

- What kind of energy the factory uses

- Whether the manufacturer invests in cleaner drying technologies

- How far the product travels

If bamboo tissue is produced in a region with a cleaner power grid—or if the manufacturer uses renewables—then bamboo can indeed be part of a more sustainable future. But when it’s made in coal-reliant regions, the environmental benefits diminish quickly.

Looking Ahead: How the Industry Can Improve

Manufacturers can significantly reduce emissions by:

- Transitioning to renewable energy sources

- Upgrading to energy-efficient tissue-making technologies

- Sourcing bamboo from regions with cleaner grids

- Investing in carbon-capture and wastewater-treatment improvements

Consumers, in turn, can push for transparency by supporting brands that publish their LCA data or detail their energy sources.

Full Research Paper

Comparative life cycle assessment of bamboo-containing and wood-based hygiene tissue: Implications of fiber sourcing and conversion technologies

https://doi.org/10.1016/j.cesys.2025.100337