Backyard Leafhopper Insects Are Inspiring Mass-Produced Invisibility Particles for Future Technology

When most of us spot a leafhopper hopping around a backyard plant, it barely registers as anything more than a tiny green insect. But scientists have discovered that these unassuming bugs are quietly carrying out one of nature’s most impressive feats of nanotechnology. Leafhoppers manufacture microscopic structures that help them stay hidden from predators, and now researchers have figured out how to recreate these structures at an industrially meaningful scale.

A research team at Penn State University has developed a new high-speed manufacturing platform capable of producing synthetic versions of leafhopper nanostructures—called brochosomes—at a rate of more than 100,000 particles per second. This breakthrough could pave the way for new materials used in camouflage, optics, sensing, energy systems, and even medicine.

What Makes Leafhoppers So Special at the Nanoscale

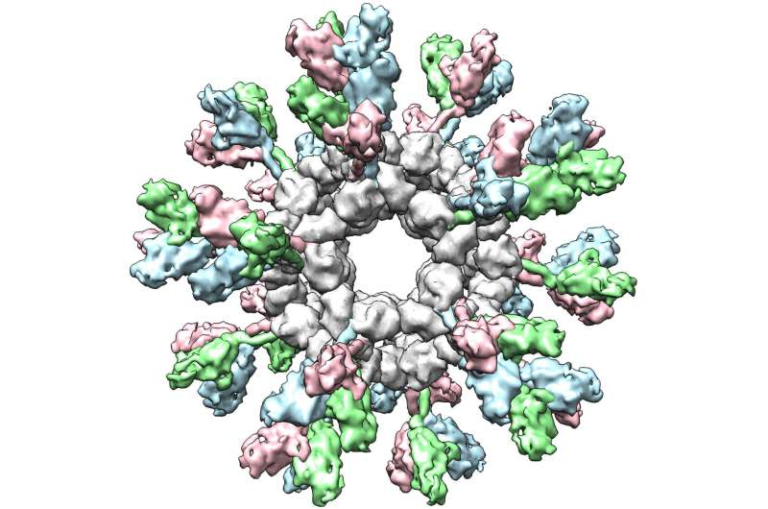

Leafhoppers are small insects, but they are remarkable engineers. Their bodies are coated with brochosomes, which are tiny hollow particles that resemble soccer balls covered in uniform nanoscale pores. Each brochosome is smaller than a grain of pollen, yet its architecture is extremely precise and complex.

These structures are not decorative. They play a critical role in helping leafhoppers avoid detection. Many of their predators, including birds and reptiles, can see ultraviolet (UV) light. Brochosomes are designed with pore sizes that absorb UV wavelengths, making the insects far less visible to animals with UV vision. At the same time, the particles scatter visible light, creating a highly effective anti-reflective coating that prevents glare.

The result is natural camouflage that works across angles and lighting conditions. To predators, leafhopper wings appear nearly non-reflective, helping the insects blend seamlessly into their surroundings.

Why Scientists Have Been Fascinated by Brochosomes

Brochosomes have long intrigued researchers, particularly in the fields of materials science and optics. Their ability to manipulate light so effectively using purely physical structure—rather than pigments or chemicals—makes them especially valuable as a design model.

However, reproducing brochosomes synthetically has been a major challenge. Their fully three-dimensional geometry and nanoscale pores push beyond what conventional nanofabrication tools can reliably create, especially in large quantities. Previous attempts managed to replicate their structure, but only at very limited scales that were impractical for real-world use.

A Major Leap in Synthetic Brochosome Production

The Penn State team, led by mechanical and biomedical engineering professor Tak-Sing Wong and postdoctoral researcher Jinsol Choi, has been working on synthetic brochosomes for nearly a decade. Their latest work represents a significant leap forward.

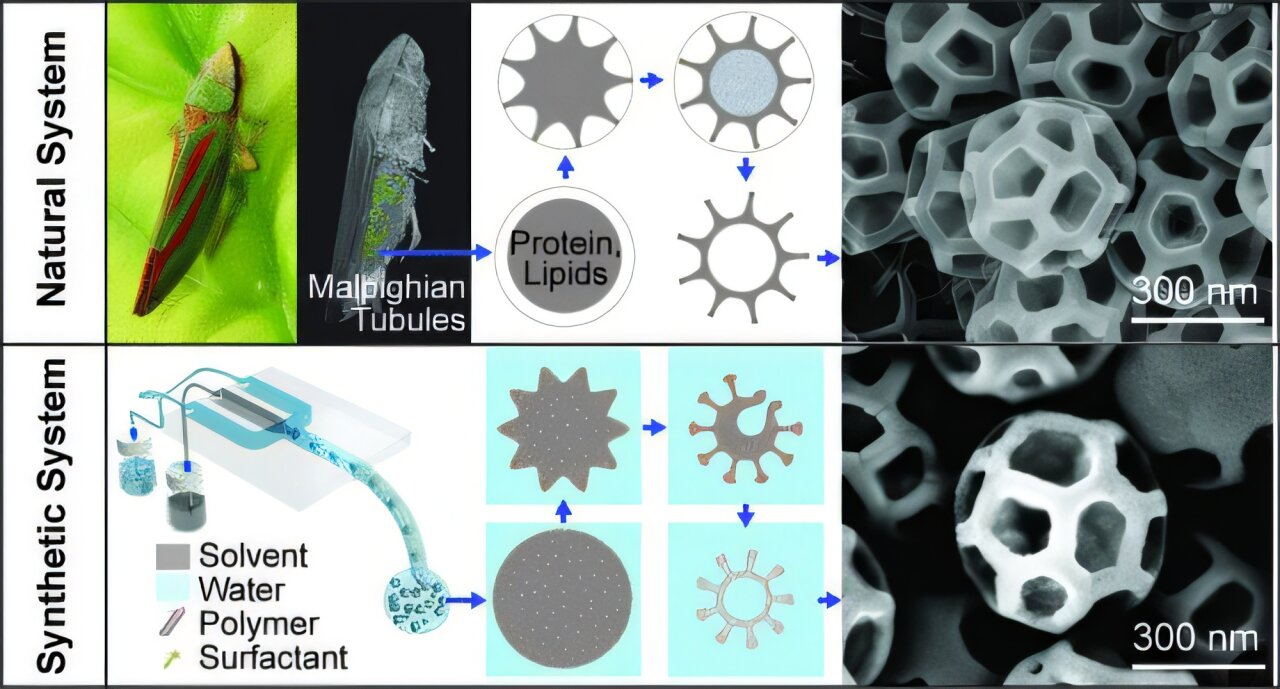

The researchers developed a microfluidic manufacturing platform that mimics how leafhoppers naturally form brochosomes inside their bodies. In insects, brochosomes are created within the Malpighian tubules, where proteins and lipids self-assemble inside tiny droplets, forming ripples that eventually become the porous shell.

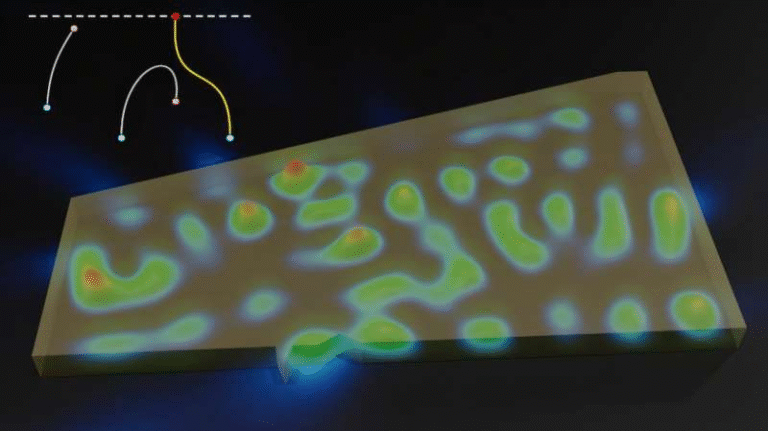

Inspired by this biological process, the research team designed a tiny chip with microscopic channels that generate identical droplets at high speed. Each droplet contains carefully engineered polymers that either attract or repel water.

As the droplets evaporate, polymers migrate toward the surface and spontaneously organize themselves. This self-assembly process naturally forms the evenly spaced pores that define brochosomes. The bending of the droplet surface and the infiltration of water droplets determine the final pore size and structure.

By adjusting polymer chemistry, molecular length, and droplet size, the researchers were able to precisely control the geometry of the final particles. This allowed them to recreate brochosomes similar to those produced by different leafhopper species.

Speed and Scale That Were Previously Impossible

What truly sets this platform apart is its speed. Traditional nanofabrication techniques often produce only a handful of particles per second and require multiple complex steps. In contrast, this new system produces approximately 140,000 fully formed synthetic brochosomes every second.

Because the structure forms through self-assembly rather than carving or sculpting, the process achieves both nanoscale precision and exceptionally high throughput. This combination has been largely unattainable using conventional manufacturing approaches.

The team believes the platform can be scaled even further, potentially increasing production rates by 10 to 1,000 times, making commercial applications far more realistic.

Optical Performance That Matches Nature

Tests showed that the synthetic brochosomes behave optically almost exactly like their natural counterparts. When applied as a coating, the particles dramatically reduce reflected light across a wide range of wavelengths and viewing angles.

This is a major advantage over traditional anti-reflective coatings, which typically work only for specific angles or narrow bands of light. The brochosome-based coatings remain effective regardless of where the light comes from, making them particularly attractive for advanced optical systems.

Potential Applications Across Multiple Fields

The implications of this technology extend far beyond invisibility concepts.

In optics and imaging, brochosome coatings could reduce glare on cameras, sensors, and displays. In solar energy, they could improve efficiency by preventing light from reflecting away from panels. In defense applications, the ability to suppress reflections across wavelengths could support advanced stealth and camouflage technologies.

Beyond optics, the particles’ hollow structure and high surface area open doors in chemical and energy research. They may serve as high-performance catalysts or sensing materials. Their porous shells also suggest future possibilities in drug delivery, medical imaging, and diagnostic technologies.

The unique combination of being hollow, highly porous, and optically functional from all viewing angles makes synthetic brochosomes a versatile platform rather than a single-purpose material.

Why Nature-Inspired Manufacturing Matters

This work highlights a broader trend in science: learning from nature’s manufacturing strategies rather than trying to force solutions using brute-force engineering. Leafhoppers do not carve brochosomes into shape. They rely on molecular self-assembly and interfacial physics, allowing complex structures to emerge naturally.

By copying this approach, researchers are finding ways to create materials that are not only sophisticated but also scalable. A patent application has already been filed for the technology, underscoring its commercial potential.

Looking Ahead

The Penn State team plans to further scale the platform and explore its use in pigments, optical coatings, and defense-related technologies. With production speed no longer a major bottleneck, synthetic brochosomes are moving from an academic curiosity toward real-world deployment.

What started as a close look at a backyard insect has become a blueprint for next-generation materials. Leafhoppers may be small, but their contribution to future technology could be enormous.

Research Paper:

https://doi.org/10.1021/acsnano.5c12763