Breakthrough in Sodium Solid-State Batteries That Work Even Below Freezing

A major leap has been made in the development of sodium-based all-solid-state batteries that can perform strongly not only at room temperature but also in subzero conditions.

Researchers from the University of Chicago’s Pritzker School of Molecular Engineering (UChicago PME), working with collaborators from institutions including the A*STAR Institute of Materials Research and Engineering in Singapore, have developed a way to stabilize a metastable structure in sodium solid electrolytes. This discovery helps sodium-based batteries reach ionic conductivities far beyond what was previously possible, bringing them closer to competing with lithium-based systems.

Why Sodium Matters

Most of today’s advanced battery research is focused on lithium-ion and lithium solid-state batteries. Lithium batteries are powerful, energy dense, and widely used in electric vehicles, electronics, and large-scale grid storage. However, lithium is expensive, its mining process has a heavy environmental footprint, and there are growing concerns about its availability as global demand skyrockets.

Sodium, on the other hand, is far more abundant, cheaper, and less damaging to source. It is also chemically similar to lithium, making it a promising alternative. The challenge so far has been that sodium-based solid-state batteries typically suffer from low ionic conductivity at room temperature, and they perform even worse in cold climates. This has limited their practical use despite the clear advantages of sodium as a material.

The new study helps overcome this bottleneck by stabilizing a unique material phase that exhibits remarkably high ionic conductivity, even when the temperature dips below freezing.

The Core Breakthrough

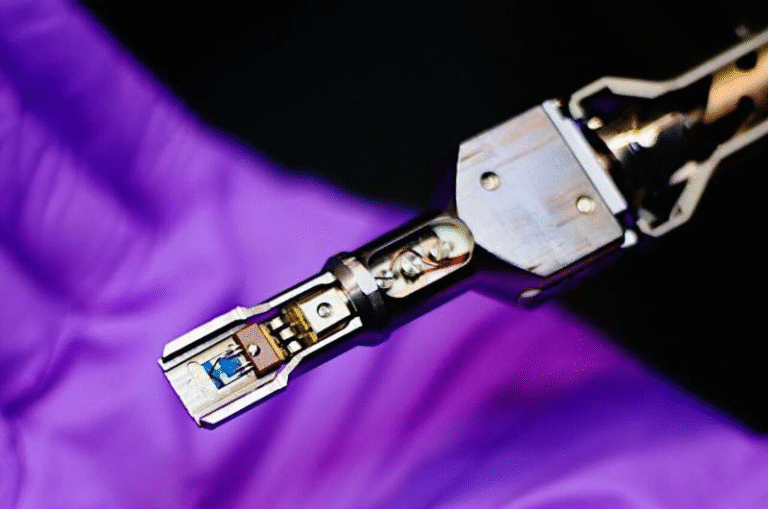

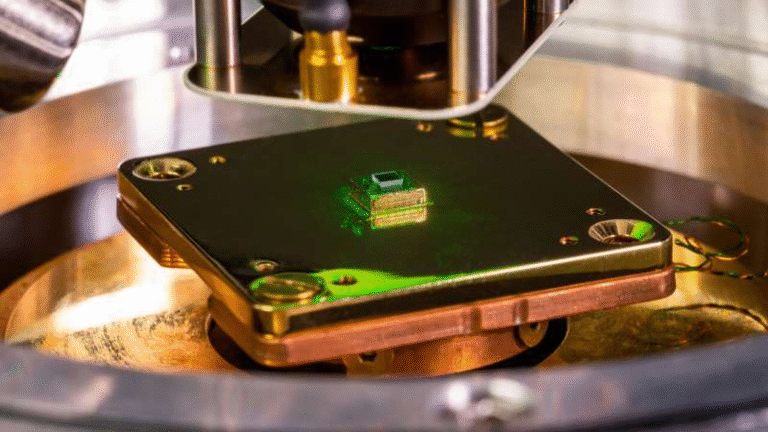

The research team focused on sodium hydridoborate, a type of material known for its potential as a solid electrolyte. What they did differently was apply a well-known technique in materials science—heating the substance until it began to crystallize and then rapidly cooling it. This process allowed them to lock in a metastable crystal structure that does not normally remain stable under ambient conditions.

- This metastable phase achieved an ionic conductivity of about 4.6 millisiemens per centimeter at 30°C (room temperature).

- Even at –10°C, the material still demonstrated around 0.3 millisiemens per centimeter, an impressive result for sodium-based electrolytes.

- For comparison, this conductivity is at least one order of magnitude higher than previously reported sodium electrolytes, and in some cases three to four orders higher than the precursor material itself.

This level of performance is critical because high ionic conductivity ensures that sodium ions can move quickly through the electrolyte, which directly impacts how efficiently a battery can charge and discharge.

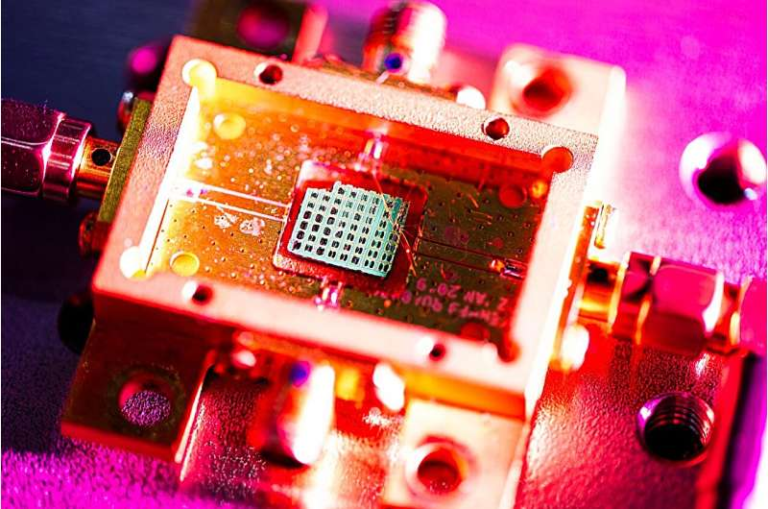

Thick Cathode Design

The innovation didn’t stop at the electrolyte. The researchers also explored the use of O3-type cathodes coated with a chloride-based solid electrolyte. This pairing allowed them to create thick, high-areal-loading cathodes, a design feature that improves the theoretical energy density of the battery.

- The cathodes reached loadings of about 45 mg per square centimeter and were around 310 micrometers thick.

- In a full-cell setup using tin (Sn) as the anode, the system delivered approximately 3.1 mAh/cm² at room temperature and about 2.5 mAh/cm² at –10°C.

Why does this matter? Traditional sodium batteries often rely on thinner cathodes to compensate for low conductivity, but thin cathodes mean less active material and therefore lower energy density. By demonstrating that thick cathodes can perform well with their new metastable electrolyte, the team showed that sodium batteries could be scaled up for practical, high-energy applications like electric vehicles and grid storage.

How This Differs from Previous Efforts

Past attempts to improve sodium solid-state batteries struggled with low conductivity and poor performance at moderate to low temperatures. The new metastable phase is not only more conductive but also stable enough to be used repeatedly in real battery cells.

Importantly, the technique used to create this phase—heat treatment followed by rapid cooling—is not some exotic lab trick. It is an established and scalable method in materials engineering. This makes the path toward commercial adoption more feasible, since industries are more likely to embrace processes that don’t require reinventing their manufacturing systems.

Computational Insights

Alongside experimental work, the team used molecular dynamics simulations to understand why this metastable form of sodium hydridoborate performed so well.

- They found that the motion of the anion framework in the material plays a crucial role.

- This motion creates a dynamic environment that promotes the movement of sodium ions, essentially making it easier for them to find pathways through the material.

- Interestingly, this improvement in mobility did not necessarily lower the activation energy but instead increased the population of highly mobile sodium ions.

These insights are important because they shed light on why closo-hydridoborate-based materials (boron-hydrogen cluster compounds) might be especially promising as the basis for next-generation solid electrolytes.

Why Subzero Performance Is Important

Batteries in general suffer performance losses in cold conditions, largely because ion mobility decreases at lower temperatures. For electric vehicles in colder climates, this is a major limitation. A battery that can deliver stable performance below 0°C is much more practical for real-world applications.

By showing that their new sodium battery design can deliver useful energy even at –10°C, the researchers have moved sodium batteries one step closer to being competitive in everyday conditions where lithium has so far dominated.

The Bigger Picture: Sodium vs. Lithium

It’s not really a case of sodium replacing lithium entirely. Instead, both can have roles depending on the application.

- Lithium remains the go-to choice for applications where energy density is critical, such as smartphones and long-range electric vehicles.

- Sodium could become a more sustainable and cost-effective choice for stationary energy storage (like grid batteries) and shorter-range EVs, especially when cost and resource availability are key factors.

As demand for batteries grows globally, especially with the expansion of renewable energy and electric mobility, having both lithium and sodium options will be vital. The research emphasizes that in the future, we could see gigafactories producing both chemistries side by side.

Remaining Challenges

While this breakthrough is exciting, there are still hurdles before sodium-based solid-state batteries can reach commercial scale:

- Long-term stability: How many charge-discharge cycles can these cells endure before degradation becomes an issue?

- Interface stability: Managing the boundaries between electrodes and solid electrolytes is always tricky in solid-state designs.

- Scalability: Even if the processing technique is established, producing these metastable electrolytes on a large industrial scale needs further work.

- Dendrite formation: Sodium, like lithium, can form dendrites (metallic filaments) that may short-circuit a battery. Mitigating this risk will be important.

A Quick Primer on Solid-State Batteries

For those new to the topic, it helps to understand why solid-state batteries are so sought after.

- In conventional liquid-electrolyte batteries, ions move through a liquid medium, which can leak, catch fire, or degrade over time.

- Solid-state designs replace that liquid with a solid electrolyte, which is generally safer, potentially more stable, and capable of enabling higher energy densities.

- The downside has been poor ion conductivity in many solid materials, especially at lower temperatures. That’s why breakthroughs like this one are important.

Sodium Hydridoborates and Their Potential

The star of this research is sodium hydridoborate, part of a larger class of compounds called closo-hydridoborates. These materials consist of boron-hydrogen clusters, and their structure can sometimes support fast ion conduction.

- The new orthorhombic metastable phase of sodium hydridoborate stabilized by the team is unusual but highly effective for conductivity.

- Similar strategies might work for other hydride-based or borate-based electrolytes, opening doors to even more discoveries.

Conclusion

This study represents a major advance in sodium solid-state battery research, showing that with clever materials engineering, sodium can come much closer to matching lithium in performance. With high ionic conductivity, thick cathode capability, and strong subzero operation, these batteries could pave the way for a new era of cheaper and more sustainable energy storage.

There’s still a long way to go before we see these in cars or power grids, but the research provides a roadmap and solid proof of concept. In a world where energy storage solutions are urgently needed, sodium might finally be stepping into the spotlight.