Cornell Scientists Create a Reusable Nanofiber Membrane That Cleans Water Efficiently and Sustainably

A research team from Cornell University has developed a reusable, washable nanofiber membrane that can remove harmful chemicals and pharmaceutical residues from water. The innovation, based on cyclodextrin, a starch-derived molecule, offers a more sustainable and effective solution for water purification compared to conventional filtration materials like activated carbon. It’s an exciting step forward in tackling water pollution from micropollutants — those tiny but persistent chemicals that slip through most treatment systems.

Understanding the Problem: Triclosan and Micropollutants

Before getting into the details of the membrane, it helps to understand the main target of this research: triclosan. This chemical, once popular in personal hygiene products like soaps and toothpastes, has been flagged as environmentally hazardous. It is antimicrobial, which means it kills bacteria, but when it enters rivers and lakes through wastewater, it can disrupt aquatic ecosystems. Triclosan has been shown to cause endocrine disruption, leading to hormonal imbalance in wildlife. It can also irritate human skin and trigger allergic reactions.

Although triclosan is now banned in U.S. hand and body washes, it still appears in many textiles, plastics, and personal care items. Once washed off or discarded, it accumulates in wastewater, where standard treatment processes fail to completely remove it. Over time, these pollutants enter natural waterways and accumulate in sediments, harming aquatic organisms and, indirectly, human health.

But triclosan isn’t the only culprit. Other micropollutants — including pharmaceutical drugs, antibiotics like ciprofloxacin, and UV filters such as oxybenzone from sunscreens — also persist in water systems. They are present in extremely small concentrations (often parts per billion) but can have major ecological effects. That’s why researchers have been working for years to create new filtration materials capable of removing these substances effectively and sustainably.

The Innovation: Cyclodextrin-Based Nanofiber Membrane

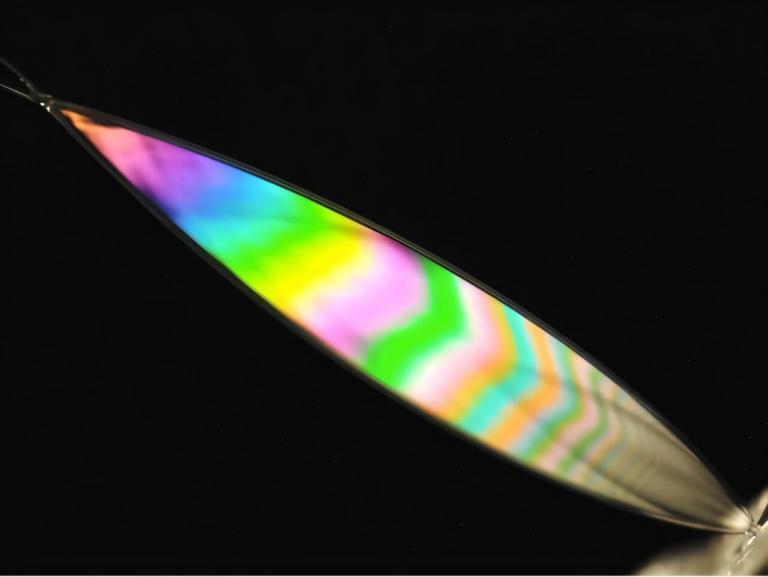

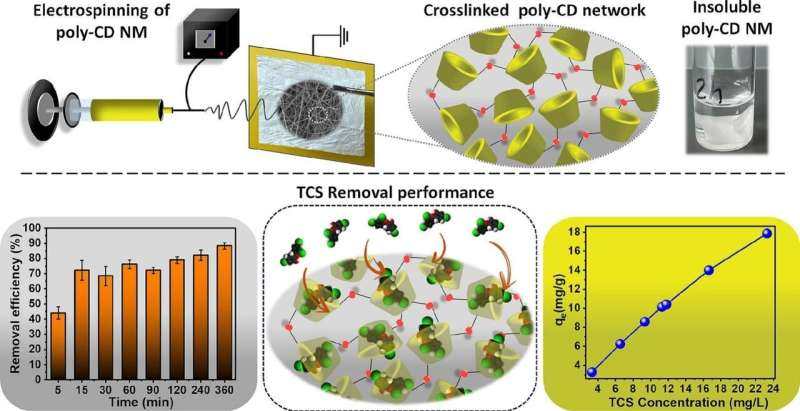

The Cornell team, led by Associate Professor Tamer Uyar in the Department of Fiber Science within the College of Human Ecology, has built a membrane made of electrospun polycyclodextrin nanofibers. The study’s lead author, Mahmoud Aboelkheir, a doctoral student in human-centered design, explains that their approach uses electrospinning — a process that employs an electric field to draw ultra-thin fibers from a liquid polymer solution.

This method allows the researchers to create fibers less than one micron in diameter (for perspective, a human hair is about 75 microns thick). Such tiny fibers provide a very high surface area, which is key for adsorption — the process by which pollutants stick to the surface of the filter material.

Cyclodextrin itself is a cyclic sugar molecule derived from cornstarch. It has a unique doughnut-shaped structure with a hydrophobic (water-repelling) cavity that traps hydrophobic pollutants like triclosan and oxybenzone. In other words, cyclodextrin acts like a tiny molecular sponge.

The novelty of this research lies in turning cyclodextrin into a standalone fibrous material. Previous filtration systems often combined cyclodextrin with other polymers or embedded it in composite materials. But in this case, the Cornell team has made a fiber composed entirely of cyclodextrin polymer, eliminating the need for any supporting structure. This design enhances the membrane’s adsorption efficiency and simplifies its application.

How Well Does It Work?

In laboratory testing, the researchers found that the membrane removed about 75% of triclosan (from a concentration of 11 milligrams per liter) within 15 minutes, and reached about 88% removal after six hours. These numbers are impressive considering that traditional activated-carbon filters often perform far less efficiently for such contaminants.

The membrane also worked against other pollutants. Tests showed significant removal of ciprofloxacin (an antibiotic) and oxybenzone, confirming the material’s broad-spectrum adsorption capacity.

Even more encouragingly, the team tested the membrane using real water samples — not just controlled lab solutions. They used water collected from Flat Rock, as well as samples from groundwater wells and wastewater treatment plants in the surrounding region. The membrane maintained high pollutant removal rates even in these complex, real-world conditions.

Reusability and Regeneration

One of the biggest advantages of this new nanofiber membrane is its reusability. Most adsorbent materials, such as powdered activated carbon, require energy-intensive regeneration processes — often involving heating or chemical washing — to restore their effectiveness. That’s not the case here.

The Cornell team’s membrane can be easily regenerated simply by washing, making it much more sustainable for long-term use. The researchers confirmed that the material maintained its structure and performance over multiple cycles of use. Since cyclodextrin is biodegradable, the membrane is not only effective but also environmentally friendly.

The Science Behind It

To verify how the membrane interacted with pollutants, the team used a technique called rotating frame Overhauser enhancement spectroscopy, a specialized form of nuclear magnetic resonance (NMR). This allowed them to observe the interactions between triclosan molecules and the cyclodextrin cavities at the molecular level. The spectroscopy was conducted at the Cornell NMR and Chemistry Mass Spectrometry Facilities under the direction of Ivan Keresztes, one of the study’s co-authors.

A Decade of Progress in Cyclodextrin Research

This new membrane builds on earlier research led by Professor Damian Helbling from Cornell’s School of Civil and Environmental Engineering. About a decade ago, Helbling’s group developed a porous cyclodextrin-infused polymer that achieved adsorption rates up to 200 times faster than conventional activated-carbon systems. However, that earlier version used cyclodextrin as an additive rather than as the primary structural component.

By transforming cyclodextrin into a self-supporting fibrous material, Uyar’s team has taken that idea to the next level. Their electrospun nanofiber membrane not only works efficiently but also functions independently as a filtering medium — without needing a polymer matrix or supporting layer. This gives it a practical edge for large-scale filtration and water-treatment applications.

Future Work and Environmental Relevance

The researchers aren’t stopping here. Ongoing projects in Uyar’s lab aim to adapt this nanofiber design to capture other persistent pollutants such as textile dyes, volatile organic compounds (VOCs), and per- and polyfluoroalkyl substances (PFAS) — the notorious “forever chemicals.” PFAS are used in non-stick cookware, waterproof fabrics, and firefighting foams, and are nearly impossible to break down in the environment. Developing membranes that can efficiently remove PFAS would be a major environmental breakthrough.

If successful, these cyclodextrin-based membranes could revolutionize water treatment, from industrial wastewater management to household filtration systems. Their lightweight, reusable, and biodegradable nature makes them ideal for sustainable water-cleaning technologies.

Why Nanofibers Matter in Filtration

The term nanofiber simply means a fiber with a diameter measured in nanometers (typically less than one micron). The smaller the fiber, the larger its surface area relative to its volume. This is crucial for filtration because contaminants have more surface to attach to.

Electrospinning — the process used in this study — creates a web-like mat of interconnected nanofibers. These mats are porous yet dense enough to trap microscopic particles and molecules. Nanofiber membranes have already found uses in air filtration, protective clothing, and biomedical applications. Their introduction into sustainable water purification represents a promising new frontier.

Environmental Impact of Micropollutants

Micropollutants are a growing concern worldwide. They come from household products, pharmaceuticals, and industrial chemicals that aren’t fully removed in wastewater treatment plants. Even at trace levels, they can interfere with aquatic life, accumulate in food chains, and disrupt reproductive and endocrine systems.

Triclosan, for instance, can lead to antibiotic resistance in bacteria and disrupt algae growth, which affects the entire aquatic food web. Similarly, oxybenzone contributes to coral bleaching, and pharmaceutical residues like ciprofloxacin can affect microbial ecosystems in sediments and water.

That’s why the development of more advanced filtration materials is so critical. Traditional treatment systems weren’t designed to handle these micro-level contaminants, but adsorptive membranes like Cornell’s nanofiber could fill that gap effectively.

Broader Significance

The Cornell team’s success represents more than just a single scientific milestone. It highlights a larger shift toward biodegradable, renewable, and energy-efficient technologies in environmental engineering. As global water scarcity worsens and pollution levels rise, the need for materials that are both effective and eco-friendly will only grow.

Unlike many synthetic adsorbents that rely on petroleum-derived polymers, cyclodextrin offers a bio-based alternative sourced from cornstarch. This means that both the raw material and the end-of-life disposal are environmentally benign. Plus, the ability to regenerate the membrane with simple washing reduces waste and operational costs.

In short, the technology combines high performance, sustainability, and practicality — three ingredients that are rarely achieved together in water treatment.

Conclusion

From triclosan-laden wastewater to sunscreen-contaminated rivers, micropollutants are one of today’s stealthiest environmental threats. The cyclodextrin nanofiber membrane designed by Cornell University’s researchers offers a clear and clever solution: a washable, reusable, biodegradable material that can efficiently remove multiple contaminants while being sustainable to produce and maintain.

The research team is already expanding its focus to address even tougher pollutants like PFAS and textile dyes, signaling that this breakthrough could evolve into a powerful tool in the global fight against water pollution.

Research Reference:

Removal of Pharmaceutical Micropollutants From Aqueous Environment by Electrospun Polycyclodextrin Nanofibrous Membrane (Separation and Purification Technology, 2026)