MIT Scientists Discover Hidden Atomic Patterns in Metals That Could Redefine Manufacturing

Researchers at the Massachusetts Institute of Technology (MIT) have uncovered a surprising new phenomenon in metal alloys — one that challenges long-standing ideas about how metals behave at the atomic level. Their findings show that hidden chemical patterns, known as short-range order, persist in metals even after they undergo extreme manufacturing processes. This discovery suggests that no matter how much a metal is heated, rolled, or deformed, its atoms never become completely random.

This revelation doesn’t just tweak an existing theory — it rewrites a key assumption in metallurgy and materials science. The study, published in Nature Communications in October 2025, shows how subtle atomic patterns remain stable even under the most violent processing conditions and how these patterns can significantly influence the performance of metals used in industries such as aerospace, nuclear energy, and electronics.

The Core Discovery: Order That Refuses to Vanish

For decades, scientists have known that metal alloys contain tiny regions where certain types of atoms prefer to cluster together. These arrangements, called chemical short-range order (SRO), are not large enough to form separate phases or crystals, but they subtly influence how a metal behaves — from its mechanical strength and heat resistance to its tolerance to radiation and corrosion.

Conventional wisdom said that once a metal is melted, rolled, and heat-treated, those delicate atomic patterns disappear. In other words, manufacturing was thought to erase atomic order, leaving a uniform, “mixed-up” structure.

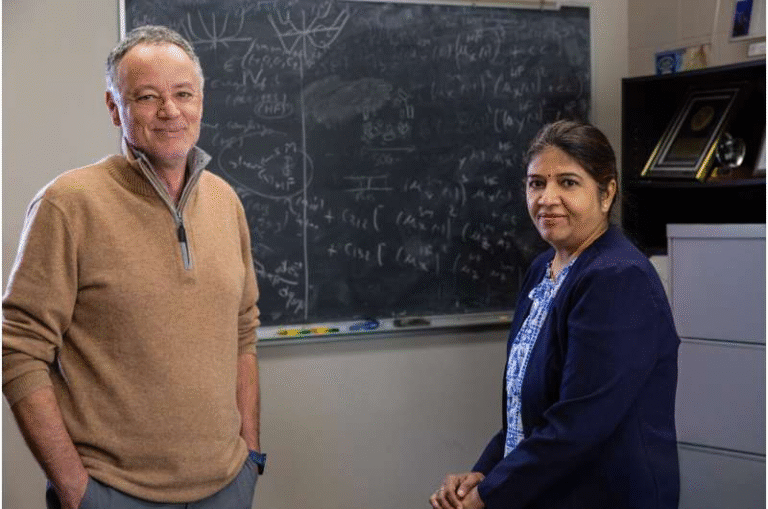

But the MIT team led by Rodrigo Freitas, TDK Assistant Professor of Materials Science and Engineering, found that these patterns don’t vanish. Instead, they survive manufacturing — and even evolve in ways that scientists never predicted.

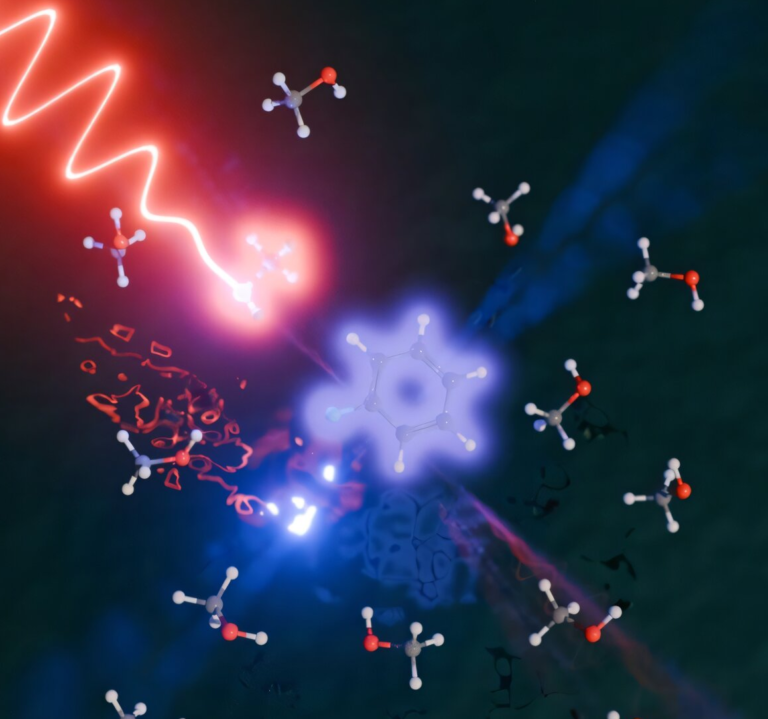

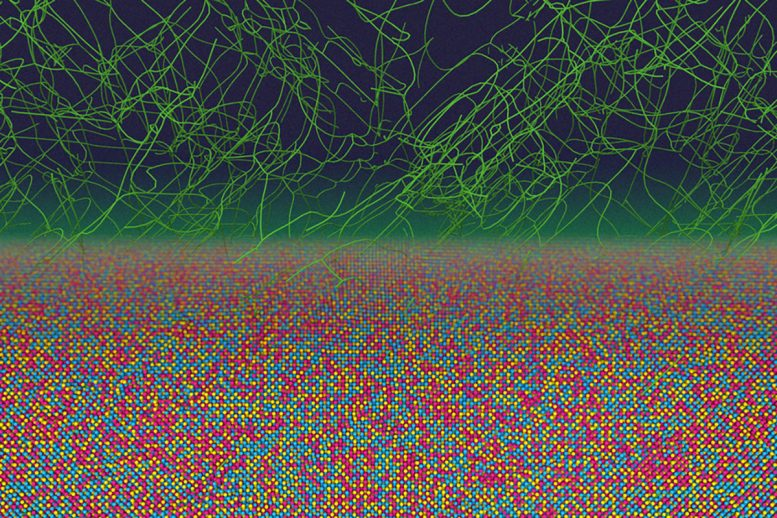

Using machine-learning-powered simulations, the team tracked how millions of atoms in a metallic alloy moved and interacted during deformation and heat treatment. What they found defied expectations: despite undergoing repeated cycles of strain and heating, the atoms never achieved complete randomness. Some areas maintained persistent chemical order, while others developed entirely new types of patterns that had never been seen before.

How the Discovery Was Made

The research began with a practical question: how fast do chemical elements mix in metals during processing? The team wanted to find the point where mixing becomes complete — when the metal’s composition becomes perfectly uniform.

To test this, the researchers simulated what happens when a metal is rolled and deformed, processes commonly used to strengthen materials. Their assumption was that deformation and heating should break and reform atomic bonds, randomizing the alloy’s internal structure.

However, the simulations showed the opposite. Even under intense mechanical processing, the alloys refused to become completely mixed. That’s when the researchers realized they were observing a new piece of physics.

The breakthrough came when the team noticed a connection between the atomic patterns and a type of crystal defect known as a dislocation — a line-like irregularity in a metal’s atomic lattice. Dislocations are crucial in determining how metals bend, stretch, and harden. They move through the lattice during deformation, and in doing so, they interact with nearby atoms.

Freitas and his colleagues discovered that these dislocations have chemical preferences. When they move, they don’t just scramble atoms randomly. Instead, they favor certain swaps over others, tending to break the weakest chemical bonds. The result is that instead of disorder, the process leads to new, stable patterns of atomic arrangement.

This interplay between dislocation motion and atomic interactions keeps the metal in what the researchers describe as a “far-from-equilibrium” state — a steady condition where order and disorder coexist.

A New Physical Model

To explain what they saw, the MIT researchers developed a simple yet powerful model showing how nonequilibrium atomic order can emerge naturally from manufacturing processes. The model incorporates two competing tendencies:

- Thermal motion, which tries to randomize atoms by mixing them evenly.

- Defect-driven motion, which organizes atoms by favoring certain chemical configurations.

These two effects balance each other, leading to persistent order even under extreme conditions. It’s similar, Freitas notes, to how living systems maintain steady internal states despite changing environments — a balance between chaos and control.

Their model doesn’t just describe the phenomenon — it can predict what kinds of atomic patterns will form under different processing conditions. That predictive power could help engineers design manufacturing methods that intentionally produce beneficial atomic arrangements.

Why This Matters

This discovery could reshape how scientists and engineers think about metals. Traditionally, alloy design has focused on choosing the right mix of elements and optimizing the grain structure (the arrangement of microscopic crystals). But the new research introduces another crucial factor: hidden atomic patterns that persist through processing.

These patterns can influence:

- Mechanical strength and ductility – The way atoms are arranged affects how easily dislocations move, which in turn determines how strong or flexible a metal is.

- Thermal and electrical conductivity – Subtle ordering changes how electrons and vibrations move through the lattice.

- Radiation resistance – In environments like nuclear reactors, SRO can reduce damage accumulation by helping defects recombine more efficiently.

- Catalytic activity – Many industrial reactions depend on the arrangement of surface atoms. Even slight atomic order beneath the surface can influence reaction rates.

By treating SRO as a design parameter, engineers could fine-tune materials at the atomic scale, achieving properties that were previously thought impossible.

Connecting the Dots: Dislocations and Atomic Behavior

To understand why dislocations play such a big role, it helps to know what they are. A dislocation is essentially a defect — a mismatch in the regular stacking of atoms inside a crystal. When a metal bends, these dislocations move through the material, allowing deformation to occur.

Most people think of dislocations as randomizers — they distort the lattice, mix things up, and create disorder. But this study reveals a subtler side. As dislocations move, they prefer certain pathways, and those preferences depend on atomic chemistry. When given a choice between breaking strong or weak bonds, dislocations take the easier route, subtly guiding how atoms rearrange.

That’s why the researchers found new types of chemical patterns — arrangements that don’t exist in metals at rest. These patterns are a product of motion itself, forming only when the metal is being processed. Once formed, they can persist long after the manufacturing is done.

From Simulation to Real-World Metals

The team’s simulations were based on high-fidelity models of alloys like CrCoNi, a well-studied system in the field of high-entropy alloys — materials known for their exceptional strength and toughness.

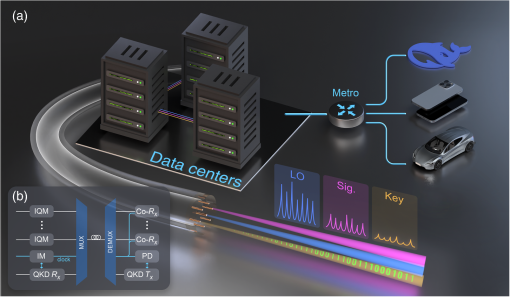

They used machine-learning-trained interatomic potentials to mimic how millions of atoms interact. This allowed them to study deformation, heating, and cooling under realistic industrial conditions, something that traditional quantum-mechanical calculations can’t do at such large scales.

The simulations revealed both standard SRO patterns (those known from previous experiments) and completely new ones that appear only at high temperatures or during active deformation. These are the nonequilibrium states the paper describes — stable but not thermodynamically relaxed.

To validate their results, the researchers created a map linking manufacturing conditions to specific chemical patterns. This map shows how changing the strain rate, temperature, or deformation path can lead to different atomic configurations.

In practice, this means engineers could eventually design a metal’s atomic order in the same way they now design its grain size or composition.

Real-World Impact

So what could this mean outside the lab?

- Aerospace and defense: Strong, lightweight alloys depend on precise atomic control. Being able to stabilize nonequilibrium patterns could lead to materials that are both tougher and lighter.

- Semiconductor and electronics manufacturing: Metals used for wiring and heat dissipation could benefit from tuned conductivity and thermal stability.

- Nuclear reactors: Metals that can resist radiation damage are critical. Controlled atomic order could make them more resilient under extreme conditions.

- Additive manufacturing (3D printing): Because printing involves rapid heating and cooling, it’s the perfect environment for creating and freezing in new atomic orders.

This discovery might even help explain past mysteries — why some alloys perform unexpectedly well, or why certain processing routes yield superior results even when composition stays the same.

Understanding Chemical Short-Range Order (SRO)

Since SRO is central to the story, it’s worth unpacking it a bit more.

In a pure metal, all atoms are the same, so the structure is perfectly uniform. In an alloy, different atoms mix together, usually forming a solid solution. If the atoms mix completely randomly, any given atom has an equal chance of sitting next to any other type.

However, in reality, chemical interactions cause preferences — some atom pairs are more energetically favorable neighbors than others. These local tendencies create SRO.

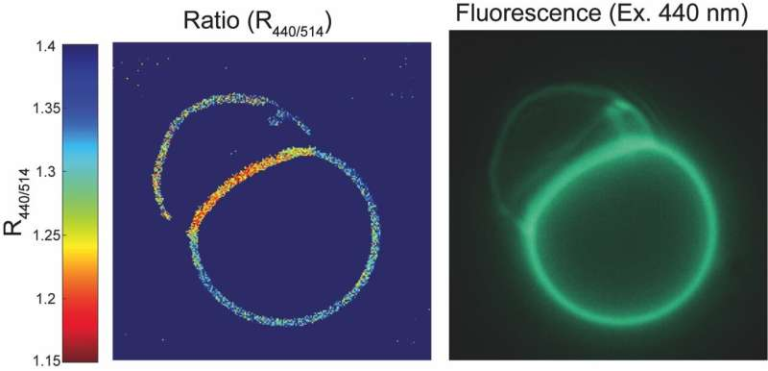

SRO doesn’t show up as visible patterns under a microscope. Detecting it requires advanced techniques like X-ray or neutron scattering, electron microscopy, or atom probe tomography. It’s a microscopic fingerprint that can dramatically change how materials behave — often without anyone realizing it.

The MIT discovery pushes this concept further by showing that SRO is not limited to static equilibrium conditions. It can persist, evolve, and even strengthen during manufacturing — a radical departure from what materials science textbooks have long said.

The Bigger Picture

The persistence of atomic order under extreme processing hints at something deeper — the idea that materials have “memory” at the atomic level. Even when exposed to massive mechanical or thermal stress, they retain traces of their past states.

Understanding this memory could open a new era of process-driven materials design, where manufacturing methods become tools for engineering atomic-scale order, not just shaping bulk properties.

The research also highlights the growing role of machine learning and atomistic simulation in materials discovery. By simulating millions of atoms and capturing complex behaviors, scientists can now explore phenomena that used to be invisible — bridging the gap between theory and the workshop floor.

As Freitas and his colleagues continue their work, they plan to study a wider range of alloys and experimental conditions to see just how universal this effect is. The ultimate goal is to turn this fundamental discovery into practical design rules that could revolutionize how we make metals.

Research Reference:

“Nonequilibrium chemical short-range order in metallic alloys” – Nature Communications (2025)