New Superconducting Cable Design Solves Defect Problems and Makes High-Tech Power Systems More Reliable

Researchers at the FAMU-FSU College of Engineering, working closely with industry partners, have developed a new superconducting cable design that dramatically reduces the risk of failure caused by defects in superconducting wires. This innovation, built around a technology known as Conductor on Round Core (CORC) wire, makes it possible for current to smoothly bypass defects and continue flowing—something that wasn’t reliably achievable with traditional superconducting wire designs.

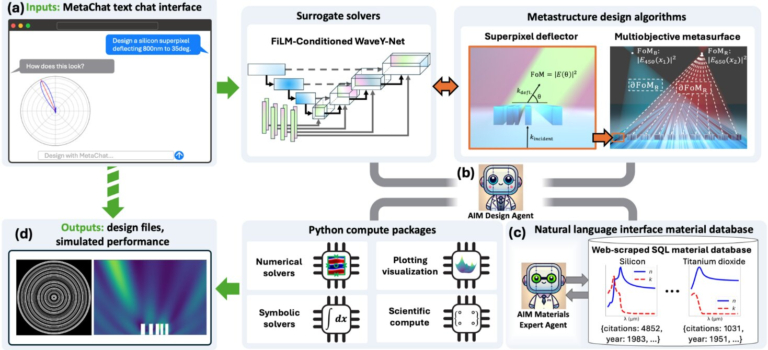

This new approach doesn’t just improve performance. It also makes manufacturing more efficient, reduces waste, lowers costs, and opens the door for broader use of superconductors in everything from fusion energy and particle accelerators to electric motors, medical equipment, AI data centers, and high-speed transportation systems.

How the New Cable Design Works

Every superconducting wire contains tiny imperfections. These defects force electrical current to move around them, which can trigger hotspots, reduce power capacity, or even cause a wire to fail. Traditional manufacturing dealt with this by identifying bad segments and soldering together only the “good” pieces to create long lengths of wire—an expensive and slow process.

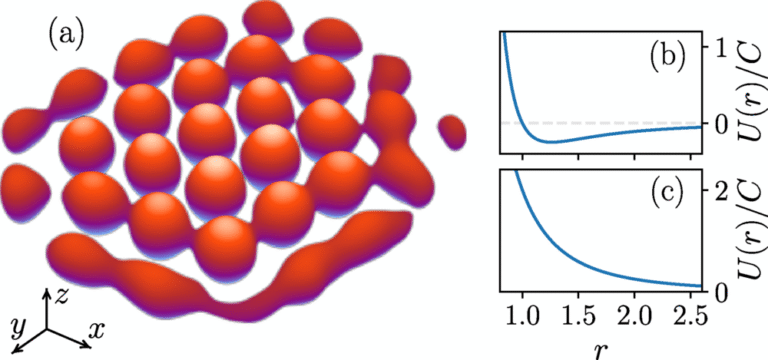

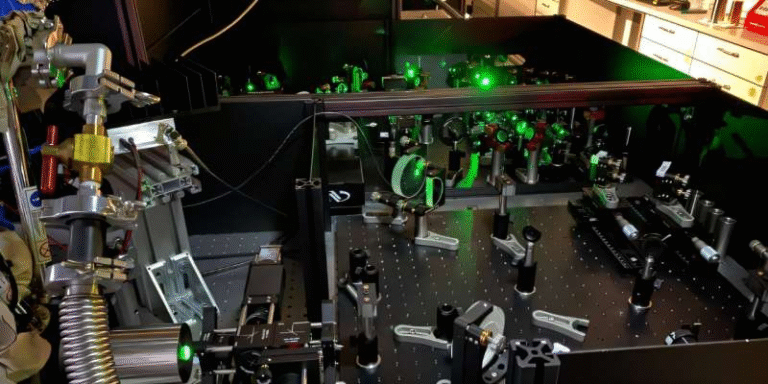

The new cable design uses a different strategy. Instead of depending on one superconducting tape, it uses multiple tapes wound together into a round shape. A CORC wire is created by tightly spiraling many superconducting tapes around a central core. These tapes are not soldered together. Instead, they rely on strong compression between the layers, which allows current to naturally move from one tape to another when needed.

This process is called current sharing, and it is the centerpiece of the new results.

If a defect appears in one tape, the current simply jumps sideways into a neighboring tape and continues traveling without interruption. Because defects are typically random, they almost never line up across multiple tapes. That makes the cable extremely tolerant of imperfections.

In the latest project, researchers tested this idea on a coil made from CORC wire that contained known defects. Despite these imperfections, the coil performed just as well as coils made from tapes that were nearly flawless. This is a major step forward because it proves that wires previously considered unusable or “low-grade” can still produce high-performance superconducting coils.

What the Experiment Demonstrated

The study is published in Superconductor Science and Technology, and it offers very specific and meaningful results.

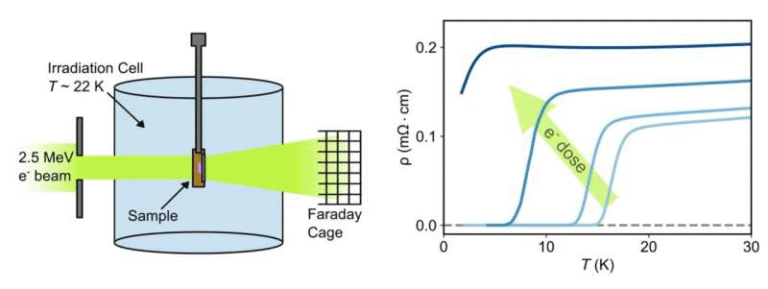

Researchers built a 4-layer CORC solenoid using 25 meters of CORC wire produced with noticeable variations in its critical current (Ic). The coil contained 81.5 total turns, and when energized, it produced a peak magnetic field of 4.6 tesla (T) at a temperature of 25 kelvins (K).

Key performance details include:

- The coil reached a critical current of 4460 amperes (A).

- It operated stably at a continuous current of 4021 A, which is 87% of its critical current.

- Power loss during operation was extremely low, confirming efficient current sharing among the tapes.

The coil also used helium gas cooling, not liquid nitrogen. Helium’s wide temperature range in gas form gives engineers greater flexibility in designing superconducting systems. This ties into a broader shift toward high-temperature superconducting (HTS) technologies, which function at temperatures up to 77 K—much easier to achieve and maintain than the near-absolute-zero conditions required by early superconductors.

The team behind this work includes researchers at FSU’s Center for Advanced Power Systems (CAPS) and industry collaborators:

- Advanced Conductor Technologies (ACT), which co-developed the CORC concept.

- SuperPower Inc., a major producer of second-generation HTS tape used in modern superconducting systems.

Their long-standing partnership began through the US SBIR/STTR programs and has continued for over a decade. ACT’s CEO has credited FSU’s scientific infrastructure and expertise for helping bring CORC cables to commercial reality since 2014.

Why This Advancement Matters

Superconducting wires allow electricity to flow with zero electrical resistance, making them incredibly powerful and efficient. But their widespread use has been limited by cost, fragility, and manufacturing challenges—especially defects in the tape.

This new cable design tackles several major barriers:

1. Reduced Waste and Lower Costs

SuperPower’s R&D leadership noted that coils made from VIC wires—a category of wires previously labeled as defective—performed just as well as coils wound from nearly perfect wires. This means manufacturers can use much more of what they produce, instead of throwing away or downgrading defective sections. Increased production yield directly translates to lower wire costs.

2. Higher Reliability and Fault Tolerance

Current sharing ensures that even if one tape has a flaw, the overall cable keeps performing. This makes superconducting systems far more dependable in high-demand environments.

3. Flexibility and Strength

Because the tapes aren’t soldered, the wire stays more flexible and stronger under tension—two qualities essential for building robust, compact coils that can handle real-world mechanical forces.

4. Broader Applications

With improved reliability and lower cost, superconducting cables become practical for many technologies, including:

- Electric motors and generators

- Magnetic levitation systems

- Electric aircraft and ships

- Fusion reactors

- Particle accelerators

- MRI and medical devices

- AI data center power systems

- Long-distance power transmission lines

Anywhere engineers need to move large amounts of electricity efficiently, superconductors offer a major advantage.

Background: What CORC Wires Are and Why They Matter

CORC wires were first developed to produce compact, flexible, round cables using multiple flat superconducting tapes. Compared to older single-tape designs, CORC wires are:

- More resistant to bending damage

- Capable of achieving high engineering current densities

- Easier to fabricate into coils and large magnet systems

- More tolerant of mechanical stress

Previous versions of CORC wire showed promising performance, including high current capacity even in strong magnetic fields above 20 T. But concerns about tape defects remained.

This new research finally demonstrates that even with significant local critical current dropouts, CORC cables can maintain excellent performance thanks to natural current sharing between tapes.

This is a turning point for HTS cables because it validates the idea that imperfection-tolerant superconductors are not only possible but practical.

The Role of High-Temperature Superconductors

Early superconductors required temperatures near absolute zero, which made them expensive and difficult to use outside of very specialized environments.

Today’s high-temperature superconductors (HTS) can operate at 77 K (the temperature of boiling liquid nitrogen). The new CORC designs push performance even further, showing strong results at 25 K using simple helium gas cooling.

This makes HTS systems:

- Cheaper to cool

- Easier to operate

- More resource-efficient

- Better suited for widespread adoption

CAPS researchers, including Sastry Pamidi and his team, continue advancing HTS coil technologies, with the goal of developing more durable, flexible, and cost-efficient superconducting solutions.

Final Thoughts

This work demonstrates a major practical improvement in how superconducting wires are designed, manufactured, and applied. By enabling current to naturally bypass defects, CORC cables greatly reduce waste, improve reliability, and strengthen the overall economics of superconducting technology.

With applications spanning clean energy, transportation, medicine, and advanced computing, this design represents a meaningful step toward making superconductivity a mainstream engineering tool rather than a specialized laboratory technology.

Research Paper:

Demonstration of current sharing around tape defects in a low-inductance CORC® wire solenoid generating a peak magnetic field of 4.6 T at 25 K

https://doi.org/10.1088/1361-6668/adedbd