Silicon Quantum Chips Achieve Industry-Level Accuracy in Manufacturing

A major breakthrough has just been reported in the world of quantum computing. The Australian startup Diraq, spun out of the University of New South Wales (UNSW), has shown that its silicon quantum chips can be built in large-scale industrial settings without losing precision. These chips have achieved the crucial benchmark of over 99% fidelity for two-qubit operations, a level of performance widely regarded as essential for practical quantum computing.

The finding was not confined to laboratory prototypes. Instead, it was demonstrated in chips manufactured through standard semiconductor foundry processes in collaboration with imec, the leading European nanoelectronics research institute based in Belgium. The results were published in Nature on September 24, 2025, under the title “Industry-compatible silicon spin-qubit unit cells exceeding 99% fidelity.”

This achievement closes an important gap between research-grade devices and industry-scale production, showing that qubits fabricated in a foundry environment can reach the same high level of reliability that had previously only been seen in carefully crafted laboratory samples. For the quantum industry, this is a milestone—because for quantum computing to move beyond experiments into utility-scale machines, high-performance qubits need to be manufactured at scale, cost-effectively, and consistently.

Why 99% Fidelity Matters

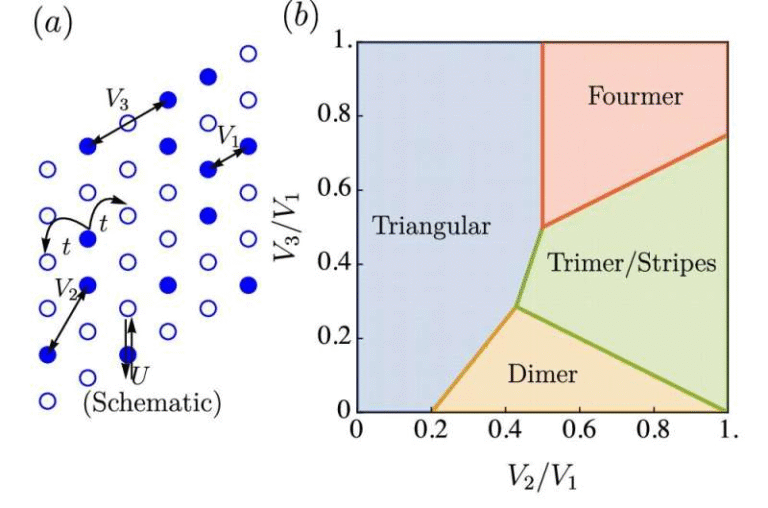

In quantum computing, fidelity measures how accurately a qubit operation can be performed. A two-qubit gate—the basic logic building block of quantum processors—needs to achieve at least 99% accuracy for fault-tolerant quantum error correction to be feasible. Below this threshold, errors multiply too quickly for correction methods to keep up.

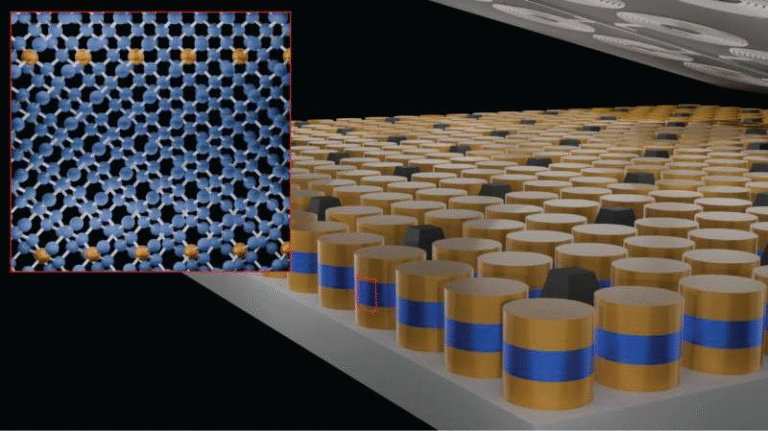

Diraq and imec’s silicon spin qubits not only reached this benchmark, but did so using CMOS-compatible processes on 300 mm wafers, the same kind of technology used to mass-produce modern computer chips. This makes their approach not only scientifically impressive but also commercially viable.

Even more encouraging, the devices were randomly selected from batches rather than cherry-picked. This means that high fidelity was not a fluke but a reproducible outcome of the manufacturing process. Such reproducibility is essential when scaling to millions of qubits, which is the estimated number required for a utility-scale quantum computer.

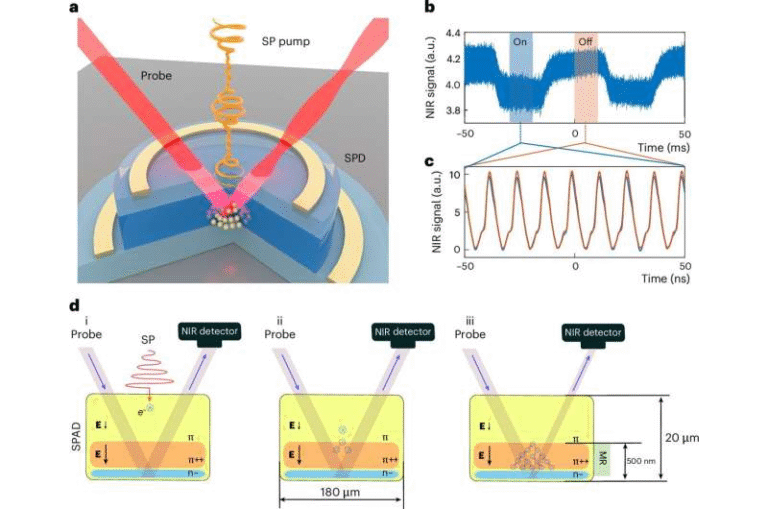

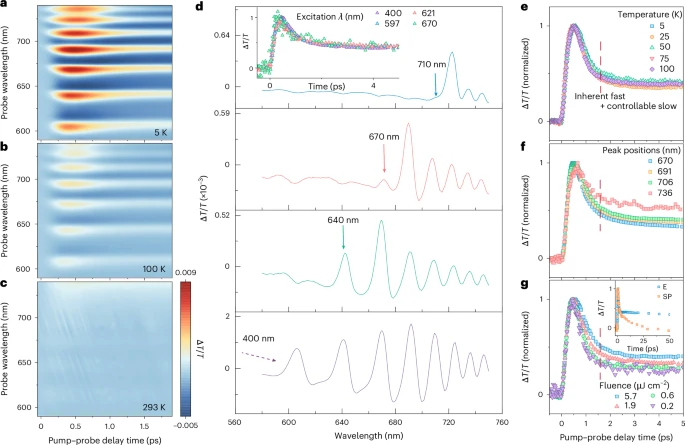

Technical Details of the Breakthrough

The Nature paper provided a detailed look at the performance of these qubits. Some of the key reported figures include:

- Two-qubit gate fidelity: Over 99% across tested devices.

- Single-qubit operation fidelity: Previously shown to reach 99.9% in similar devices.

- State preparation and measurement (SPAM) fidelity: Up to 99.9%.

- Qubit coherence times: Relaxation times (T1) up to about 9.5 seconds.

- Hahn echo coherence (T2): Around 1.9 milliseconds.

- Dephasing time (T2):* Approximately 40.6 microseconds.

These figures are all consistent with what is needed for fault-tolerant quantum computing. Importantly, the main remaining source of errors was identified as residual nuclear spin noise in the silicon substrate. Silicon naturally contains isotopes such as 29Si, which carry nuclear spins and create magnetic noise that disturbs qubits. However, with further isotopic purification—increasing the proportion of spin-free 28Si—the error rates could be reduced even more.

This indicates that fidelity levels above 99% are not only achievable but also improvable, which makes the platform promising for long-term scaling.

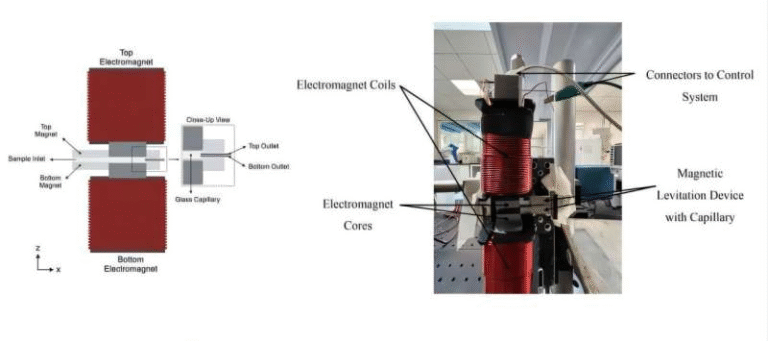

The Role of imec and Industrial Processes

A key part of this breakthrough was the use of imec’s industrial semiconductor fabrication facilities. The chips were manufactured on 300 mm CMOS lines, the same kind used for everyday microchips. This ensures compatibility with the existing global semiconductor supply chain and infrastructure.

By showing that quantum chips can be built using mainstream tools, Diraq and imec are positioning silicon qubits as a realistic contender for scalable, cost-effective quantum processors. Instead of needing exotic or custom-made fabrication methods, quantum hardware can be produced using the same lines that already build billions of transistors.

This compatibility is a massive advantage. It allows researchers to take advantage of decades of refinement in microchip manufacturing and avoid reinventing the wheel. It also reduces costs significantly, making the path toward millions of qubits far more economically viable.

What Makes Silicon Special?

Silicon is becoming the front-runner material for scalable quantum computers for several reasons:

- Compatibility with existing industry: Billions of dollars have already been invested in CMOS technology. Leveraging this infrastructure makes large-scale production realistic.

- Density of qubits: Silicon can host millions of qubits on a single chip, making it suitable for building truly large-scale processors.

- High-fidelity potential: As demonstrated by Diraq’s results, silicon spin qubits can achieve fidelities exceeding 99% for both single- and two-qubit gates.

- Integration with classical electronics: Quantum chips will need classical control electronics for error correction and operation. Silicon offers the ability to integrate both on a single platform.

Other qubit technologies, such as superconducting circuits or trapped ions, are also making rapid progress. However, these approaches often face scaling limitations due to hardware complexity, cooling, or footprint. Silicon, on the other hand, could scale in a way that matches Moore’s Law, provided fidelity and yield can be maintained.

Utility-Scale Quantum Computing

The ultimate goal is to reach utility scale—the point at which a quantum computer’s commercial value exceeds the cost of operating it. This is the metric set out by the Quantum Benchmarking Initiative run by DARPA, in which Diraq is one of 18 participating companies.

Utility-scale systems will require millions of qubits. At that scale, robust error correction can overcome the fragile nature of quantum states. But getting there depends on a manufacturing approach that delivers high-fidelity qubits cost-effectively and at volume.

Diraq’s success with imec indicates that such a pathway is opening up. Instead of being limited to laboratory devices, silicon quantum chips may now be produced in the same way as microchips used in smartphones and supercomputers.

Challenges Ahead

Despite the excitement, there are still hurdles:

- Scaling complexity: While unit cells have shown high fidelity, assembling and controlling millions of them in a single system is an immense challenge.

- Error sources: Even with isotopic purification, other sources of noise—such as charge fluctuations and crosstalk—will need to be addressed.

- Yield and uniformity: Ensuring that every qubit across a full wafer performs consistently remains an ongoing challenge.

- System integration: Cooling, wiring, and control electronics must all be integrated efficiently to operate large-scale systems.

Yet, the progress Diraq and imec have shown strongly suggests that these challenges are engineering hurdles rather than fundamental roadblocks.

Broader Context: Competing Qubit Platforms

To better understand the significance of Diraq’s work, it’s useful to compare it with other leading qubit platforms:

- Superconducting Qubits: Used by companies like Google and IBM, these have demonstrated processors with over 1,000 qubits. However, they face challenges with wiring complexity and scaling.

- Trapped Ions: Highly accurate with fidelities above 99.9%, but scaling to thousands or millions of ions is technically difficult due to physical size and control requirements.

- Photonic Qubits: Offer promise for communication and integration with fiber networks, but large-scale universal computing remains a challenge.

- Topological Qubits: Microsoft has pursued this path, but the technology is still at an experimental stage.

Silicon stands out because it merges scientific performance with industrial compatibility, making it one of the strongest candidates for scaling to utility-scale systems.

Why This Matters for the Future

Quantum computers are expected to transform fields like drug discovery, materials science, optimization, logistics, artificial intelligence, and cryptography. However, for these applications to be practical, quantum machines need to exceed the point where they deliver more value than they consume.

This is why demonstrations like Diraq’s are so important. They show that quantum computers can be built using mature, cost-effective manufacturing methods and that performance is not limited to hand-crafted lab devices.

It represents a crucial step toward moving quantum technology from the research phase to the industrial and commercial phase, where its true impact will be felt.

Reference

Industry-compatible silicon spin-qubit unit cells exceeding 99% fidelity – Nature, 24 September 2025