Lab-Grown Diamond Coatings Show Powerful Potential to Prevent Mineral Scale in Industrial Systems

Mineral buildup inside industrial pipes is a surprisingly stubborn and costly problem, affecting everything from water desalination plants to energy systems. When minerals like calcium carbonate crystallize and accumulate on pipe surfaces, they narrow flow paths, strain equipment, increase energy consumption, and demand frequent maintenance. Traditional solutions usually involve chemical additives or mechanical cleaning, but both tend to offer only temporary relief and come with environmental or operational downsides. Now, new research from Rice University suggests an innovative, long-lasting alternative: lab-grown diamond coatings engineered to naturally resist scaling.

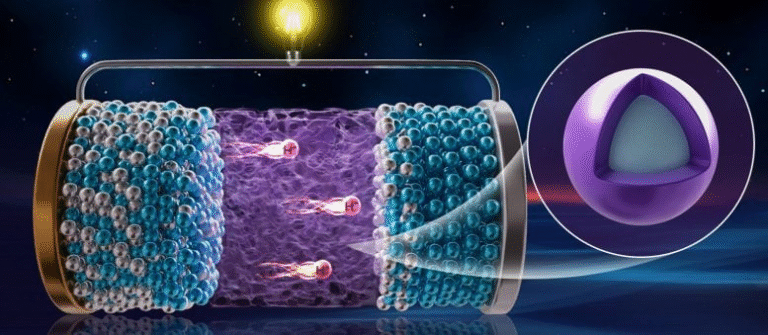

In a recent study, Rice engineers created synthetic diamond films using microwave plasma chemical vapor deposition, a well-established technique for turning gas molecules into solid diamond layers.

The researchers began by introducing methane and hydrogen gases into a specialized chamber. Microwaves then energized the gases into a hot plasma, causing the molecules to break apart. Freed carbon atoms settled onto silicon wafers and linked into the tightly packed lattice structure that defines diamond. This process produced polycrystalline diamond films that could be modified further to alter their surface properties.

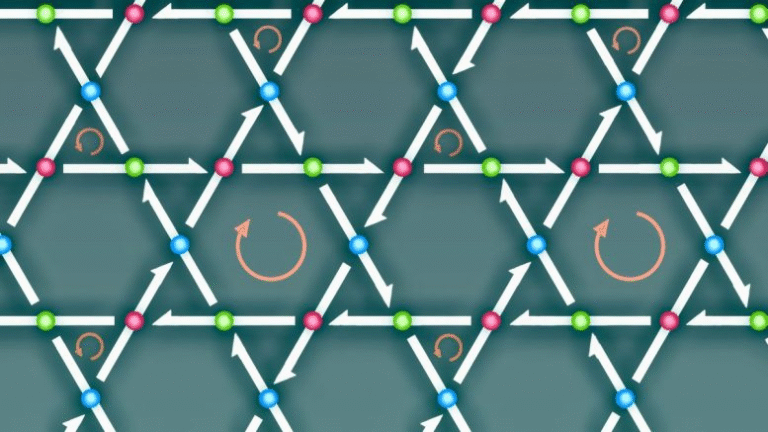

The key focus of the study was how subtle changes in surface chemistry influence the earliest stages of mineral scaling. After growing the diamond films, the team applied a range of postgrowth treatments to create different types of surface terminations—oxygen, hydrogen, fluorine, and nitrogen. Although all versions of the diamond films maintained their intrinsic strength and heat resistance, one stood out dramatically: nitrogen-terminated diamond.

During scaling tests, nitrogen-terminated surfaces accumulated more than an order of magnitude less mineral scale than any of the other treatments. Microscopy showed that while other surfaces developed dense, continuous layers of crystal deposits, the nitrogen-treated diamond displayed only small, isolated clusters. This wasn’t just a minor improvement—it was a major reduction that pointed to a fundamentally different surface behavior.

To understand why this happened, the researchers ran molecular simulations that revealed how nitrogen termination affects water behavior at the surface. Nitrogen atoms on the diamond created conditions that encouraged a tightly bound, highly stable layer of water molecules to form. This structured water layer acted like a natural shield, making it difficult for mineral ions to attach and start forming scale. In simple terms, the diamond surface became self-protecting, preventing scale from taking hold in the first place.

The team also explored whether the same chemistry could help in electrochemical systems, which frequently use boron-doped diamond electrodes. These electrodes are known for their durability and resistance to fouling, but they still face scaling challenges in many environments. After applying the nitrogen-termination technique, the researchers found that the treated electrodes collected about one-seventh as much mineral scale as untreated ones, with no performance loss. This suggests that engineered diamond surfaces could offer benefits across a range of technologies beyond piping.

To thoroughly evaluate the coatings, the researchers combined microscopy, chemical analysis, and adhesion measurements. These methods showed not only how much scale formed but also how strongly it adhered, which is important because even a thin but strongly bonded layer can cause operational issues. The comprehensive nature of the study was made possible by recent advances in producing high-quality, cost-effective diamond films and reliable surface modification methods—advances that were not widely available until very recently.

The study identifies vapor-grown polycrystalline diamond films as a promising, scalable solution for industrial sectors where mineral buildup is a persistent headache. Not only are these coatings durable, heat-resistant, and chemically stable, but they also offer passive protection, reducing the need for constant intervention. Industries such as water desalination, power generation, chemical processing, and any system involving ion-rich fluids stand to benefit significantly from such technology.

Researchers involved in the work include Xiang Zhang and Yifan Zhu as lead authors, with contributions from senior investigators Pulickel Ajayan and Jun Lou. The project draws on expertise in materials science, nanoengineering, and surface chemistry, illustrating how interdisciplinary research can uncover practical solutions for large-scale engineering challenges.

Understanding Mineral Scaling in Industrial Environments

Mineral scaling is a long-recognized issue that results from the precipitation of dissolved ions—most commonly calcium, magnesium, and carbonate—onto surfaces exposed to flowing water or brines. Once the first layer of scale forms, it grows rapidly, creating a rough surface that traps additional minerals and accelerates deposition. Over time, this buildup can cause serious problems, including:

- Reduced flow efficiency

- Higher pumping and energy costs

- Heat-transfer inefficiency in boilers and condensers

- Clogged pipes and instrumentation

- Frequent shutdowns for cleaning and maintenance

Chemical inhibitors can reduce scaling but must be used continuously and may pose environmental risks. Mechanical cleaning is labor-intensive and offers only temporary relief. This makes passive, long-lasting surface solutions—like diamond coatings—especially attractive.

Why Diamond Is an Effective Material for Industrial Coatings

Diamond is not only known for its cosmetic appeal but also for several engineering properties that make it extremely useful in industrial applications:

- Exceptional hardness, making it resistant to abrasion and mechanical wear.

- High thermal conductivity, which is beneficial in heat exchangers and other thermal systems.

- Chemical inertness, which prevents it from reacting with harsh environments.

- Resistance to biological fouling, as shown in earlier studies involving microbial growth.

The new research adds to this list by demonstrating diamond’s potential to resist mineral scaling, especially when the surface chemistry is strategically engineered. Nitrogen termination introduces a new avenue for tuning how diamond interacts with water and dissolved ions.

Broader Implications for Industrial Sustainability

Scaling is not only expensive but also environmentally impactful. Reducing reliance on chemical inhibitors helps decrease chemical discharge into ecosystems, lowers operational costs, and improves equipment longevity. The adoption of advanced coatings like nitrogen-terminated diamond could support sustainability goals across multiple sectors.

Furthermore, since the deposition method used in this study is scalable and increasingly cost-effective, it opens the door for real-world implementation—something that has often been a barrier for exotic materials.

What Comes Next?

Future research may explore:

- How nitrogen-terminated diamond performs under long-term industrial conditions.

- Whether other surface chemistries could achieve even greater performance.

- How such coatings interact with complex mixtures containing organic matter, microbes, or multiple types of minerals.

- Opportunities for integrating diamond-coated components into desalination plants, geothermal systems, and energy infrastructure.

With this study, Rice University researchers have provided a promising foundation for rethinking how industries approach mineral scaling—potentially shifting from reactive maintenance to proactive protection.

Research Paper:

Nitrogen-Terminated Diamond Films for Antiscaling Coatings

https://doi.org/10.1021/acsnano.5c13554