The Unexpected Material That Could Help Build the First Mars Colony

Scientists have taken an important step toward making life on Mars possible: they’ve figured out how to turn Martian soil into usable metals. This breakthrough could make it possible to build colonies directly on Mars without needing to transport huge amounts of material from Earth.

Researchers from Swinburne University of Technology and Australia’s national science agency, CSIRO, have successfully produced iron under simulated Martian conditions. Their work demonstrates that Mars itself has the resources necessary to support settlement building, saving both money and effort compared to shipping supplies from Earth.

Sending materials to Mars is extremely costly. For perspective, transporting NASA’s one-ton Perseverance Rover to the Red Planet cost about US$243 million. Clearly, if large-scale human settlements are to be built, relying on Earth shipments is not sustainable. This is where in-situ resource utilization (ISRU) comes into play—the concept of using local resources for building and survival.

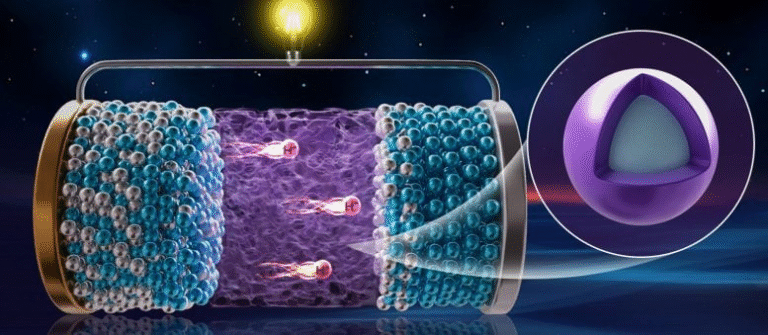

At the core of this project is the emerging field of astrometallurgy, which focuses on producing metals in space. Mars already has all the ingredients necessary for this. Its regolith (soil) contains iron-rich oxides, and its thin atmosphere provides carbon, which acts as a reducing agent in metal production.

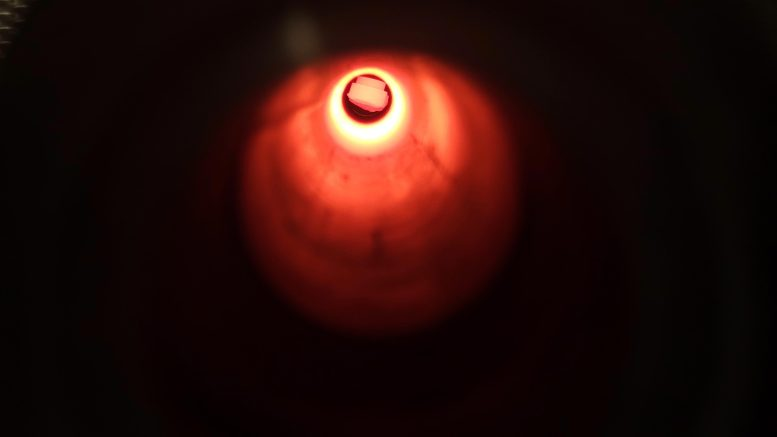

To test this, researchers used a regolith simulant designed to mimic the material found at Gale Crater on Mars. The simulant was placed in a chamber that recreated the low-pressure surface environment of Mars and then heated to high temperatures. The results were promising. At around 1000°C, the team observed the formation of pure iron. At higher temperatures, near 1400°C, silicon-iron alloys were produced.

When the temperature was high enough, the metals combined into a single large droplet, which could be separated from liquid slag in the same way it’s done on Earth. This proves that metal extraction on Mars can work using processes similar to those used in terrestrial foundries.

The project is being led by Professor Akbar Rhamdhani, an astrometallurgist at Swinburne, along with Dr. Deddy Nababan, a CSIRO postdoctoral fellow and Swinburne graduate. They are also collaborating with Dr. Mark Pownceby of CSIRO. Their focus is not only on extracting metals but also on doing so with zero waste, ensuring byproducts of the process can be repurposed into useful items for settlement construction.

The importance of ISRU in space exploration cannot be overstated. Every kilogram of material launched into space adds cost and complexity to missions. Even though launch costs are gradually falling, the scale of resources needed for long-term human presence on Mars remains enormous.

Progress has already been demonstrated in this area. For example, NASA’s MOXIE experiment, which flew aboard the Perseverance rover, successfully generated oxygen directly from Mars’ carbon dioxide-rich atmosphere. This was the first real-world proof of ISRU on Mars. Now, metal production is being explored as the next major step.

If successful at scale, Mars-made alloys could become essential building blocks for habitats, research facilities, and machinery for excavation and construction. However, challenges remain. The research team notes that it is still unclear how well these alloys would hold up over time in the actual Martian environment, and more work is needed to ensure the process can be replicated under real conditions on the planet’s surface.

In addition to conducting experiments, Swinburne and CSIRO are also working on building global interest in astrometallurgy. Recently, Professor Rhamdhani, Dr. Nababan, and another Swinburne alum, Dr. Matt Shaw of CSIRO, delivered a four-day workshop on astrometallurgy in South Korea, which received encouraging feedback.

Interest in this field is growing as governments, space agencies, and private organizations turn their attention toward long-term Mars exploration. Experts from diverse disciplines such as mining, engineering, and geology will be required to make sustainable Mars colonization possible.

The benefits of this research extend beyond space. By pushing the boundaries of metallurgy under extreme conditions, scientists also hope to discover methods that can make industrial processes more efficient here on Earth.

Ultimately, the vision is that techniques for extracting and using metals from Martian soil will not only support future colonies but also deliver innovations that improve life at home.

TLDR

Researchers from Swinburne and CSIRO have successfully produced iron under Mars-like conditions using regolith simulant. This breakthrough in astrometallurgy could enable building materials to be made directly on Mars, reducing reliance on costly Earth shipments and supporting future colonies.