University of Minnesota Scientists Unlock New Possibilities in Nanomaterials Through Controlled Defects

Researchers at the University of Minnesota Twin Cities have found a remarkable way to intentionally create and control tiny structural flaws within ultra-thin materials. These flaws, known as extended defects, could redefine how nanomaterials behave—opening the door to a whole new range of technologies in electronics, optics, and energy systems.

The research team, led by Professor K. Andre Mkhoyan from the Department of Chemical Engineering and Materials Science, demonstrated that by carefully designing where and how these defects appear, materials can be engineered to display entirely new physical and electronic properties. The study, published in Nature Communications, represents a major step in the growing field of defect engineering—where imperfections are not mistakes, but powerful tools.

Understanding Extended Defects

Extended defects are atomic-scale disruptions that run through a material’s crystal structure. Unlike isolated point defects—such as missing or substituted atoms—extended defects stretch across the material, forming dislocations, stacking faults, or planar boundaries. They can significantly alter how a material behaves, affecting its strength, conductivity, or even optical transparency.

In most traditional material science, defects are seen as problems that weaken performance. But the University of Minnesota team has turned that idea on its head. Instead of trying to eliminate these irregularities, they have learned how to create and position them deliberately, using them as design elements at the nanoscale.

The Breakthrough Approach

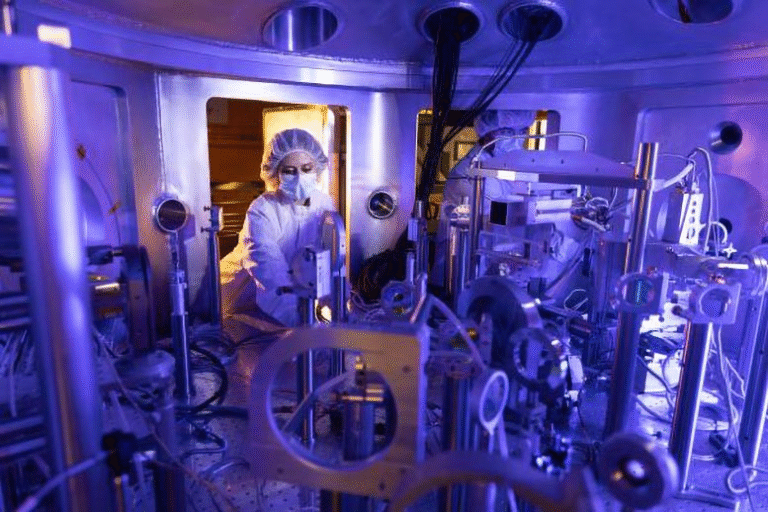

The research focused on ultra-thin perovskite oxide films, specifically barium stannate (BaSnO₃) and strontium stannate (SrSnO₃)—materials already known for their transparency and high electron mobility. To engineer defects, the team used a method called nanoscale substrate patterning.

In simple terms, they first etched tiny patterns on the surface of the substrate—using a focused ion beam (FIB)—before growing the thin film on top. These surface patterns acted as defect seeds, encouraging the formation of specific types of extended defects as the material grew layer by layer.

The result was astounding: patterned areas showed a defect density up to 1,000 times higher than unpatterned regions. This level of precision means scientists can now design a single material with different defect densities and types in specific zones, effectively tailoring its behavior across the surface.

For example, a film could have one region rich in dislocations—offering unique electrical properties—and another area nearly defect-free for strength or transparency. This ability to mix and match defect environments within the same film could revolutionize how materials are built for next-generation devices.

Tools and Techniques

To confirm their results, the researchers employed advanced microscopy techniques, including high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) and energy-dispersive X-ray spectroscopy (STEM-EDX). These tools allowed them to visualize the defects at the atomic level, mapping how the dislocations and planar faults propagated through the film’s thickness.

They discovered that these extended defects traverse the material vertically—meaning they span the entire thin film while occupying a very small volume. This unique geometry makes it possible to exploit both the properties of the defect itself and the surrounding pristine material simultaneously.

The study involved a multidisciplinary team from the University of Minnesota, including Supriya Ghosh (first author), Jay Shah, Silu Guo, Mayank Tanwar, Donghwan Kim, Sreejith Nair, Matthew Neurock, Turan Birol, and Bharat Jalan, as well as Fengdeng Liu from the Department of Electrical and Computer Engineering.

Why This Matters

This breakthrough gives scientists a new degree of control over material functionality. Defect engineering is not a completely new concept, but what sets this study apart is the precision and predictability of the method. Researchers can now fine-tune where defects appear, how dense they are, and what type they take—all at the nanoscale.

Such control could have wide-ranging applications:

- Electronics: Designing semiconductors with custom defect zones could enable faster or more energy-efficient devices.

- Optoelectronics: Extended defects can modify how materials interact with light, leading to new kinds of sensors or transparent conductors.

- Energy Materials: In catalysts or battery electrodes, defects often act as active sites that improve performance. Patterning them deliberately could yield major gains in efficiency.

- Quantum and Functional Materials: In emerging quantum materials, defect structures can alter magnetic and electronic properties in ways that might be harnessed for new computing architectures.

By combining defect control with existing methods like strain engineering and chemical doping, scientists gain another powerful way to shape how materials behave.

Challenges and Future Directions

While promising, this approach is still at the research stage. Focused ion beam patterning, though precise, is a relatively slow and expensive process, which limits scalability for large-scale production. Researchers hope to adapt this concept to lithographic or self-assembly techniques that could produce similar effects more economically.

Additionally, not all materials will respond the same way. The study demonstrated success with perovskite oxides, but it remains to be seen whether the method can be generalized to semiconductors, metals, or 2D materials like graphene and transition metal dichalcogenides.

Another challenge lies in balancing the benefits and drawbacks of high defect densities. While defects can enhance certain functionalities, they can also reduce carrier mobility or weaken mechanical strength. Future research will need to explore where the “sweet spot” lies for each application.

Still, this work represents a paradigm shift in how we think about materials. Instead of fighting defects, researchers can now design them with purpose, just like any other structural or compositional feature.

A Deeper Look at Defect Engineering

Defect engineering has become one of the most exciting trends in modern materials science. At the atomic scale, imperfections can dramatically change how electrons, phonons, and photons move through a material. For instance:

- In semiconductors, controlled defects are used to create p-n junctions that form the basis of transistors and solar cells.

- In metal oxides, oxygen vacancies can enhance ionic conductivity, making them useful for fuel cells.

- In quantum materials, dislocations can pin magnetic vortices or host exotic states like topological edge currents.

By understanding and manipulating defects, scientists effectively gain another “dial” for controlling a material’s performance—alongside composition and structure.

The University of Minnesota’s work stands out because it moves this control to the nanoscale patterning level. That means we could one day design a film where each micrometer behaves differently, depending on its engineered defect structure. It’s like turning materials into programmable platforms.

The Big Picture

In the long run, this technique could lead to materials that behave in entirely new ways—films whose conductivity, magnetism, or transparency can be customized by design, not by chance.

Imagine electronics where every component is made from the same base material, but with different defect “programs” written into it. Or solar cells that funnel charge through defect-rich highways while remaining transparent and strong elsewhere.

That’s the potential of this discovery. It’s not just about fixing flaws—it’s about using flaws as a feature.

Research Reference:

Defect engineering in BaSnO₃ and SrSnO₃ thin films through nanoscale substrate patterning – Nature Communications (2025)