AI Model Discovers High-Performing Battery Electrolytes Using Only 58 Data Points

Researchers at the University of Chicago’s Pritzker School of Molecular Engineering have developed a new active learning AI model that identified four high-performing battery electrolyte solvents after starting with just 58 experimental data points. This work focuses on anode-free lithium-metal batteries, a promising next-generation technology known for high energy density but challenging cycle life. The project demonstrates how AI can speed up discovery in fields where experiments are slow, expensive, and historically dependent on large datasets.

How the Project Started

The core challenge the team tackled is the lack of large, high-quality experimental datasets for emerging battery chemistries. Traditional AI models for material discovery often require millions of data points, which is impossible for new chemistries because each battery experiment can take weeks or months.

Instead of waiting for years of experiments, the researchers built an active learning model capable of searching a virtual chemical space of around one million electrolyte candidates. These candidates were primarily combinations of solvents and lithium salts drawn from major chemical databases such as PubChem and eMolecules.

What makes this study stand out is that the AI wasn’t trained purely on computational simulations. The model received real experimental results as feedback, making its predictions more grounded in practical performance.

The Active Learning Approach

The team used an AI-driven active learning loop, which works in repeated cycles:

- Start with a small dataset of 58 real electrolyte performance results.

- Train multiple Gaussian Process Regression (GPR) models using different kernels.

- Combine their outputs using Bayesian Model Averaging to handle uncertainty.

- Search the space of one million possible electrolyte solvents.

- Select around 10 promising candidates per cycle using acquisition functions that balance exploration and exploitation.

- Test these suggestions in real Cu‖LiFePO₄ anode-free cells.

- Add the new results back to the training set and repeat.

The researchers completed seven full active learning campaigns, testing roughly 70 electrolytes in total before the model converged on four top performers.

Why Using Experiments Matters

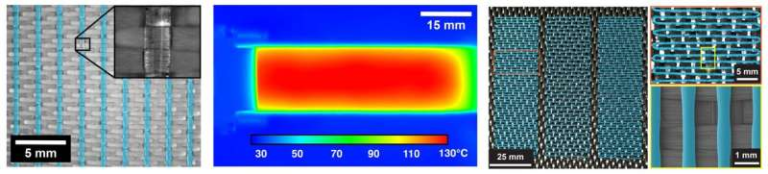

Many prior AI-for-materials studies used computational proxies, such as simulated electrochemical properties. But computational metrics do not always reflect real-world behavior inside a working battery cell. In contrast, this team insisted on using actual battery cycling performance as the output data.

The metric they focused on was capacity retention, a direct measure of how much energy a battery can hold after repeated charge-discharge cycles. This is especially critical in anode-free lithium-metal batteries, where cycle life has historically been a barrier.

By validating every AI suggestion experimentally, the researchers ensured the AI’s predictions stayed aligned with practical performance instead of drifting into unrealistic chemical spaces.

The Four New Electrolytes

From the seven training loops, the AI pinpointed four previously unexplored electrolyte solvents that performed on par with some of the best state-of-the-art electrolytes used today. These solvents were repeatedly selected by the acquisition function and consistently showed strong capacity retention in lab testing.

Although the specific chemical names are in the technical paper, their common characteristics provide insight:

- They were mostly ether-based solvents, which are known for stabilizing lithium metal interfaces.

- They formed improved solid-electrolyte interphases (SEI) on the copper current collector.

- They supported smoother lithium plating and stripping, which is crucial in anode-free designs.

- Their solvation structures facilitated better ionic transport and reduced unwanted reactions.

Why This Matters for Battery Development

Anode-free lithium-metal batteries could dramatically increase energy density for electric vehicles, drones, consumer electronics, and aerospace applications. But the chemistry is notoriously unstable because lithium must plate onto a bare copper current collector during every cycle.

Electrolytes play a central role in stabilizing lithium deposition, suppressing dendrites, and maintaining cycle life. Discovering new, optimized solvents is essential—but the chemical design space is massive, with estimates around 10⁶⁰ possible molecules.

This is where the new AI workflow becomes powerful. Instead of screening millions of candidates manually, the model narrows the space intelligently using uncertainty estimates, real experiments, and Bayesian learning.

How This Fits Into the Future of Battery AI

The researchers are already thinking ahead. One key next step is moving from predictive models to generative AI, where the system invents entirely new molecules that don’t exist in any database. This could open the door to chemical innovations that human researchers may never have considered.

Another major future goal is multi-objective optimization. Right now, the model focuses on a single performance metric—cycle life—but commercial electrolytes also need to excel in:

- Safety

- Ionic conductivity

- Thermal stability

- Cost and manufacturability

- Compatibility with other battery components

Building models that evaluate many criteria at once could drastically accelerate discovery of commercial-ready electrolytes.

Why Small-Data AI Is Becoming Important

Battery research isn’t the only field with limited datasets. Many areas of materials science, chemistry, and physics suffer from the same problem: experiments are slow and expensive, and high-quality datasets are tiny.

This project shows that you don’t always need big data. By combining:

- small experimental datasets

- Bayesian modelling

- active learning

- and real-world testing

it’s possible to achieve big-data-level insights even in small-data environments.

This approach is likely to influence work in catalysts, polymers, superconductors, semiconductors, and many other domains.

Additional Context: What Are Anode-Free Lithium-Metal Batteries?

To help readers understand the significance of the research, here’s a quick breakdown of what makes these batteries interesting.

What Makes Them Different?

In conventional lithium-ion batteries, the anode is typically made of graphite. In lithium-metal batteries, the anode is lithium metal itself, offering much higher energy density.

Anode-free designs take this a step further:

- There is no anode material at all during manufacturing.

- Lithium plates directly onto a thin copper current collector during the first charge.

This enables:

- Lower weight

- Lower manufacturing cost

- Higher energy density

But it also introduces serious challenges.

Why Are Electrolytes So Important?

Lithium can deposit unevenly, forming dendrites, consuming lithium inventory, and causing rapid capacity fade. The electrolyte determines how lithium ions behave during plating/stripping and how protective SEI layers form.

A better electrolyte can directly lead to:

- smoother lithium deposition

- higher cycle life

- safer operation

- more stable SEI layers

- reduced side reactions

This is why discovering new electrolyte solvents is such a big deal—and why using AI to do it quickly is exciting.

The Broader Impact on Materials Discovery

This study demonstrates a major shift in scientific research. Instead of relying solely on human intuition or brute-force experiments, scientists can now work with AI partners that:

- explore large chemical spaces

- quantify their own uncertainty

- recommend the next best experiment

- and improve continuously

By using this active learning strategy, researchers can massively reduce the cost and time of discovering new materials.

This could speed up progress in:

- solid-state batteries

- sodium-ion batteries

- hydrogen storage materials

- carbon capture sorbents

- catalysts for clean energy

- photovoltaics

- polymer design

The implications extend far beyond just batteries.

Research Paper Reference

Active learning accelerates electrolyte solvent screening for anode-free lithium metal batteries

https://doi.org/10.1038/s41467-025-63303-7