Batteries Slowly Wear Out Because They “Breathe,” and Scientists Now Know Why

Modern life runs on batteries. From smartphones and wireless earbuds to electric vehicles and large-scale energy storage systems, rechargeable batteries are everywhere. Yet no matter how advanced they become, one familiar problem refuses to go away: batteries gradually lose capacity and performance over time. Now, a new study has identified a key reason behind this decline, and it has everything to do with how batteries physically change shape as they are used.

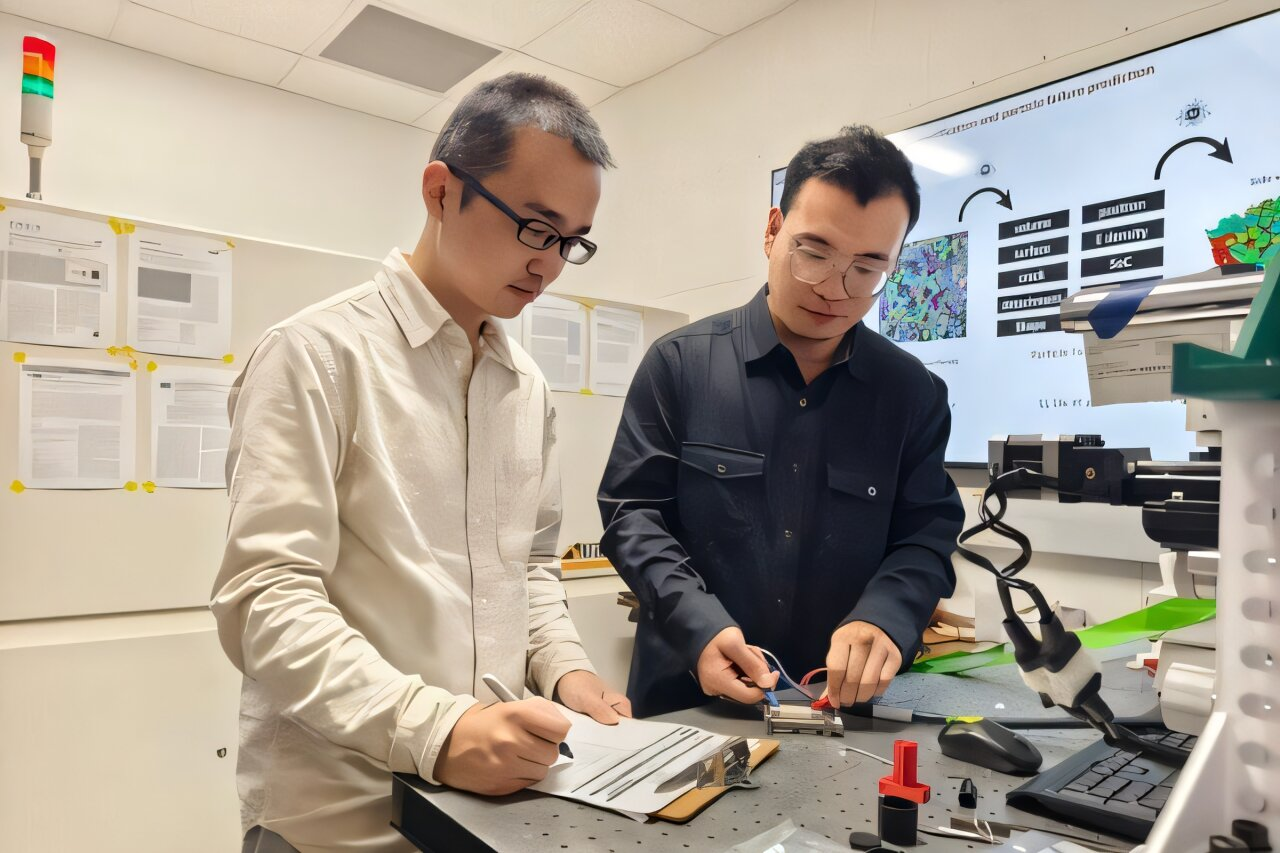

Researchers from The University of Texas at Austin, Northeastern University, Stanford University, and Argonne National Laboratory have found that batteries experience a subtle but constant cycle of expansion and contraction during charging and discharging. This motion is so consistent that scientists describe it as batteries “breathing.” While this breathing may sound harmless, it turns out to be one of the main drivers of long-term battery deterioration.

The findings were published in the prestigious journal Science, marking an important step toward building longer-lasting, more reliable, and higher-performance batteries.

What Does It Mean When a Battery “Breathes”?

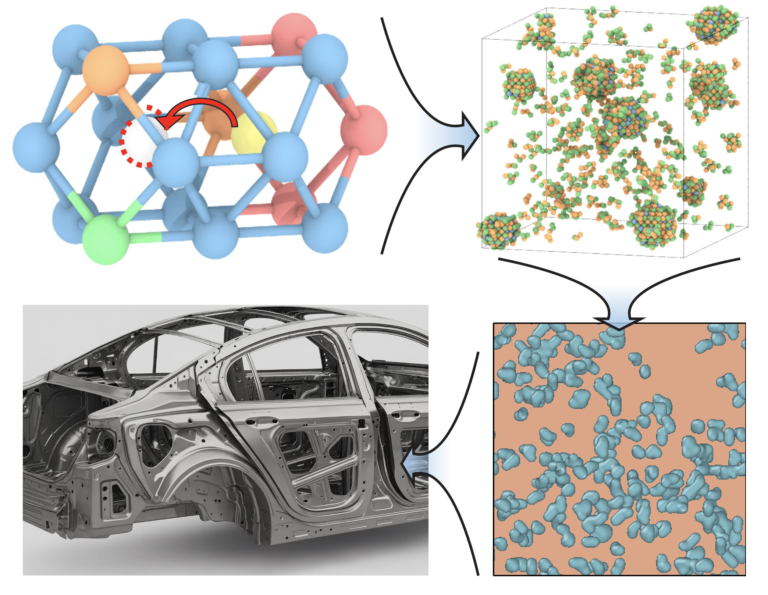

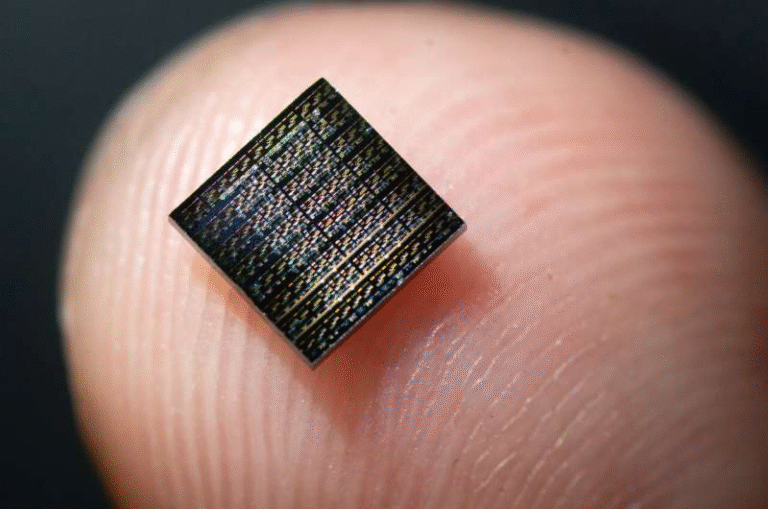

At the heart of every rechargeable battery is a chemical process in which ions move back and forth between electrodes. In lithium-ion batteries, lithium ions shuttle between the cathode and anode during charging and discharging. This movement causes the materials inside the battery to expand slightly when ions enter and contract when ions leave.

Individually, these changes are incredibly small—often invisible without advanced instruments. But batteries go through thousands of charge and discharge cycles over their lifetime. Over time, these repeated expansions and contractions create mechanical stress within the battery’s internal structure.

Scientists refer to this combined chemical and mechanical damage as chemomechanical degradation. It is not caused by a single dramatic failure, but by tiny, accumulated distortions that slowly weaken the battery from the inside out.

How Repeated Strain Leads to Battery Failure

One of the major breakthroughs of this study was showing that battery damage does not occur evenly. Instead, stress builds up unevenly across the electrode, creating what the researchers call strain cascades.

A strain cascade begins when stress develops in one region of the electrode and then spreads to neighboring areas. Because a battery electrode is made up of hundreds of thousands of microscopic particles, each with its own shape, size, and orientation, they do not all react to charging in the same way.

Some particles move rapidly and dramatically when lithium ions flow in or out, while others barely shift at all. This uneven behavior creates localized stress points, which can eventually lead to cracking, warping, or loss of electrical connectivity inside the electrode. Over many cycles, these small failures add up, reducing the battery’s ability to store and deliver energy.

The researchers observed that this damage is often irreversible. Once particles deform or fracture, the battery cannot fully recover its original structure, even if operating conditions improve.

Seeing Inside a Working Battery in Real Time

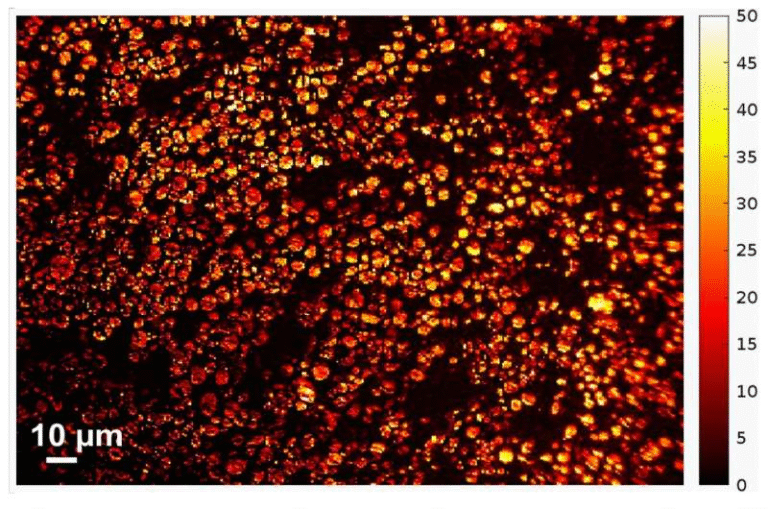

To uncover these hidden processes, the research team relied on advanced real-time imaging techniques that allow scientists to observe battery materials as they operate.

Two key tools played a central role:

- Operando transmission X-ray microscopy (TXM), which provides high-resolution images of electrode particles during active charging and discharging

- 3D X-ray laminography, which captures three-dimensional views of internal structures without dismantling the battery

Using these techniques, the researchers were able to track how individual particles move, strain, and interact under real operating conditions. This approach revealed details that traditional post-mortem battery analysis often misses.

Interestingly, the team first noticed this breathing-related behavior while studying commercial wireless earbuds, showing that these effects are not limited to laboratory prototypes but occur in everyday consumer electronics.

Why This Discovery Matters for Battery Technology

Battery degradation has long been a puzzle for engineers and scientists. While chemical reactions, side products, and temperature effects are well known contributors, this study highlights mechanical strain as an equally critical factor.

By identifying how strain forms and spreads, researchers now have a clearer roadmap for improving battery durability. Understanding these mechanics could help engineers:

- Design electrode materials that better tolerate expansion and contraction

- Optimize particle size, shape, and arrangement to reduce uneven stress

- Apply controlled external pressure to battery cells to counteract internal strain

- Develop predictive models that link chemical reactions with mechanical behavior

Rather than treating mechanical damage as an unavoidable side effect, future batteries may be intentionally engineered to manage and distribute strain more evenly.

The Role of Electrode Design in Battery Lifespan

Electrode design plays a central role in how strain develops. Layered intercalation cathodes, which are common in lithium-ion batteries, are particularly sensitive to repeated volume changes. If particles expand in different directions or at different rates, internal stress rises quickly.

This study shows that even when the overall chemical composition remains stable, mechanical mismatches at the microscopic level can still drive performance loss. That insight helps explain why some batteries degrade faster than expected, even when operated within recommended limits.

The researchers emphasize that understanding the relationship between electrode architecture and stress response is essential for pushing battery technology forward.

Broader Implications for Electric Vehicles and Energy Storage

The implications of this work extend far beyond smartphones and earbuds. Electric vehicles, grid-scale energy storage systems, and renewable energy infrastructure all depend on batteries that can endure heavy use over many years.

Even small improvements in battery lifespan can translate into:

- Lower replacement costs

- Reduced environmental impact

- Improved safety and reliability

- Better overall performance

By targeting chemomechanical degradation directly, manufacturers could significantly extend battery life without needing entirely new chemistries.

What’s Next for This Line of Research?

The research team plans to continue exploring the complex interactions between chemical reactions and mechanical forces inside batteries. One of their next goals is to develop theoretical and computational models that can predict strain behavior before a battery is even built.

Such models could help engineers test new designs virtually, saving time and resources while accelerating innovation.

Ultimately, this work brings scientists closer to batteries that are not only more powerful but also far more durable, capable of surviving years of repeated use without significant performance loss.

Extra Context: Why Batteries Age Even When Used Carefully

Many people assume batteries fail mainly due to overcharging, extreme temperatures, or misuse. While those factors do matter, this research highlights a more subtle truth: even ideal usage conditions cannot completely eliminate internal mechanical stress.

Every charge cycle, no matter how gentle, causes a battery to breathe. Over time, that breathing leaves a physical imprint. Recognizing this helps set realistic expectations for battery life and underscores why engineering solutions—not just user habits—are essential.

Research Reference

Electrode strain dynamics in layered intercalation battery cathodes

Science (2025)

https://doi.org/10.1126/science.aea2763