Coal Tailings Could Solve the United States’ Growing Need for Rare Earth Elements

Rare earth elements play a quiet but critical role in modern life. They are essential for magnets, electronics, batteries, renewable energy technologies, medical imaging, and catalysts used in chemical reactions. Despite the name, these elements are not especially rare in the Earth’s crust. The real challenge lies in finding economical and environmentally acceptable ways to extract and refine them. For decades, this difficulty has shaped global supply chains—and left the United States increasingly dependent on foreign sources.

New research from Northeastern University suggests that an unlikely material could help change this situation: coal tailings, the piles of leftover soil and rock produced during coal mining. According to the study, these massive waste deposits may hold significant quantities of rare earth elements, and a newly developed extraction method could unlock them far more efficiently than before.

Why Rare Earth Elements Matter So Much

Rare earth elements, often shortened to REEs, are a group of 17 metallic elements that are indispensable to modern technology. They are used in high-performance magnets, electric vehicle motors, wind turbines, smartphones, laptops, medical scanners, and advanced military systems. Although these elements are relatively abundant in nature, they are usually found mixed with other minerals, sometimes alongside radioactive materials, which makes extraction complex and costly.

Since the 1980s, a global competition has been underway to control the rare earth market. Over time, China has emerged as the dominant force, not because it has uniquely rich deposits, but because it invested heavily in mining, refining, and processing infrastructure. Today, China controls an estimated 90 percent of the global rare earth supply, giving it significant economic and geopolitical leverage.

Looking Beyond Traditional Sources

In the United States, rare earth elements are often recovered as byproducts of other mining activities. One well-known source is coal fly ash, the powdery residue left after coal is burned. Fly ash has been studied extensively and is already known to contain recoverable rare earths.

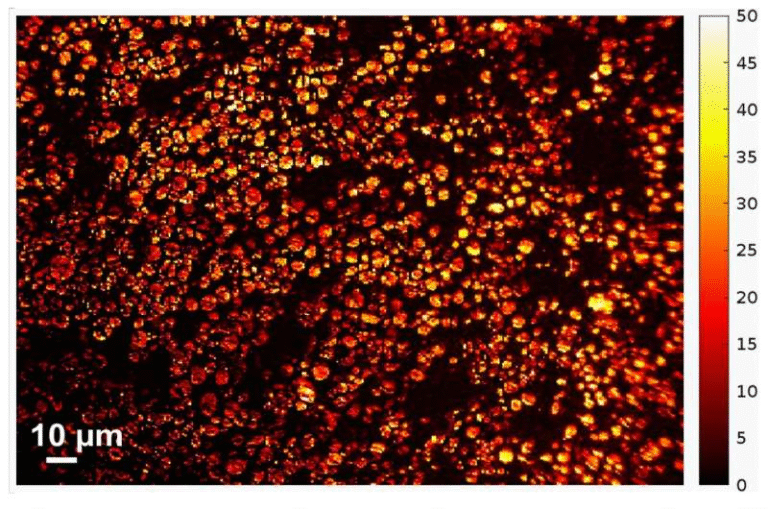

Coal tailings, however, have received far less attention. These tailings are the unwanted remnants of coal mining, often piled into massive heaps near old or active mines. They still contain large amounts of organic material, making them harder to process than fly ash. Because fly ash has been easier to work with, coal tailings have largely been ignored—despite the sheer volume scattered across the country.

A New Extraction Method Shows Promise

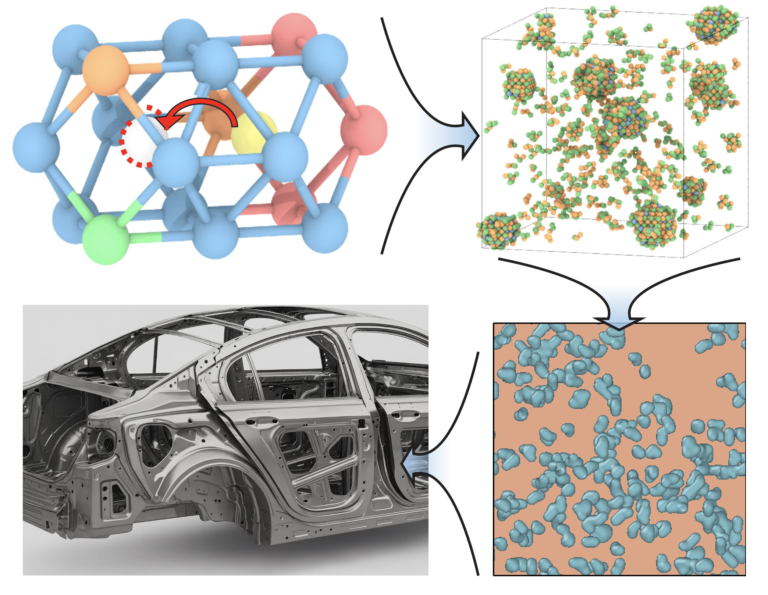

The Northeastern University research team developed a method that significantly improves rare earth recovery from coal tailings. The process begins with pretreating the tailings using sodium hydroxide, commonly known as lye, mixed with water. This step alters the chemical and physical structure of the material.

Next, the treated tailings are exposed to nitric acid, but with a crucial twist: the reaction temperature is carefully controlled using a specialized microwave reactor. This reactor allows the researchers to precisely heat the material, triggering structural changes that make rare earth elements easier to extract.

The results were striking. The team achieved two to three times higher extraction efficiency compared to standard methods previously used on coal byproducts. This improvement comes from the combined effect of chemical treatment and controlled thermal stimulation, which reshapes the solid structure of the tailings and releases valuable elements trapped inside.

What’s Actually Inside Coal Tailings?

The rare earth elements recovered from coal tailings have real industrial value. One notable example is neodymium, which turned out to be the third-most abundant rare earth element found in the tested tailings. Neodymium is essential for high-strength permanent magnets, which are widely used in electric vehicles, wind turbines, and advanced electronics.

Coal tailings may also contain other useful materials, including magnesium, iron, and even radioactive elements. While this complicates processing, it also means that a well-designed industrial operation could potentially extract multiple valuable resources from the same waste material.

The Scale of the Opportunity in the U.S.

The potential scale of this resource is enormous. In Pennsylvania alone, where the tailings used in the study were collected, there are an estimated 2 billion tons of coal tailings. Across the United States, countless abandoned and inactive mines have left behind similar deposits.

These tailings represent a domestic resource that already exists, does not require new mining, and could help reduce reliance on foreign rare earth supplies. From a national security and economic standpoint, that makes them particularly attractive.

The Barriers to Widespread Adoption

Despite the promise, major obstacles remain. One of the most significant challenges is technology cost. Microwave reactors capable of operating at the scale needed for industrial extraction are expensive and not widely available. Scaling up from laboratory experiments to full-scale operations would require substantial investment.

Another issue is geological variability. Coal tailings differ widely depending on where they come from. Their mineral composition can change from region to region, and even from one mine to another. This means the extraction process may need to be customized for different locations, adding complexity and cost.

There are also environmental and regulatory concerns. The process involves strong chemicals like lye and nitric acid, which produce liquid waste that must be safely managed. Any large-scale operation would need strict environmental controls to prevent contamination of soil and water.

Rare Earth Security and Global Competition

China’s dominance of the rare earth market is not accidental. By consolidating its mining operations into a small number of large, mostly state-owned companies, China created economies of scale that drove down prices and pushed competitors out of business elsewhere. This strategy left other countries, including the United States, struggling to maintain viable domestic industries.

As demand for rare earth elements continues to rise—driven by clean energy technologies, electric vehicles, and advanced electronics—there is growing urgency to find alternative and reliable sources. Coal tailings could become one part of a broader strategy to rebuild domestic supply chains.

Understanding Rare Earth Elements Beyond the Headlines

It’s worth noting that rare earth elements are often misunderstood. They are not rare in terms of availability, but rarely found in concentrated, easily extractable forms. Mining them directly can cause significant environmental damage, which is why secondary sources like coal waste are drawing attention.

Using coal tailings also offers a potential environmental benefit. These waste piles can pose long-term risks, including acid mine drainage and land degradation. Extracting valuable materials from them could help reduce their environmental footprint while generating economic value.

A Cautious but Optimistic Outlook

The Northeastern University study does not claim to have solved the rare earth problem overnight. Instead, it offers a technically sound and scientifically promising approach that could complement other efforts to secure critical minerals. Much work remains to determine whether the method can be scaled safely, economically, and sustainably.

Still, the idea that decades-old mining waste could help supply the materials needed for tomorrow’s technologies is both practical and intriguing. Coal tailings, long viewed as a liability, may yet become an unexpected asset in the United States’ push for rare earth independence.

Research paper:

https://pubs.acs.org/doi/10.1021/acs.est.5c05711