Corrugated OLED Panel Design Dramatically Improves Lighting Lifespan and Efficiency

Organic light-emitting diodes, better known as OLEDs, are everywhere today—powering the vivid displays on smartphones, TVs, and wearable devices. But when it comes to using OLEDs for room lighting, they’ve always faced a stubborn problem: they degrade too quickly when pushed to the brightness levels needed to illuminate indoor spaces. A new study published in Nature Communications now shows a promising way forward. By building OLEDs on a corrugated, three-dimensional surface instead of a flat one, researchers have significantly extended their lifespan while also boosting efficiency.

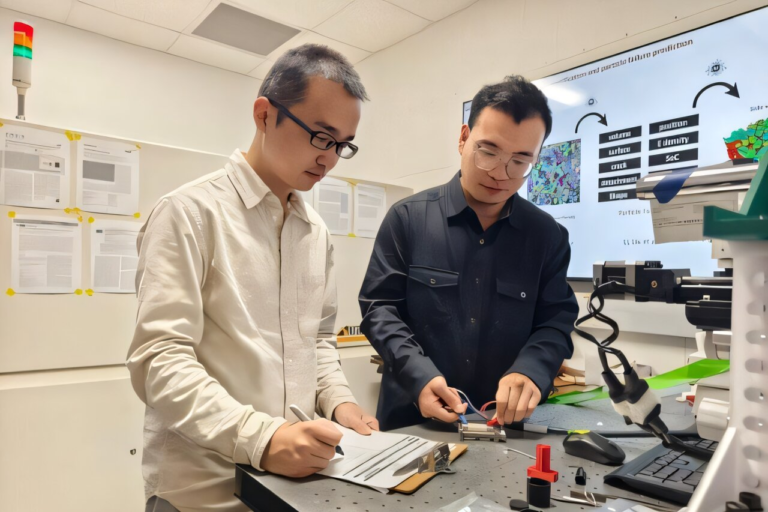

The work was led by researchers at the University of Michigan, in collaboration with OLEDWorks and The Pennsylvania State University, and it demonstrates that sometimes a change in structure, rather than materials, can make a major difference.

Why OLED Lighting Has Struggled Until Now

OLEDs are fundamentally different from traditional LEDs. Instead of using rigid, inorganic materials like gallium nitride, OLEDs rely on thin organic layers that emit light when electricity passes through them. This gives OLEDs some unique advantages: they are ultra-thin, flexible, and capable of producing large, evenly glowing panels.

However, these same organic materials are also more sensitive to high current densities. To produce the brightness needed for room lighting, conventional flat OLED panels must be driven hard, which accelerates chemical degradation. Over time, this leads to fading, especially in blue OLEDs, which are known to degrade the fastest. This tradeoff between brightness, efficiency, and longevity has limited OLEDs mostly to displays rather than general lighting.

Moving From Flat to Three-Dimensional OLEDs

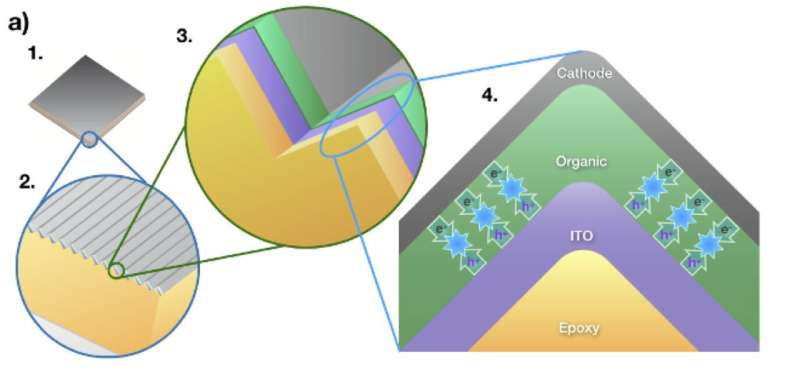

The new research tackles this issue by rethinking the basic geometry of an OLED panel. Instead of depositing OLED layers onto a perfectly flat surface, the team built them on a corrugated surface made of microscopic ridges.

These ridges are tiny—only about one-tenth of a millimeter tall—so small that the panel still appears flat to the naked eye. But at the microscopic level, this texture changes everything. The corrugation increases the total surface area available for light emission within the same panel footprint.

By packing more emitting area into the same space, the OLED can produce the same total amount of light while operating each unit at a lower brightness. Lower brightness at the device level means lower current density, which directly translates to slower degradation and longer lifespan.

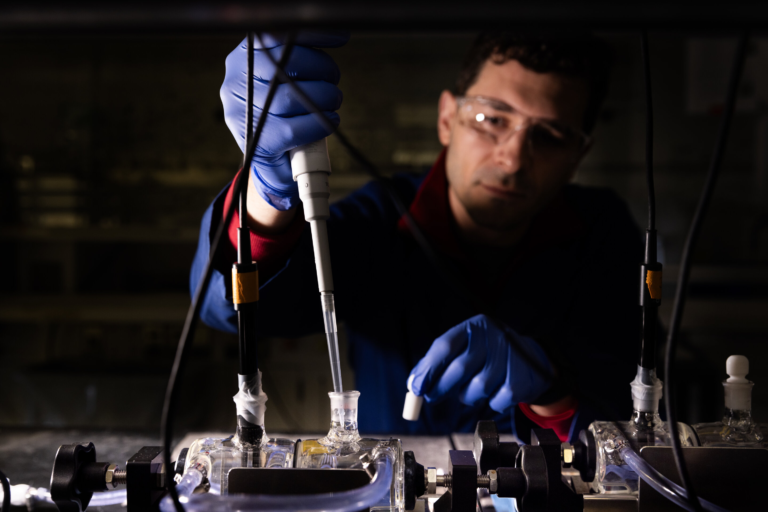

How the Corrugated OLED Panels Were Made

To build the prototype panels, the University of Michigan team first created the corrugated surface by molding tiny triangular ridges into a thin layer of epoxy on top of a glass sheet. Although the ridges are only around 100 micrometers high, they are massive compared to the OLED layers themselves, which are typically thousands of times thinner than a human hair.

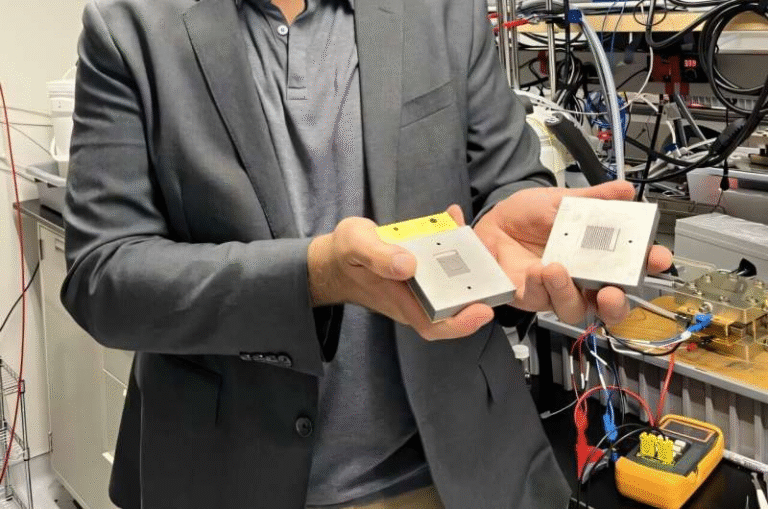

Once the textured glass was prepared, it was shipped to OLEDWorks, where engineers deposited the functional OLED layers. These included a layer of soft, flexible organic emitting material sandwiched between a transparent indium tin oxide electrode and a reflective metal electrode.

Because the height of each ridge is comparable to the width of its base, the OLED layers form a high aspect ratio structure, meaning there is significantly more emitting area along the ridge facets than on a flat surface.

Lifetime Improvements: The 2.7× Breakthrough

To evaluate performance, the researchers compared corrugated OLED panels with traditional flat panels under the same operating conditions. Both green and blue OLEDs were tested, but special attention was given to blue devices because they are typically the most fragile.

The results were striking. In fade testing, which measures how long it takes for brightness to drop to a defined level, the corrugated blue OLEDs lasted 2.7 times longer than their flat counterparts when operated at the same current. This dramatic improvement was directly linked to the reduced current passing through each unit area of the corrugated OLED.

In simpler terms, the OLEDs weren’t working as hard to produce the same amount of light—and that made all the difference.

A Significant Boost in Efficiency as Well

Longevity wasn’t the only improvement. Using a combination of analytical calculations and ray-tracing simulations, the research team found that corrugated OLEDs also achieved about 40% higher external light extraction efficiency.

Light extraction efficiency refers to how much of the light generated inside the OLED actually escapes the device instead of being trapped by internal reflections. Because the internal OLED layers were identical in both designs, the researchers concluded that the corrugated geometry helps light bounce out more effectively, reducing losses that are common in flat OLED panels.

This means corrugated OLEDs deliver more light per unit of electricity, further strengthening their case as a viable lighting technology.

Why Geometry Matters More Than Perfection Here

Traditionally, OLED manufacturing places enormous emphasis on creating perfectly smooth, pristine surfaces, as even small imperfections can disrupt thin organic layers. One surprising finding from this study is that the corrugated OLEDs performed well despite tiny microstructural imperfections.

This challenges a long-held assumption in OLED fabrication and suggests that embracing the third dimension may open up new design freedoms without sacrificing performance.

What This Means for White OLED Lighting

The study focused on blue and green OLEDs, but the ultimate goal is full-spectrum white OLED lighting, which typically combines red, green, and blue emitters stacked together. The researchers plan to apply the same corrugated approach to these multi-layer designs.

If successful, this could lead to high-quality white OLED panels that are efficient, long-lasting, and suitable for real-world lighting applications such as architectural lighting, decorative panels, and flexible luminaires.

How OLED Lighting Compares to Traditional LEDs

Inorganic LEDs already dominate indoor lighting because they are efficient and long-lived. However, OLEDs offer something LEDs cannot: large, diffuse light sources that can be integrated into walls, ceilings, furniture, or curved surfaces.

With improved lifespan and efficiency, OLEDs could complement traditional LEDs rather than replace them—especially in applications where design, softness of light, and form factor matter more than sheer brightness.

A Practical Path Toward Commercial Adoption

One of the most important aspects of this work is that it doesn’t rely on exotic new materials or radically different manufacturing techniques. The corrugated OLEDs can be made using existing OLED deposition processes, making the approach far more practical for scaling and commercialization.

By solving a longstanding challenge through structural innovation, this research points to a realistic path for bringing durable, energy-efficient OLED lighting products to market.

Research Reference

High aspect ratio organic light-emitting diodes – Nature Communications (2025)

https://www.nature.com/articles/s41467-025-67312-4