CU Boulder Engineers Create Real-Time Imaging Technology to Improve Desalination Membrane Performance

Engineers at the University of Colorado Boulder have developed a powerful new imaging technique that could significantly improve how desalination plants operate around the world. The research introduces a way to observe membrane fouling in real time, offering desalination operators a much clearer picture of what happens inside filtration systems as they run. By using an advanced laser-based method called stimulated Raman scattering (SRS), the team can simultaneously visualize and chemically identify materials that build up on desalination membranes—something that has not been possible before.

This breakthrough comes at a critical moment. Around 55% of the global population experiences water scarcity for at least one month every year, and projections suggest that number could rise to 66% by the end of this century. As freshwater resources continue to shrink, desalination is becoming an essential tool for meeting global water demand. However, the technology is not without challenges, and membrane fouling remains one of the biggest obstacles to making desalination more efficient and sustainable.

Why Reverse Osmosis Membranes Matter So Much

Most modern desalination plants rely on reverse osmosis (RO), a process that uses thin polymer membranes to separate salt and other contaminants from seawater. These membranes act as selective barriers, allowing water molecules to pass through while blocking dissolved salts, minerals, and microorganisms.

Today, about 80% of the world’s desalination facilities use reverse osmosis, which makes the health and performance of RO membranes incredibly important. When membranes are clean and functioning well, plants can produce fresh water efficiently. When membranes become fouled, performance drops quickly.

Membrane fouling occurs when salts, minerals, organic matter, or biological organisms accumulate on the membrane surface. Over time, this buildup restricts water flow, increases energy consumption, and raises operating costs. Fouled membranes also require frequent chemical cleaning or replacement, both of which are expensive and environmentally taxing.

Despite years of research, early detection of fouling has remained a major challenge. Most existing monitoring methods only provide indirect signals—such as pressure changes or flow reduction—rather than direct, visual evidence of what is forming on the membrane.

How Stimulated Raman Scattering Changes the Game

The CU Boulder team tackled this problem using stimulated Raman scattering microscopy, a sophisticated optical technique based on how light interacts with molecules.

At its core, Raman scattering works by shining light onto a material and analyzing how the light scatters back. The scattered light shifts in wavelength depending on the molecular vibrations of the material it interacts with. These shifts serve as chemical fingerprints, revealing what substances are present.

Stimulated Raman scattering takes this concept further. By using two synchronized laser beams, the method dramatically enhances signal strength, allowing for fast, high-resolution imaging. This makes it possible to observe chemical processes as they happen, rather than after the fact.

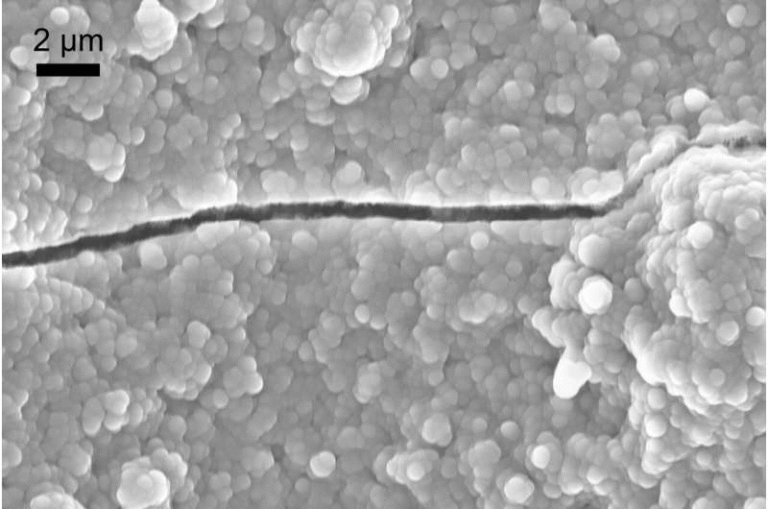

In this study, researchers applied SRS directly to operating reverse osmosis membranes, enabling real-time, in-situ observation of fouling. Crucially, the technique provides both three-dimensional structural data and chemical identification at the same time—a combination that current industrial tools cannot offer.

Watching Crystals Form in Real Time

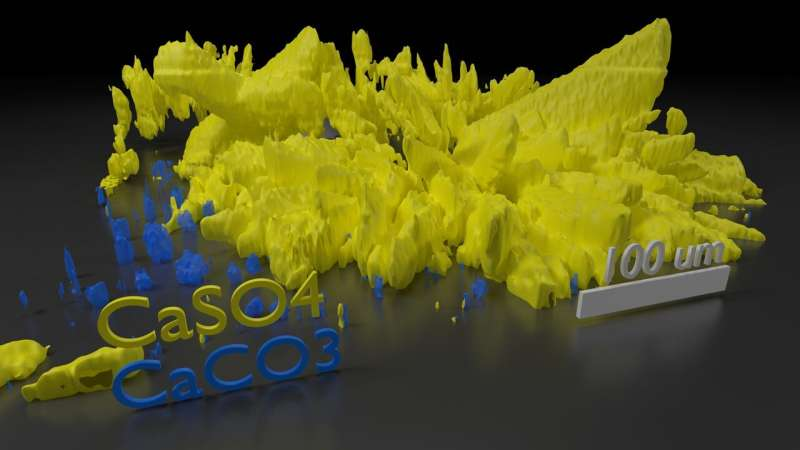

To test their system, the researchers focused on calcium sulfate and calcium bicarbonate, two ions commonly found in seawater and well known for causing mineral scaling in desalination systems.

Using SRS, the team was able to watch crystals form and grow on the membrane surface as the process unfolded. They observed multiple crystal morphologies and tracked how these structures evolved over time. The imaging revealed not just where fouling occurred, but exactly what the fouling material was made of.

This level of detail is especially important because different types of fouling require different mitigation strategies. Mineral scaling, organic fouling, and biofouling each respond differently to cleaning chemicals and operational changes. Being able to identify the chemical composition early allows operators to take targeted action instead of relying on trial and error.

Why Early Detection Is So Important

Fouling does not happen all at once. It begins at the molecular level, long before performance drops are noticeable in plant metrics. By the time traditional sensors detect a problem, membranes may already be significantly compromised.

The new SRS-based approach offers the possibility of early warning systems for membrane fouling. Operators could intervene sooner, adjust operating conditions, or schedule cleaning at optimal times. This could lead to lower energy use, reduced chemical consumption, and longer membrane lifespans.

Experts in membrane science emphasize that even modest reductions in fouling can have a major impact. Cleaner membranes mean higher water output, lower operating pressure, and reduced environmental footprint for desalination plants.

Beyond Minerals: Studying Complex Fouling Mixtures

While the initial experiments focused on calcium-based scaling, the researchers believe the technology has far broader potential. Real-world desalination systems often face complex mixtures of organic, inorganic, and biological materials, especially in coastal or brackish water environments.

Stimulated Raman scattering is well suited to studying these complex systems because of its chemical specificity. The team expects the technique could eventually help analyze biofilms, organic compounds, and mixed fouling layers that are difficult to characterize using conventional tools.

This opens the door to a deeper understanding of how fouling begins, how different materials interact on membrane surfaces, and which conditions accelerate or slow down the process.

The Bigger Picture: Making Desalination More Sustainable

Desalination is already a lifeline for many water-stressed regions, but it comes with trade-offs. The process is energy-intensive, and membrane maintenance represents a significant portion of operating costs.

Innovations like real-time membrane imaging could help address these challenges by improving efficiency, reliability, and sustainability. If plants can operate with fewer shutdowns, less chemical cleaning, and longer-lasting membranes, the overall environmental and economic costs of desalination could drop substantially.

As global demand for fresh water continues to grow, technologies that make desalination smarter and more efficient will play an increasingly important role in ensuring reliable access to clean water.

Research Reference

Lange Simmons, Y. et al. Stimulated Raman Scattering Microscopy: Real-Time In-Situ Physical and Chemical Characterization of Reverse Osmosis Desalination Membrane Scaling. Environmental Science & Technology (2025).

https://doi.org/10.1021/acs.est.5c10405