Fermented Fiber Innovation Aims To Reduce Fashion Waste And Ease Global Hunger

A new study from Penn State has introduced a surprisingly promising solution to two massive global challenges: fast-fashion pollution and world hunger. Researchers have developed a high-performance textile fiber made entirely from yeast biomass, the leftover material from brewing beer, producing wine, and manufacturing certain pharmaceuticals. This material is usually treated as waste, but the research team discovered that it can be turned into a strong, biodegradable, and cost-effective fiber that competes with traditional materials like wool and cotton.

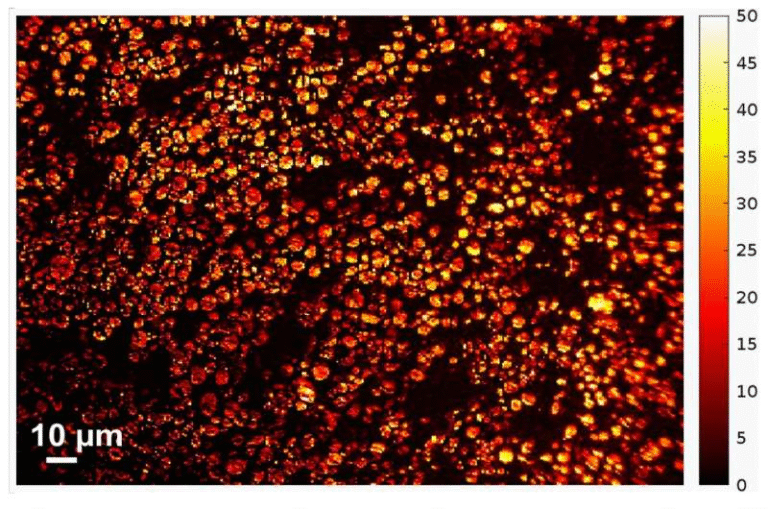

At the core of this innovation is yeast biomass composed of proteins, lipids, and sugars—a byproduct of fermentation industries. Instead of letting this byproduct accumulate or be discarded, the Penn State team repurposed it using a process they have spent more than a decade refining. They developed a method to pull aggregated proteins from the yeast, dissolve the resulting pulp using a solvent similar to the one used in producing Lyocell, and then push the mixture through a spinneret equipped with tiny nozzles that form continuous threads. These threads are then washed, dried, and spun into yarn. Because the solvent is recoverable at a rate of 99.6%, the process is designed to be highly sustainable and economically scalable.

One of the most impressive achievements highlighted in the study is that the team moved well beyond small-scale lab experiments. Working with an industrial collaborator in Germany, they managed to produce more than 1,000 pounds of fiber in a pilot-scale factory. The system ran in both continuous and batch modes for over 100 hours per production run, proving that the method is not limited to lab environments. The data collected during these large-scale trials fed into a detailed life-cycle analysis, examining the entire environmental footprint of the fiber—from raw materials to disposal. This included assessing cost, water use, greenhouse gas emissions, land use, and production output.

The findings showed that on a commercial scale, the fermentation-derived fiber could realistically compete with—and in several ways outperform—wool and other natural fibers. Production costs are projected to be $6 or less per kilogram, whereas wool often ranges from $10 to $12 per kilogram. Additionally, the process demands drastically fewer resources. Even after accounting for the land required to grow the crops that end up becoming yeast biomass, the new fiber uses far less land and water than cotton or wool. Cotton alone occupies around 88 million acres globally, with nearly 40% of that farmland located in India, a country that falls under the “serious” category on the Global Hunger Index. Producing just 2.2 pounds of raw cotton—the amount needed for a single T-shirt and a pair of jeans—can demand up to 2,642 gallons of water.

Because the fermentation-based fiber requires much fewer resources, researchers suggest it could free up land currently devoted to fiber crops, allowing it to be redirected toward food production. This could support efforts to reduce global hunger, a crisis that affected about 733 million people (roughly one in twelve) in 2024. The concept is simple: if fiber manufacturing shifts to a process that relies on fermentation waste rather than agricultural land, more space becomes available for growing food.

Another major benefit of this new fiber is its biodegradability. Unlike polyester—which makes up a huge portion of fast-fashion waste and persists for years in landfills—the new yeast-based fiber breaks down naturally after disposal. This makes it a promising alternative as over 66% of clothing produced annually in the United States ends up in landfills. The Penn State team’s goal is to offer a more sustainable, high-performance material without trading off environmental responsibility.

In their work, the researchers also referenced historical attempts to create fibers from proteins. Materials such as Lanital, produced from milk protein in the 1930s, and mid-20th-century fibers made from peanut and corn proteins showed early promise but were eventually dismissed due to weak performance or high production costs. Polyester, being cheap and strong, eventually became dominant. The challenge has always been balancing performance, cost, and sustainability, and earlier technologies struggled to achieve all three. According to the study, the new yeast-based fiber now meets that balance.

The team behind the research included Penn State collaborators and industry partners in Germany. A key contributor is Tandem Repeat Technologies, a company formed specifically to bring this type of biomimetic fiber to the market. The company’s chief technology officer and several researchers from the Thüringisches Institut für Textil- und Kunststoff-Forschung (TITK) in Germany helped scale the production. The technology has already been licensed to Tandem Repeat, and there is a patent pending.

A pilot-scale success is a major milestone, but the researchers emphasize that they are planning additional work to confirm viability at full industrial scale. They aim to test large-volume production, optimize costs even further, and explore how brands and manufacturers can adopt the fiber in real clothing lines. A related online brand, Sonachic, has been formed by Tandem Repeat to demonstrate the material’s commercial potential. The ultimate goal is to bring these fibers to the mass market.

Additional Background on Fermentation and Eco-Friendly Fibers

Since this fiber originates from fermentation waste, it’s useful to understand why fermentation is becoming such a popular source in sustainable materials research. Fermentation industries operate globally and continuously produce massive amounts of biomass waste from yeast and bacteria. Much of this material is rich in proteins, which can be extremely valuable if extracted and repurposed correctly. Using this biomass helps create a circular economy, where waste becomes input for new, high-value products.

Protein-based fibers also have unique characteristics. They can mimic the structure of naturally occurring protein assemblies such as amyloids, known for their durability. By designing fibers around such biological structures, scientists can create materials with excellent mechanical strength and elasticity. When coupled with sustainable solvent systems—like the one used in Lyocell production—these fibers avoid the harmful chemical residues associated with many synthetic fibers.

Understanding textile sustainability more broadly also helps make sense of why this advancement is exciting. The fashion industry is responsible for a significant share of global carbon emissions, microplastic pollution, and water usage. Cotton needs enormous quantities of land and water; synthetic fibers like polyester are made from petroleum and release microplastics into ecosystems. Biodegradable, low-impact protein fibers, especially those derived from waste streams, offer a promising alternative for reducing the industry’s footprint.

There is also increasing interest in biomanufactured materials across sectors. Companies are now exploring ways to turn mushrooms into leather alternatives, algae into dyes, and bacteria into building materials. The Penn State team’s work fits squarely into this trend, showing how biological systems can be harnessed to create sustainable and scalable materials.

Research Reference

Impact of biomanufacturing protein fibers on achieving sustainable development (PNAS, 2025)

https://doi.org/10.1073/pnas.2508931122