Generative AI Tool Helps 3D Print Personalized Items That Can Withstand Daily Use

Generative artificial intelligence has already reshaped how we create images, videos, music, and text, but its influence on the physical world has been far more limited. While AI can easily generate stunning digital visuals, turning those designs into real, usable objects has remained a major challenge. A new research project from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) aims to change that by introducing a generative AI system that can design customized 3D-printed objects that are both visually expressive and mechanically durable.

The system, called MechStyle, addresses one of the biggest barriers preventing AI-designed objects from entering everyday life: structural integrity. Until now, AI tools could easily personalize the look of a 3D model, but those aesthetic changes often weakened the object, making it prone to cracking, bending, or outright failure once printed and used.

Why AI-Designed Physical Objects Have Been So Rare

Despite the explosion of generative AI tools, you rarely see AI-designed phone cases, hooks, bowls, or accessories being used in homes or offices. The reason is surprisingly practical. Most generative AI systems do not understand physics.

When AI modifies a 3D model purely for style—adding ridges, bumps, textures, or dramatic shapes—it often alters load-bearing areas without realizing it. Previous studies conducted by the MIT researchers found that only about 26 percent of stylized 3D models remained structurally viable after AI-driven modifications. In other words, nearly three-quarters of those designs would break under normal use.

This disconnect between visual creativity and mechanical reality has been the missing link in AI-driven fabrication.

Introducing MechStyle and Its Core Idea

MechStyle was developed by Faraz Faruqi, a Ph.D. student in MIT’s Department of Electrical Engineering and Computer Science and a CSAIL researcher, in collaboration with researchers from Google, Stability AI, Northeastern University, and MIT’s Center for Bits and Atoms.

The core idea behind MechStyle is simple but powerful: combine generative AI with mechanical simulation. Instead of letting AI freely reshape a 3D object, MechStyle continuously checks whether those changes weaken the object’s structure and adjusts accordingly.

The result is a system that allows users to personalize objects while ensuring they can survive everyday wear and tear.

How MechStyle Works in Practice

Using MechStyle is designed to be approachable even for people who are not professional designers or engineers.

Users start by uploading an existing 3D model or selecting from preset assets such as vases, hooks, containers, or lampshades. They also specify the material they plan to use for printing, such as common plastics like polylactic acid (PLA).

Next, users provide a text prompt or image prompt describing the desired style. For example, someone might ask for a “cactus-like hook” or a vase with a rocky, stone-inspired texture.

At this stage, a generative AI model begins modifying the geometry of the object to match the requested style. However, unlike traditional AI stylization tools, MechStyle does not stop there.

The Role of Physics and Finite Element Analysis

As the AI changes the model, MechStyle runs finite element analysis (FEA), a type of physics simulation widely used in engineering. FEA breaks a 3D object into small elements and calculates how stress, weight, and force affect each region.

The system produces something like a stress heat map, highlighting which areas are strong and which are vulnerable. If the AI’s stylization begins to weaken a critical region—such as the base of a hook or the hinge of a pair of glasses—MechStyle intervenes.

To keep the system efficient, MechStyle uses an adaptive scheduling strategy. Instead of running expensive simulations after every tiny change, it tracks which parts of the model are being altered and only reruns physics simulations when those changes pose a structural risk.

This balance allows MechStyle to remain computationally practical while maintaining mechanical reliability.

From Fragile Designs to Near-Perfect Viability

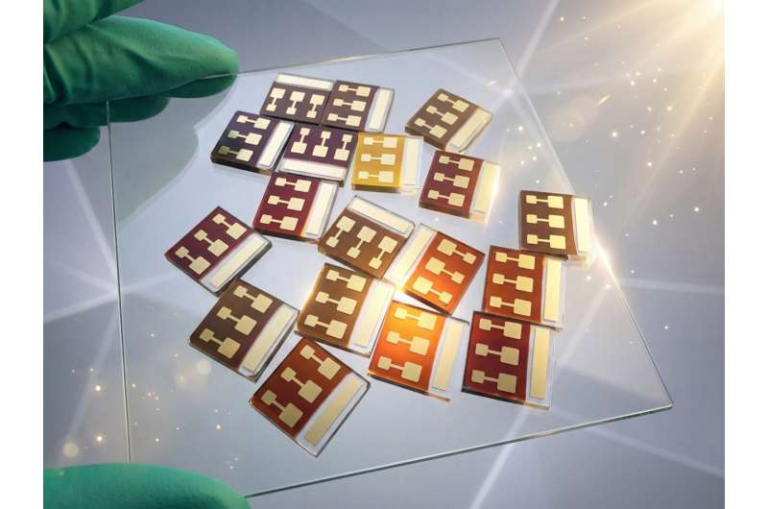

By integrating physics directly into the generative process, MechStyle dramatically improves outcomes. In tests involving 30 different 3D models with styles inspired by bricks, stones, cacti, and other complex textures, the system achieved up to 100 percent structural viability.

When stress thresholds were approached, MechStyle could either halt stylization entirely in risky areas or gradually reduce the intensity of modifications to keep the object safe. This dynamic adjustment proved far more effective than static design rules.

Two Modes for Creative Exploration

MechStyle includes two distinct modes to support both creativity and safety.

The freestyle mode allows users to quickly visualize different styles without structural checks. This is useful for brainstorming and exploring ideas.

Once users find a design they like, they can switch to MechStyle mode, where full mechanical analysis is applied. This second mode ensures the final model is suitable for 3D printing and real-world use.

Real-World Applications Beyond Decoration

The potential uses of MechStyle go far beyond decorative objects. The system has already been used to design functional accessories, such as wall hooks capable of holding bags, coats, and mugs, as well as pillboxes, lampshades, and containers with complex textures.

More importantly, MechStyle opens new possibilities for assistive technologies. The researchers demonstrated designs such as finger splints for dexterity injuries and utensil grips for users with motor impairments, all customized to individual needs while remaining structurally sound.

The system could also be valuable for rapid prototyping, allowing small businesses, designers, and makers to create and test personalized products for shops, hardware stores, or craft boutiques without extensive manual redesign.

Current Limitations and Future Directions

While MechStyle represents a major step forward, it still has limitations. The system cannot yet fix models that are structurally unsound to begin with. If a user uploads a flawed design, MechStyle will currently reject it rather than attempt repairs.

The researchers plan to address this in future versions, with the goal of allowing the system to reinforce and repair weak designs automatically.

Another major direction is enabling AI to generate 3D models entirely from scratch, rather than relying on presets or uploaded files. This would make MechStyle even more accessible to users who lack experience with 3D modeling or cannot find suitable designs online.

Why This Research Matters for Generative AI

Most successful generative AI systems today operate in two dimensions, where mistakes are cheap and consequences are minimal. In 3D, errors can mean wasted materials, broken objects, and unsafe products.

MechStyle demonstrates that embedding physical reality into AI systems is not only possible but essential for bringing generative AI into manufacturing, product design, and everyday life. It shows how creativity and engineering constraints do not have to be opposing forces.

As generative AI continues to move beyond screens and into the physical world, systems like MechStyle may define how personalized, functional objects are designed in the future.

Research paper:

https://dl.acm.org/doi/10.1145/3745778.3766655