How a New Acoustic Chip Uses Sound Waves Like Tiny Hands to Move and Control Objects

Sound is something we usually think of as background—music playing through speakers, voices traveling through the air, or traffic noise outside a window. But researchers at Virginia Tech are pushing sound far beyond its everyday role. A new electronic chip developed by a team led by Assistant Professor Zhenhua Tian shows how acoustic waves can be engineered to act like invisible hands, capable of grabbing, guiding, and moving tiny objects with remarkable precision.

This research, published in Nature Communications, represents a major step forward in how sound waves can be controlled on a chip. The technology has promising implications for medical diagnostics, noninvasive treatments, microfluidics, and even semiconductor cooling.

At its core, the work demonstrates how sound can be transformed from a passive carrier of information into an active mechanical tool.

Turning Sound into a Tool for Physical Manipulation

Acoustic waves are mechanical vibrations that move through solids, liquids, or gases. In everyday life, they carry energy to our ears, where we perceive them as sound. Under the right conditions, however, these waves can also exert physical forces on objects they encounter.

This phenomenon is already familiar in simple forms—like seeing grains of sand jump on a vibrating surface. Tian’s team is exploring how to harness this same principle at much smaller scales, where sound waves can manipulate cells, tiny particles, and fluid flows on electronic chips.

Such capabilities are especially valuable in biomedical settings. For example, acoustic waves could potentially separate particles in blood samples, guide cells without touching them, or assist in noninvasive surgical techniques where traditional tools would be too intrusive.

Why Traditional Acoustic Chips Fall Short

Most existing acoustic chips rely on a device called an interdigital transducer (IDT). An IDT converts electrical signals into surface acoustic waves that travel across a chip. While effective for generating sound, IDTs have a significant limitation: they typically produce flat, planar waves.

These flat waves are fine for simple vibration or transport, but they lack the flexibility needed for more advanced tasks. Trying to manipulate objects with them is a bit like pushing something around with the flat of your hand—you can move it in one direction, but you cannot lift, trap, or guide it freely.

For complex operations like trapping particles, steering them along precise paths, or creating controlled fluid motion, researchers need curved, overlapping, and highly customizable wave patterns. Standard IDTs simply cannot generate these kinds of waveforms.

Building a New Kind of Acoustic Wave Generator

To overcome this limitation, Tian’s team decided not to modify existing tools, but to create an entirely new wave-producing technology from scratch.

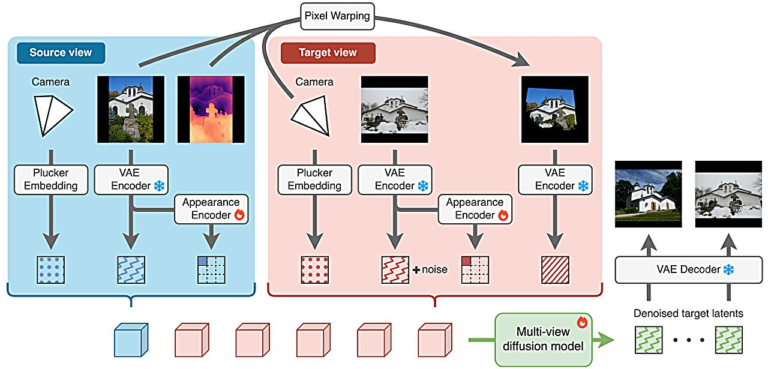

They reimagined both the shape of the acoustic transmitter and the electrode structures that generate the sound waves. The result is a chip-based system that can encode a highly customizable phase distribution, allowing precise control over how acoustic waves form and interact.

With this approach, the chip can tilt, curve, and synchronize waves in ways that were previously impossible. Instead of a single flat wave, the device can produce crisscrossing and harmonized acoustic patterns that work together to trap objects, guide energy, and transport fluids.

The team developed multiple versions of the chip, each capable of operating at different scales, power levels, and energy profiles. This flexibility means the same underlying technology can be adapted for a wide range of applications.

Longer Reach and Greater Power on a Single Chip

One of the standout achievements of the new design is its ability to generate long acoustic jets with more range and strength than traditional IDTs. All of this functionality is contained on a single electronic chip, making the system compact and highly integrable with existing technologies.

With only minor adjustments, the chip can switch between different wave behaviors, acting as an all-in-one instrument for acoustic manipulation. This level of versatility is crucial for real-world use, where conditions and requirements can vary widely depending on the task.

The Role of Metamaterials in Acoustic Control

Beyond being a new tool, the chip represents a new type of acoustic metamaterial. Metamaterials are engineered structures designed to control waves—whether sound, light, or heat—in ways that natural materials cannot.

In this case, the researchers carefully designed the chip’s material properties and geometry so it could reshape acoustic energy and redirect it toward specific functions. By controlling how energy flows through the system, the chip can perform tasks such as wave routing, particle manipulation, and fluid control with exceptional precision.

This adaptability is one of the technology’s most important strengths. Rather than being limited to a single function, the chip can be tuned for different purposes depending on the application.

Potential Medical and Biomedical Applications

The medical field stands to benefit significantly from this technology. Acoustic wave chips could assist in noninvasive procedures, where manipulating tissues or particles without direct contact is essential.

For instance, the chip could function like a miniature centrifuge, separating particles in blood samples without spinning machinery. It could also guide cells in lab-on-a-chip systems, improving diagnostics and research tools while reducing the risk of contamination or damage.

Because sound waves can travel through liquids and soft tissues, acoustic manipulation offers a gentler alternative to mechanical or electrical methods commonly used at small scales.

Beyond Medicine: Engineering and Industry Uses

The applications extend well beyond healthcare. In microfabrication and nanotechnology, precise control over particles and fluids is essential. The ability to guide micro- and nano-objects using sound could open new pathways for assembling tiny components or managing complex fluid systems.

The chip may also play a role in semiconductor cooling, where managing heat at small scales is a growing challenge. Carefully directed acoustic waves could help move heat away from sensitive components more efficiently.

Controlling Waves in Liquids and Solids

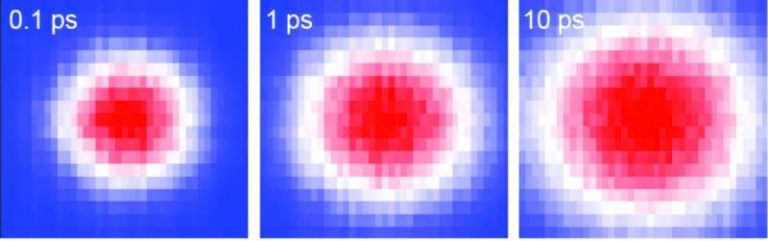

Early experiments show promising results when the chip is used to control acoustic waves in both liquid and solid environments. This dual capability broadens its potential uses and suggests the technology could be adapted for diverse operating conditions.

As the research continues, Tian’s team plans to explore new ways the chip can be applied, refining its performance and expanding its range of functions.

A Growing Field of Acoustic Manipulation

This work builds on the broader field of acoustic manipulation, sometimes referred to as acoustic tweezers. These techniques use sound pressure patterns to trap and move small objects without physical contact, making them especially useful in biological and microfluidic research.

What sets this new chip apart is the level of on-chip control and customization it offers, bringing complex acoustic manipulation closer to practical, scalable applications.

Research Reference

Nature Communications – “On-chip phased interdigital metamaterials enable versatile manipulation of surface acoustic waves, microfluids, and micro/nano-objects”

https://www.nature.com/articles/s41467-025-66488-z