Innovative Materials Push Stretchable OLED Displays Closer to Real-World Use

Organic light-emitting diodes, better known as OLEDs, are already at the heart of premium TVs, smartphones, laptops, and gaming displays. They offer vibrant colors, deep blacks, and excellent energy efficiency. But despite all their advantages, today’s OLED screens are still mostly rigid or only mildly flexible. Truly stretchable OLED displays—ones that can expand, compress, and conform to irregular or moving surfaces—have remained an unsolved challenge.

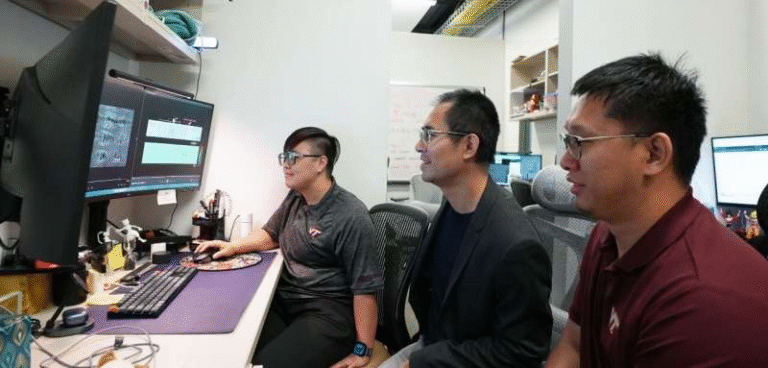

A new research breakthrough from the University of Chicago Pritzker School of Molecular Engineering (UChicago PME) may change that. Scientists have developed innovative materials that remove two of the biggest obstacles preventing fully stretchable OLED devices. Their findings, published in Nature Materials, bring stretchable displays significantly closer to matching the performance of conventional rigid OLED screens.

Why Stretchable OLEDs Matter

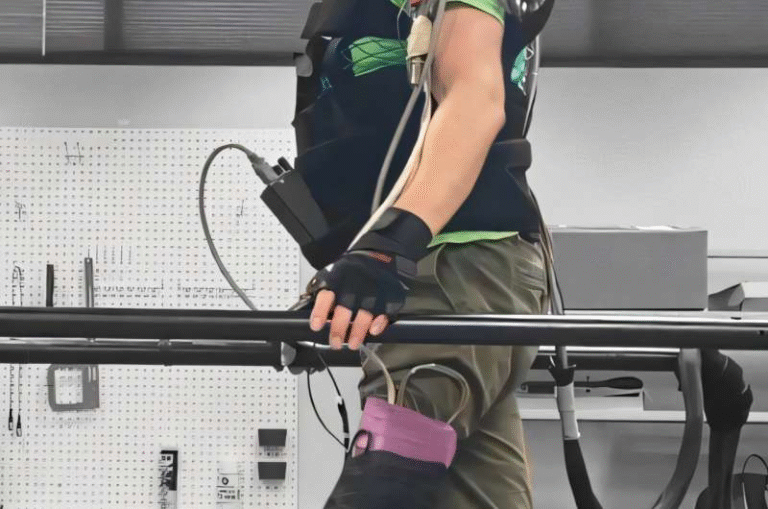

Stretchable OLEDs are not just about futuristic-looking screens. If displays could stretch and adapt to curved or soft surfaces, they could unlock a wide range of new technologies. These include wearable electronics that fit naturally on skin, medical implants that move with organs or tissue, and humanoid robots that interact more seamlessly with humans.

Beyond displays, stretchable OLEDs can also function as light sources for sensing and diagnostic devices. Applications could include monitoring blood glucose levels, detecting cancers, tracking heart conditions, and supporting other medical diagnostics that require close contact with the human body.

The key challenge has been making every part of an OLED device stretchable without sacrificing performance.

The Longstanding Problem with OLED Layers

An OLED is made up of multiple layers, each with a specific role. Over the years, researchers have successfully created stretchable light-emitting layers that can glow even when pulled to more than twice their original length. However, two critical layers stubbornly remained rigid:

- The cathode layer, which injects electrons into the device

- The electron transport layer (ETL), which helps electrons move efficiently toward the light-emitting layer

These layers are essential for brightness, efficiency, and overall device stability. Without stretchable versions of both, fully stretchable OLEDs were simply not possible.

The new study directly targets these two problem layers.

Turning Aluminum’s Biggest Weakness into a Strength

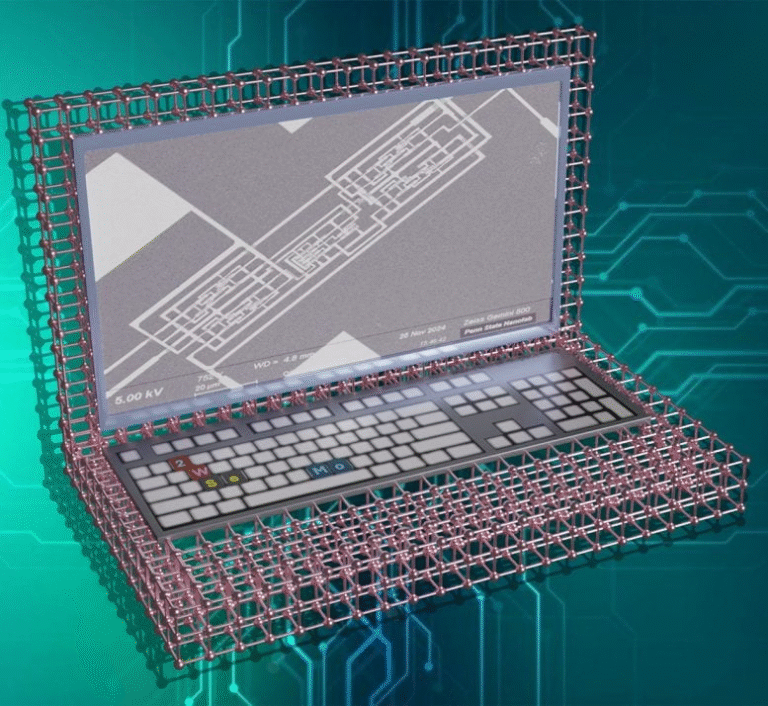

The cathode in most OLEDs is made of aluminum, a metal known for its excellent electrical properties. Unfortunately, aluminum is rigid and cracks easily when stretched. Replacing it with other materials usually leads to poor electron injection and reduced brightness.

The research team took a counterintuitive approach: instead of trying to prevent aluminum from breaking, they deliberately encouraged it—under controlled conditions.

They relied on a phenomenon known as liquid-metal embrittlement. Normally, this effect is considered dangerous because certain liquid metals can cause solid metals to crack and fail. Engineers are trained to avoid it at all costs.

In this case, the team embraced it.

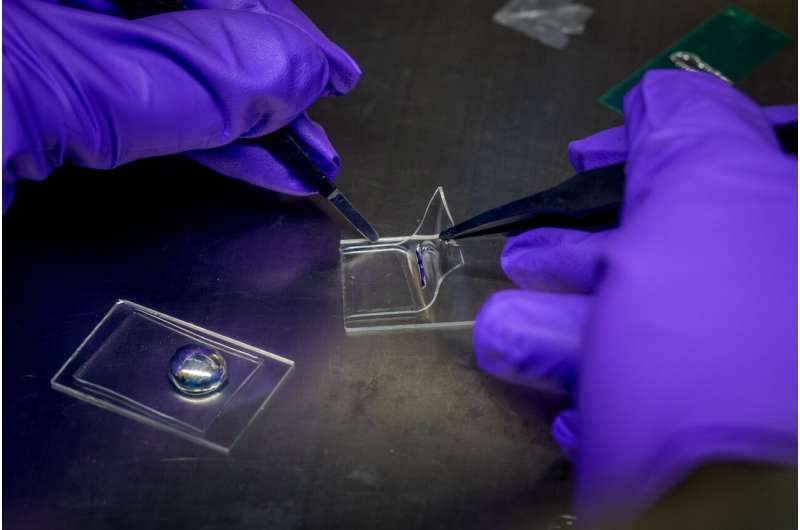

By embedding a thin aluminum film inside an elastic substrate and introducing a gallium-indium liquid metal alloy, they caused the aluminum to form tiny cracks rather than catastrophic fractures. These cracks open when the material is stretched and close again when it relaxes, behaving almost like folded paper.

The liquid metal flows into larger gaps, maintaining electrical continuity. The result is a stretchable aluminum cathode that continues to function even under repeated strain.

To improve bonding and stability, aluminum particles were pre-mixed into the gallium-indium alloy, giving the material a gel-like behavior rather than acting like a free-flowing liquid. Aging tests showed that its electrical properties remained unchanged for at least one month, indicating promising durability.

Designing a New Family of Stretchable Electron Transport Polymers

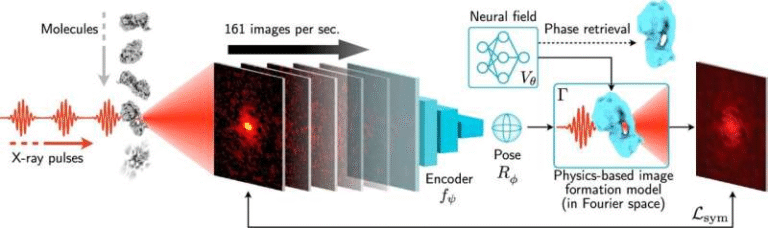

Solving the cathode problem was only half the battle. Electrons still need to travel efficiently from the cathode into the light-emitting layer, and that requires a high-quality electron transport layer.

Traditional ETLs are brittle and crack under strain. Making them flexible often comes at the cost of poor conductivity.

To address this, the researchers designed an entirely new family of conductive polymers. These polymers are built with electron-deficient triazine-based conjugated rings that provide conductivity, connected by alkyl chains that add stretchability.

This design allows precise tuning. Adding more alkyl chains increases stretchability but reduces conductivity. Reducing them improves conductivity but limits stretch. By adjusting this ratio, the team achieved a balanced ETL that supports both efficient electron transport and mechanical stretching.

When combined with the new stretchable aluminum cathode, this polymer ETL enables smooth electron injection even when the device is stretched significantly.

Performance That Rivals Rigid OLEDs

One of the most impressive aspects of this work is how closely the stretchable OLEDs match traditional rigid devices. The fully stretchable OLEDs demonstrated high brightness, low operating voltage, and strong efficiency, approaching the performance of standard OLEDs made on glass or plastic substrates.

The devices maintained stable light emission under large mechanical strain, including stretching to more than 100% of their original length. Repeated stretching cycles caused minimal degradation, showing that the materials can withstand real-world mechanical stress.

This closes a major performance gap that has limited stretchable OLEDs for years.

The Role of Energy Level Alignment

Efficient OLED operation depends on proper energy level alignment between layers. If energy barriers are too high, electrons get stuck, reducing brightness and efficiency.

The newly developed cathode and ETL work together to create a smooth energy landscape for electrons. This alignment is crucial for maintaining brightness while keeping power consumption low, especially in stretchable devices where mechanical deformation can disrupt electronic pathways.

How This Fits into the Bigger OLED Landscape

Flexible OLEDs already exist and are widely used in foldable phones and curved displays. However, flexible is not the same as stretchable. Flexible displays bend but do not significantly change size. Stretchable displays can expand, compress, and adapt dynamically.

Compared to earlier stretchable OLED attempts using silver nanowires, carbon nanotubes, or conductive polymers like PEDOT:PSS, the new aluminum-based cathode offers lower work function, better electron injection, and compatibility with high-performance OLED architectures.

This makes the approach particularly attractive for future commercial applications.

What Comes Next for Stretchable OLED Technology

The researchers aim to push this technology toward commercial viability, with long-term goals of integrating stretchable OLEDs into consumer electronics, healthcare devices, and soft robotic systems.

Key challenges ahead include large-scale manufacturing, long-term durability, and integration with existing production methods. Still, this work provides a clear materials blueprint for overcoming the toughest barriers.

By solving the cathode and electron transport layer problems together, the study marks a major step toward fully stretchable, high-performance OLED displays that behave more like human skin than rigid glass.

Research Paper:

https://www.nature.com/articles/s41563-025-02419-z