Interpretable Machine Learning Accelerates the Search for Sinter-Resistant Nanocatalyst Supports

A new study from the University of Michigan presents a detailed and highly efficient computational framework that speeds up the discovery of sinter-resistant support materials for metal nanoparticle catalysts. This research focuses particularly on platinum (Pt) nanoparticles, which are widely used in industrial chemical reactions but tend to sinter, or clump together, at high temperatures. Sintering reduces their surface area and drastically lowers catalytic performance. Because platinum is expensive, anything that hides the active metal atoms is a problem—and preventing sintering is crucial for maintaining efficiency in real-world catalytic processes.

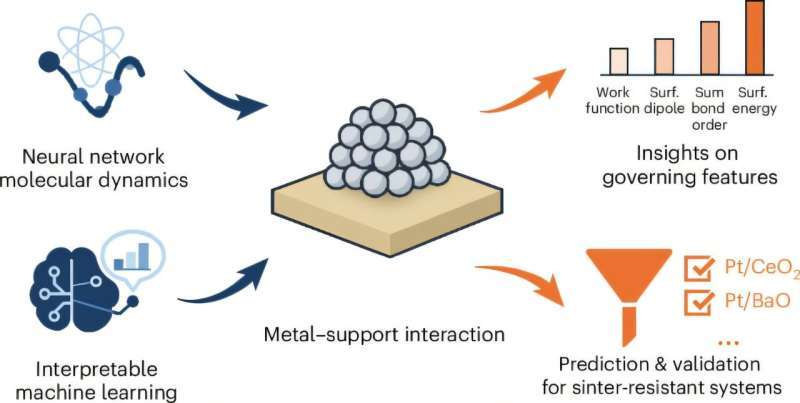

Traditional experimentation to identify the best support materials is slow, expensive, and far too limited in scale to explore the tens of thousands of possible metal-oxide combinations. Past computational efforts have relied on neural network molecular dynamics, a simulation technique that speeds up modeling how atoms move but still remains too computationally costly for very large searches. The University of Michigan team expanded on this idea by integrating interpretable machine learning into the workflow, creating a multistep system that balances accuracy with speed and, importantly, helps researchers understand why certain materials work better than others.

The research team demonstrated that this combined approach allows screening more than 10,000 candidate support materials, something impossible to achieve using conventional simulations alone. Their efforts ultimately led to the discovery of a promising sinter-resistant support: barium oxide (BaO).

Why Nanoparticle Sintering Is Such a Challenge

Metal nanoparticles act as catalysts because their surfaces are highly reactive. The smaller the particles, the more surface atoms are available to drive chemical reactions. However, as temperatures rise, these nanoparticles tend to migrate across the surface of their support material and fuse together. This sintering process is a key reason catalysts degrade over time.

Preventing sintering requires support materials that strongly anchor the nanoparticles, making them less likely to move and coalesce. But because so many physical and electronic factors influence nanoparticle–support interactions, identifying the right combination through experiments alone is nearly impossible. The new framework addresses this problem by predicting these interactions with far greater speed and scale.

How the Research Team Built Their Predictive Framework

The workflow developed by the researchers follows a progression from the most physically accurate but slowest methods to the fastest and simplest ones:

- Quantum chemical calculations

These highly accurate simulations model how atoms interact at the electronic level. They are extremely computationally expensive but provide the foundational data needed for training further models. - Neural network molecular dynamics (NN-MD)

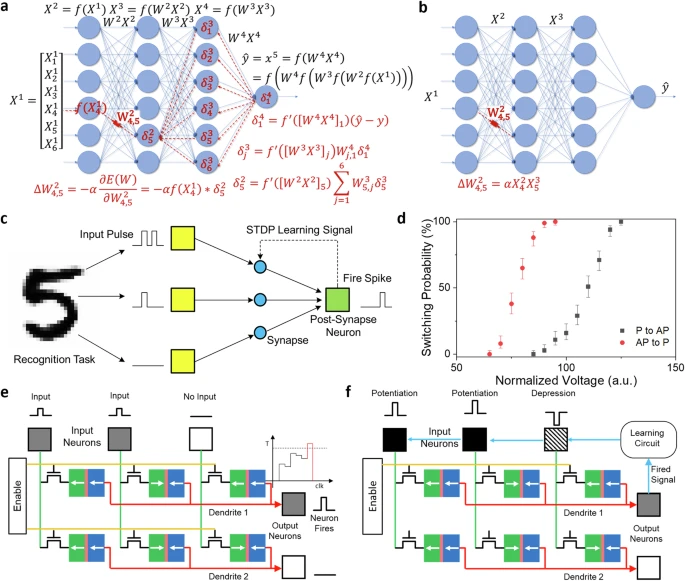

Using knowledge derived from the quantum calculations, NN-MD simulates atomic motion under high temperatures much more efficiently. Still, even this method is too slow to screen tens of thousands of materials. - Interpretable machine learning (iML)

This is where the breakthrough happens. The iML model is trained using the results of 203 detailed nanoparticle-support simulations. Instead of working as a black box, it evaluates 12 specific physical properties of support materials that are known to influence sintering and metal-support interactions.

Because the model is interpretable, researchers can actually see which features matter most. According to the findings, surface energy played the most influential role in determining sintering resistance. High surface energy means the support holds onto metal nanoparticles more tightly, reducing the chance of movement and aggregation. The model also revealed additional electronic and structural factors that contribute to stability, all validated through case studies involving quantum chemical calculations.

Screening 10,662 Candidate Materials

Once the iML model demonstrated accuracy and consistency, the team used it to evaluate 10,662 different metal-oxide materials. This enormous search, which would take months or years with traditional methods, became manageable due to the model’s computational efficiency. The interpretable ML step thinned the list down to 148 promising candidates, which then underwent more detailed examinations.

Through this follow-up testing, the researchers identified BaO (barium oxide) as a highly effective support for platinum nanoparticles under high temperatures. This means BaO can keep Pt particles from sintering, thus maintaining catalytic activity for longer periods. Since platinum catalysts are essential for many chemical and energy-related processes, improvements in stability directly translate to industrial benefit.

Why Interpretable Machine Learning Matters Here

Interpretable models are especially valuable in materials science because they help researchers understand why certain materials perform the way they do. This avoids blind trial-and-error and supports knowledge-driven discovery. In this study, the model’s transparency helped confirm the importance of features such as surface energy, electronic descriptors, and structural attributes. These insights can now guide future catalyst design strategies and reduce reliance on expensive simulations.

The researchers also point out that this hierarchical combination of modeling approaches is similar to medical diagnostics: you start with the most accurate (like a throat culture), then use quicker, less precise tools (such as a thermometer) to screen large populations efficiently. Each step is designed to filter candidates before committing more resources.

Broader Applications Beyond This Case Study

Although this research focused on platinum nanoparticles, the framework itself is broadly applicable. Any catalytic system where nanoparticle sintering is a concern can benefit from this approach. Chemical plants, energy conversion technologies, environmental catalysis, and emerging green-chemistry applications all rely heavily on catalysts that must withstand high temperatures and long operating times.

If engineers or researchers already have access to certain oxides or support materials, they can use the simplest version of the model to assess whether those materials might be effective. If the results look promising, they can move up the hierarchy to more detailed simulations. This scalable approach allows organizations with different resource levels to participate in catalyst discovery.

Additional Insight: Why Machine Learning Has Become Essential in Catalyst Research

Catalyst discovery traditionally involves slow cycles of experimentation and incremental testing. Machine learning changes this dynamic by enabling rapid predictions across enormous design spaces. More importantly, hybrid approaches like the one in this study maintain a balance between physical accuracy and computational efficiency.

In materials science, ML models often must be trained on high-fidelity data that is expensive to generate. The University of Michigan team’s approach is clever because it uses a small number of expensive simulations to teach neural networks and interpretable models how to generalize. The result is a system that can explore thousands of hypothetical materials and give meaningful predictions without needing to simulate each one from scratch.

As more high-quality materials data becomes available, and as interpretability techniques continue to improve, these frameworks will only become more powerful. We may see similar approaches used to design batteries, semiconductors, membranes, and other advanced materials.

Research Paper

Predictive model for the discovery of sinter-resistant supports for metallic nanoparticle catalysts by interpretable machine learning

https://www.nature.com/articles/s41929-025-01417-3