Iron-On Electronic Patches Could Make Wearable Tech as Easy as Ironing a Shirt

Iron-on patches have long been a simple solution for fixing torn clothes or adding decorative flair to jackets, backpacks, and hats. Now, researchers have taken that familiar idea and turned it into something far more futuristic. A new study shows that iron-on electronic patches can be used to attach working electrical circuits directly onto fabric, opening the door to a new generation of wearable electronics that are easier, softer, and more practical than ever before.

The research comes from a team at Virginia Tech, led by materials scientist Michael D. Bartlett, and was published in the journal ACS Applied Materials & Interfaces in 2025. Their work focuses on solving one of the biggest challenges in wearable technology: how to integrate electronics into clothing without making it uncomfortable, fragile, or difficult to manufacture.

Why Integrating Electronics into Fabric Is So Hard

Fabrics are naturally soft, flexible, stretchable, and breathable, while most electronic circuits are rigid and delicate. This mismatch has slowed down the adoption of smart clothing, even though the potential applications are huge. Wearable electronics could support health monitoring, environmental sensing, robotics, and human–machine interfaces, but only if they can survive real-world use.

Previous approaches have had serious drawbacks. Some researchers have used conductive inks printed directly onto fabric, but these circuits tend to degrade when exposed to moisture, repeated bending, or washing. Other designs embed liquid metal circuits between layers of protective polymers, which improves durability but often sacrifices stretchability and comfort.

The Virginia Tech team decided to try a different route—one that borrows from something people already know how to use at home: a hot iron.

The Core Idea Behind the Iron-On Electronic Patch

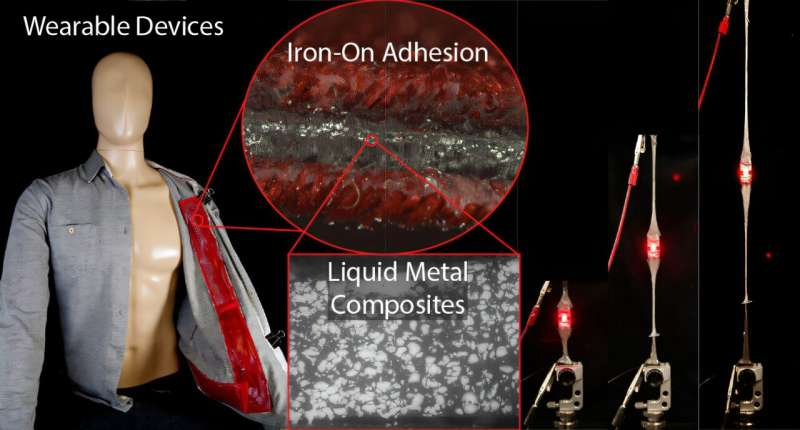

The researchers created a stretchable, electrically conductive film that can be bonded to fabric using heat. The key innovation lies in the material itself. They combined microscopic droplets of a gallium-indium liquid metal alloy with a polyurethane-based adhesive to form a soft composite.

Here’s how the process works:

- Liquid metal droplets are mixed into a thermoplastic polyurethane (TPU) solution.

- The mixture is poured into a thin layer and left to air-dry for about 24 hours.

- Once dry, it forms a soft, elastic, conductive sheet.

- Small pieces of this sheet are cut and placed onto fabric.

- Applying heat with a standard iron activates the adhesive, causing the patch to bond strongly with the fabric fibers.

After cooling, the patch stays firmly attached while remaining flexible and stretchable.

Tested on Real Fabrics, Not Just Lab Samples

One of the strengths of this research is that it wasn’t limited to idealized materials. The team tested their iron-on patches on a variety of commonly used textiles, including:

- Plain-weave polyester

- Cotton twill

- Knit spandex

- Mesh jersey fabric

In each case, the polymer in the patch formed a strong bond with the fibers, holding the layers together even under mechanical stress. This matters because wearable electronics need to function on many different types of clothing, not just specialty fabrics.

Demonstration One: A Flexible LED Circuit

To show that the technology actually works in practice, the researchers built several proof-of-concept devices. In one demonstration, they ironed a circuit shaped like their university’s logo onto a piece of fabric and connected it to five LEDs.

The result was impressive. The LEDs stayed lit even when the fabric was:

- Folded repeatedly

- Twisted in different directions

- Stretched significantly

This showed that the conductive pathways remained intact despite constant deformation—exactly the kind of stress clothing experiences during everyday wear.

Demonstration Two: A Microphone Hidden Inside a Shirt

The second demonstration focused on a more complex and realistic application. The team integrated a stretchable wire microphone into a button-up shirt, using iron-on circuits to deliver power and transmit audio signals underneath the fabric.

The iron-on circuitry routed the signal to an external recording device, all while staying hidden and unobtrusive. Performance tests showed that the microphone could record sound across the entire human hearing range, with audio quality comparable to traditional microphone setups. Importantly, the iron-on system added less bulk, making it far more suitable for wearable use.

Not Just for Rigid Components Like LEDs

While LEDs and microphones are useful demonstrations, the researchers emphasize that this technology goes much further. The conductive patches are compatible with soft circuits, meaning they could be used in applications where flexibility is essential.

Potential uses include:

- Soft robotics, where electronics must move with deformable structures

- Health-monitoring garments, such as shirts that track breathing or muscle activity

- Environmental sensing clothing, capable of detecting temperature, humidity, or pollutants

- Human–machine interfaces, where clothing itself becomes an interactive surface

Because the patches are iron-on, they could be applied quickly and repaired easily, making them appealing for both industrial manufacturing and consumer-level customization.

What Makes Liquid Metal Special

Liquid metals like gallium-indium alloys are unusual because they conduct electricity like traditional metals but remain fluid at or near room temperature. When embedded as microscopic droplets inside an elastic polymer, they create conductive pathways that can stretch and bend without breaking.

This combination allows the patch to maintain electrical performance even under extreme deformation. Unlike solid metal wires, which can fracture when stretched, liquid metal simply changes shape along with the surrounding material.

Why Heat-Activated Adhesion Matters

The use of a heat-activated adhesive is another crucial part of the design. Iron-on bonding allows the electronic patch to integrate directly with fabric fibers, rather than sitting loosely on top. This improves durability and ensures consistent electrical contact.

It also means the process is fast and accessible. There’s no need for specialized equipment, complex sewing techniques, or chemical treatments. In principle, anyone with an iron could apply these patches.

The Bigger Picture for Wearable Electronics

This research represents a meaningful step toward practical, everyday wearable electronics. By combining familiar tools with advanced materials, the team has lowered one of the biggest barriers to adoption: ease of integration.

Instead of designing clothes around electronics, electronics can now be added to clothes after they’re made, or even retrofitted onto existing garments. That flexibility could significantly accelerate innovation in smart textiles.

Research Reference

Iron-On Wearable Electronics through Liquid Metal Adhesive Composites

ACS Applied Materials & Interfaces (2025)

https://doi.org/10.1021/acsami.5c13752