New Knitting Machine Prototype Creates Solid 3D Objects With Unusual Flexibility

A new research project from Cornell University and Carnegie Mellon University has introduced a prototype knitting machine that can build solid 3D structures instead of the usual flat, flexible sheets that traditional knitting produces. This machine stands out because it can add stitches in any direction—forward, backward, and even diagonally—allowing it to craft shapes that were previously impossible using knitting techniques. The result is a system that behaves much more like a 3D printer made of yarn, giving designers, engineers, and researchers a fresh tool for creating complex, customizable textile-based objects.

How the Machine Works

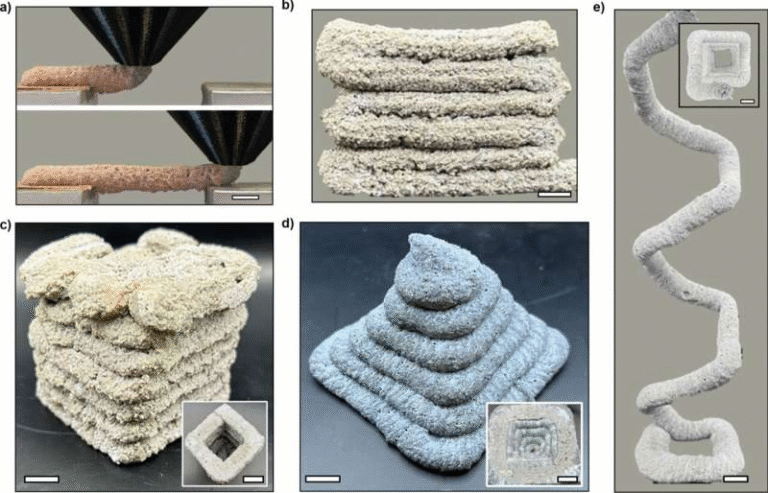

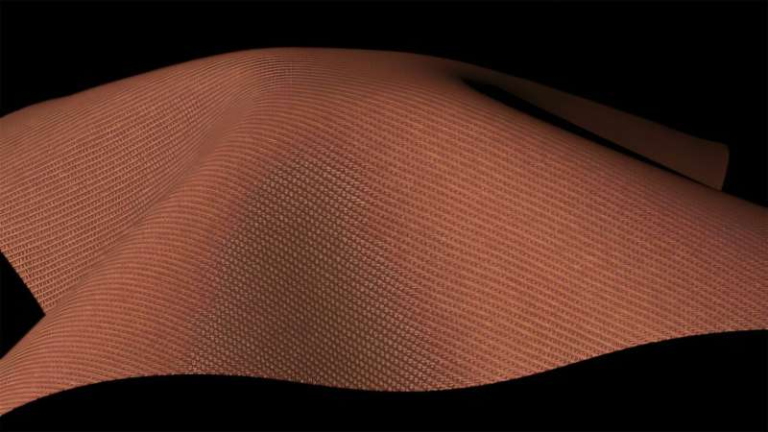

The prototype uses a 6×6 array of knitting needles, totaling 36 needles arranged in a square grid. Each needle is built from a 3D-printed symmetrical double hook attached to a brass support tube. The front and back portions of these hooks move independently, which allows the machine to choose whether to perform a knit or a purl stitch by controlling which part of the hook collects the yarn loop first. This mechanical setup gives the system an unusual level of control over stitch direction and connectivity.

Above this needle array is a knitting head that dispenses yarn. What makes this machine particularly flexible is that the yarn head can move freely to any individual needle on the grid. Instead of following the fixed left-to-right path of traditional knitting machines, this system can deposit stitches at arbitrary positions. Because of this freedom, it becomes possible to knit layers horizontally while gradually pushing the finished structure downward through the bed of needles. As more layers are added, the fabric builds upward into a true 3D object, rather than a flat sheet that must later be shaped or assembled.

To control all this motion and stitch placement, the researchers created a custom software library. This library includes instructions for different stitch types and can generate the full knitting program needed for any given shape. The software helps translate a desired structure into the specific, step-by-step actions the machine must take to reproduce it.

What the Machine Can Make So Far

Although still a prototype, the machine has already demonstrated an impressive range of shapes. The research team has successfully produced objects like a C-shaped block and an inverted quarter pyramid, proving that the system can handle overhangs, corners, and directional changes that would challenge earlier knitting machines.

Unlike previous attempts at so-called solid knitting, which were restricted to very limited forms, this machine provides a level of geometric freedom similar to the flexibility you’d expect from a 3D printer—just using yarn instead of plastic. This architectural freedom also opens the door to creating regions of varied thickness, density, and stiffness within a single object, something particularly useful for engineering applications.

Current Limitations

As promising as the machine is, it’s still in an early stage. The prototype is relatively slow and sometimes unreliable. It can drop loops, catch the yarn on the wrong needle, or fail to maintain consistent tension. These issues are expected in early fabrication systems, and the researchers already have plans to make the design more robust and scalable.

Right now, the 6×6 needle bed limits object size, but the team notes that scaling should be as simple as adding more needles and expanding the frame. Larger machines could potentially handle far more detailed structures.

Why This Matters

Solid knitting is a young but exciting fabrication method. Textiles are naturally flexible, lightweight, and mechanically interesting. Being able to construct volumetric textile objects directly—without cutting, folding, stitching, or assembling—could lead to breakthroughs in several industries.

Knitted structures have unique mechanical behaviors because of the way loops interconnect. They can compress, stretch, and absorb force in ways that solid printed plastics cannot. This makes knitted volumes ideal for areas where softness, flexibility, or impact absorption are important.

Potential Applications

With more development, this technology could have applications in:

Medical Engineering

The ability to knit 3D forms with variable stiffness and gradient thickness could be useful for creating scaffolds for artificial ligaments, veins, or other tissue structures. Because knitting naturally creates interconnected loops, the resulting structures have built-in pathways that can encourage biological growth or fluid flow.

Soft Robotics

Soft robots use flexible materials to move in organic, natural ways. A 3D-knitted structure could provide built-in elasticity and mechanical complexity without needing bulky external components.

Wearables and Textiles

Customized padding, ergonomic shapes, or breathable yet structured components could be produced as single, seamless pieces. Imagine shoes, helmets, or furniture cushions manufactured directly from yarn into their final form.

Sustainable Manufacturing

Because the objects are made of yarn, the environmental impact could be lower than that of plastics used in 3D printing. Some yarns are biodegradable or recyclable, making this an appealing fabrication method for eco-conscious design.

Additional Background: Understanding the Basics of Knitting Technology

To appreciate why this new machine is such a leap forward, it helps to understand the basics of knitting itself.

Traditional knitting machines produce flat fabrics by passing loops of yarn through other loops. They do this in straight lines—either across a row or around a cylinder. Even computerized machines follow strict path constraints. This means that if you want a 3D shape, you usually have to cut and sew multiple pieces together or rely on stretchability to approximate a 3D form.

In contrast, this new machine builds shapes directly. Because stitches can originate anywhere on the needle grid, the machine effectively draws with yarn in two dimensions while building upward in the third.

Another challenge in knitting complex structures is loop stability. Loops want to unravel if not held in place properly, which is why controlling stitch order, tension, and direction is critical. The double-hook needle design in this prototype improves reliability by letting the system choose which direction a stitch forms.

Why Stitch Direction Matters

Normal knitting relies on two basic stitches: knit and purl. They are mirror images of each other. Alternating between them creates patterns, textures, and structural variations. A machine that can choose either stitch at any position on a grid gains an enormous amount of design freedom. This is part of what makes the research team’s approach so versatile.

The Human Effort Behind the Machine

One charming detail from the research is that the lead researcher built the prototype mostly from scratch in his basement during the COVID-19 pandemic. Many of its components are 3D-printed, showing how modern fabrication tools can accelerate experimentation even for complex mechanical systems. The collaboration between Cornell and Carnegie Mellon also highlights how cross-institution creativity drives innovation in computational textiles.

What’s Next for Solid Knitting

Future work will likely focus on:

- enlarging the needle array

- improving mechanical reliability

- developing better software for shape design

- testing diverse yarn types or materials

- exploring industrial-scale fabrication

As the system matures, we may see entire new categories of textile-based products emerge.

Research Reference:

Using an Array of Needles to Create Solid Knitted Shapes – https://doi.org/10.1145/3746059.3747759