Recyclable Liquid-Metal Composite Paves the Way for Flexible and Reconfigurable Electronics

A team of researchers at the University of Washington has developed a recyclable, flexible, and reconfigurable electronic material that could reshape how future gadgets are built, used, repaired, and eventually recycled. The work focuses on reducing global electronic waste, which is rapidly increasing and is expected to reach 60 million tons per year by 2030 if no substantial changes are made to the way electronics are manufactured and disposed of. The researchers’ new approach looks at the problem from the beginning rather than the end, proposing a material that can be repeatedly reused, reshaped, and broken down for raw-material recovery.

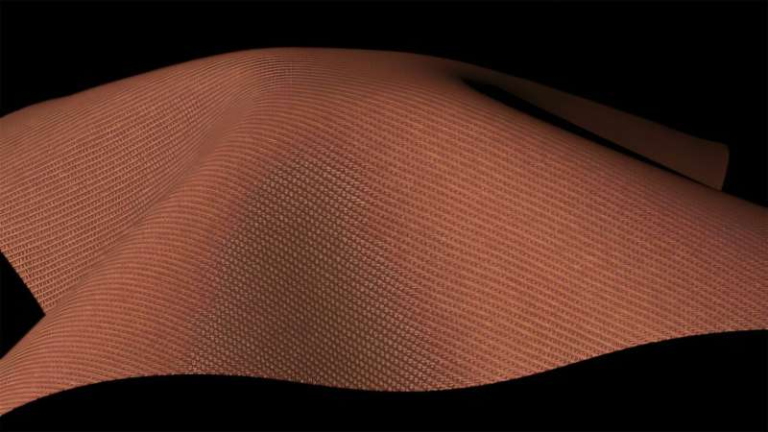

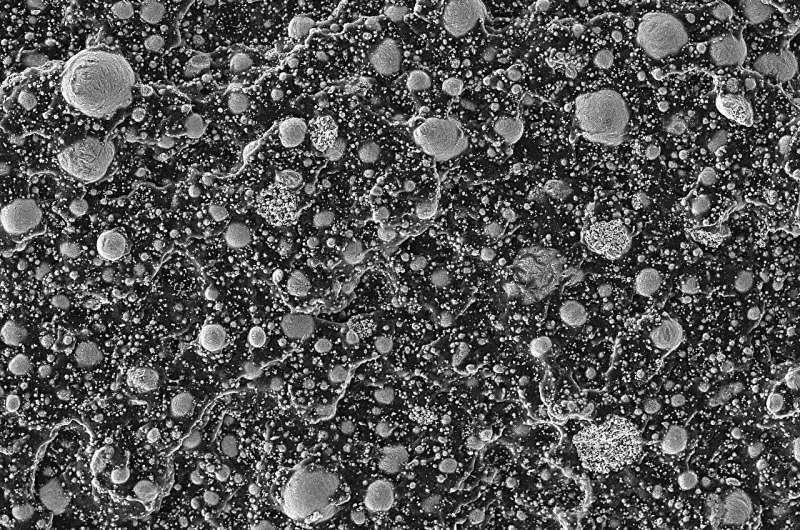

This new composite is made from a stretchy vitrimer-based polymer infused with microscopic droplets of a gallium-based liquid metal alloy. Together, these components create a material that is soft, durable, conductive, and easy to reconfigure. What makes it stand out is that users can form electrical circuits on it without adding extra wires or components—simply by lightly scoring patterns on the material’s surface that connect the embedded metal droplets. These droplets touch after scoring, allowing electricity to flow through the patterned region while the rest of the material remains electrically insulating.

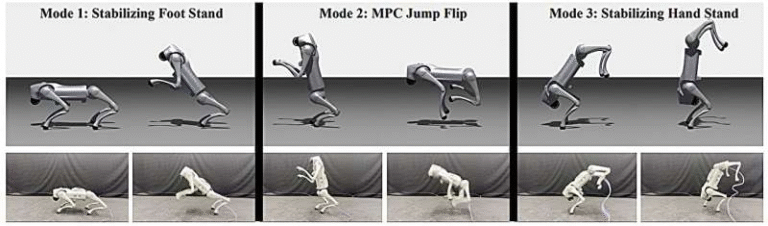

Another important feature is its self-healing capability. The material can be cut into multiple pieces, rearranged into new shapes, and then bonded together again using only heat and pressure. Circuits drawn on the material continue functioning even after being chopped apart and reconnected in a different configuration. This makes the composite appealing for future electronics that need to be reshaped, repaired, or adapted on the fly, which is especially promising for wearables, soft robotics, and flexible sensing systems.

Beyond reconfiguration, one of the most significant accomplishments is that the composite is fully recyclable. The polymer network can be chemically broken down, freeing the embedded liquid metal droplets for reuse. In experiments, the team successfully recovered 94% of the liquid metal from their samples. Because gallium-based alloys are relatively expensive, this recovery rate is essential for the material’s long-term sustainability and cost-effectiveness.

The polymer itself is based on vitrimer chemistry, which allows for dynamic bond exchange under heat. This is what gives the material its ability to be reshaped and repaired. Vitrimers behave like traditional thermosets under normal conditions—strong and stable—but gain malleability when heated. When combined with liquid metal microdroplets, the result is a composite that is both mechanically strong and highly conductive after surface scoring.

The researchers’ approach differs substantially from conventional circuit boards, which are typically made by laminating copper traces onto rigid boards composed of fiberglass and resin. These boards are extremely difficult to recycle because of how tightly bonded their components are. Separating metals from other materials requires energy-intensive or hazardous processes. The newly developed composite, in contrast, is designed so the valuable components can be separated easily, shifting the design philosophy toward reuse and recoverability.

The team behind the work has been exploring liquid-metal-infused polymers since 2019, using machine learning to optimize different formulations. Their focus shifted strongly toward recyclability as the cost of liquid metal alloys rose over time. This motivated them to create a material that is not only functional but also sustainable.

How the Liquid Metal Contributes to Conductivity

The composite uses a gallium-based alloy that remains liquid at room temperature. Each tiny droplet is suspended inside the polymer. The droplets only form conductive pathways when the surface is scored or patterned, which breaks the thin oxide shells around them and pushes them into contact with each other. This technique makes forming circuits extremely simple—no fragile wires, no soldering, and no need for rigid circuit board structures.

Because the droplets are embedded throughout the material, conductivity is possible in any region that is intentionally patterned. The rest stays insulating, allowing precise control of the electronic layout.

The Recycling Process

A major advantage of the new material is the ease of recovering the embedded liquid metal. The recyclable polymer can be dissolved using a mild chemical process that breaks down the vitrimer network. Once dissolved, the liquid metal droplets are freed and can be collected, purified, and reused in new composite batches.

Recovering 94% of the metal in research trials shows that the approach is feasible for circular-economy electronics. The polymer itself is also reprocessable because vitrimer chemistry allows it to be reshaped and reformed under heat.

Why This Matters for the Future of Electronics

The researchers hope this material can inspire a new era of devices that are built to be reused rather than thrown away. Instead of manufacturing millions of disposable gadgets, manufacturers might develop electronics that can be repaired, reconfigured, or fully recycled. This is especially important as the world’s appetite for electronics grows, and with it, the environmental cost of producing and discarding them.

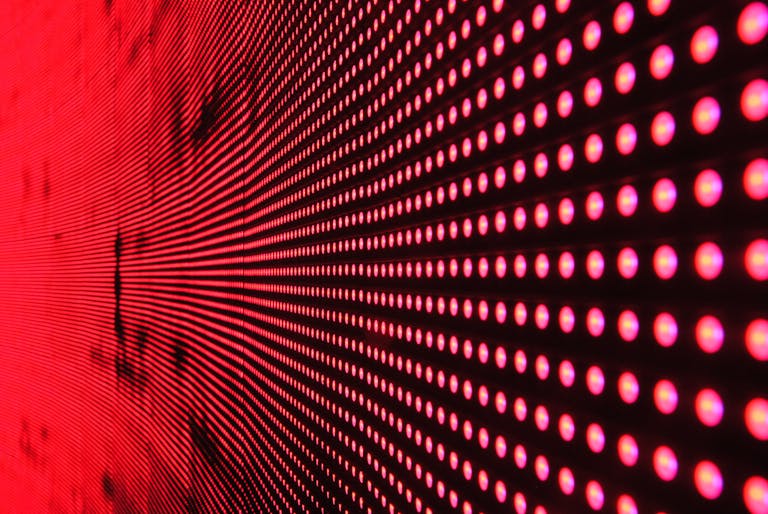

Soft robotics, stretchable batteries, wearable health sensors, and flexible displays are all areas that could benefit from this composite. The material’s durability, flexibility, conductivity, and recyclability make it a good fit for next-generation technological designs.

Broader Context: Why Electronic Waste Is a Global Challenge

Electronic waste, or e-waste, is one of the fastest-growing categories of waste in the world. It contains valuable materials such as gold, copper, and rare elements, but recovering them is difficult because traditional electronics are glued, laminated, or soldered together. When not disposed of properly, e-waste can release lead, mercury, and other harmful substances into the environment.

Many modern devices—phones, laptops, wearables—are designed for compactness and performance but not for disassembly or recycling. As a result, only a small fraction of global e-waste is properly recycled. By contrast, the newly developed composite is built around the idea of easy disassembly and material recovery, addressing the problem at its root.

Additional Insights on Liquid Metal Electronics

Liquid metal alloys like gallium-indium are becoming increasingly popular in flexible electronics because they combine high conductivity with mechanical softness. They can stretch, deform, and bend without breaking electrical connections—a major advantage over traditional metal wires.

Researchers around the world are exploring liquid metal for applications such as:

- stretchable antennas

- soft robotic actuators

- pressure and strain sensors

- shape-memory circuits

- biomedical devices that need to conform to the human body

The UW team’s composite adds an important missing piece: recyclability. Many existing liquid-metal-based devices perform well but do not address the challenge of end-of-life material recovery. By embedding droplets inside a reprocessable vitrimer polymer, this study shows how such devices can be made more environmentally responsible.

Looking Ahead

The researchers see their composite as both a practical electronic material and a starting point for rethinking the future of device manufacturing. Its combination of flexibility, self-healing ability, easy circuit patterning, and recyclability makes it an attractive candidate for future eco-friendly electronics. While additional studies will be needed to determine long-term durability and scalability, the material represents a promising step toward reducing global electronic waste and designing electronics with sustainability in mind from the very beginning.

Conductive Liquid Metal Vitrimer Composites for Reconfigurable and Recyclable Flexible Electronics