Self-Healing Composite Can Make Airplane, Automobile and Spacecraft Components Last for Centuries

Researchers have developed a new self-healing composite material that could dramatically extend the lifespan of airplanes, automobiles, wind turbines, and even spacecraft. The material is not only tougher than today’s commonly used aerospace composites, but it can also repair itself more than 1,000 times after damage. According to the research team, this approach could push the service life of composite structures from a few decades to several centuries.

The study was carried out by researchers at North Carolina State University, with collaboration from the University of Houston, and was published in the journal Proceedings of the National Academy of Sciences (PNAS). The work focuses on solving one of the oldest and most persistent problems in composite materials: interlaminar delamination.

Why Composite Materials Fail Over Time

Fiber-reinforced polymer (FRP) composites are widely used because of their high strength-to-weight ratio. They are found in aircraft wings, turbine blades, car body panels, spacecraft structures, and wind turbine components. These materials are made by stacking layers of reinforcing fibers—such as glass fiber or carbon fiber—and binding them together with a polymer matrix, usually epoxy.

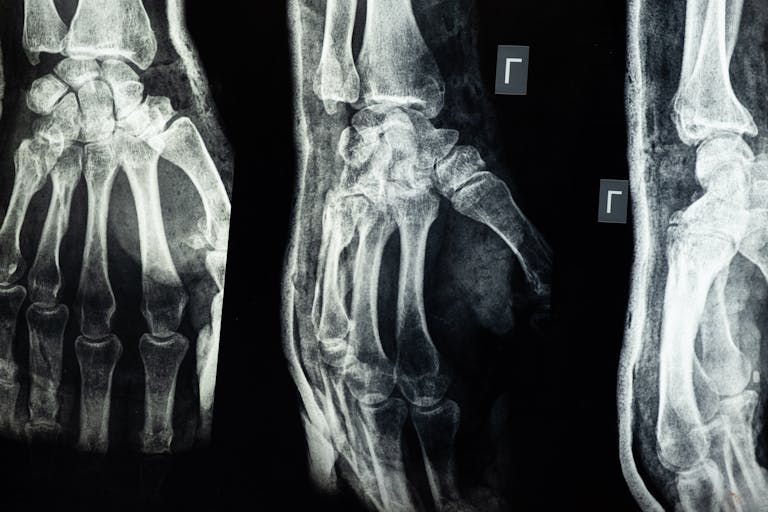

Despite their advantages, FRP composites have a well-known weakness. Over time, small cracks can form between layers, causing the fibers to separate from the surrounding polymer. This process, known as delamination, has been a challenge since the 1930s. Once delamination begins, structural strength drops, inspections become more frequent, repairs are expensive, and components often need to be replaced entirely.

Typical composite structures are designed to last 15 to 40 years, depending on usage and environment. The new self-healing strategy directly targets this failure mechanism.

How the Self-Healing Composite Is Designed

At first glance, the new material looks similar to conventional fiber-reinforced composites. However, it includes two critical additions that enable both improved toughness and repeated healing.

1. A 3D-Printed Thermoplastic Healing Agent

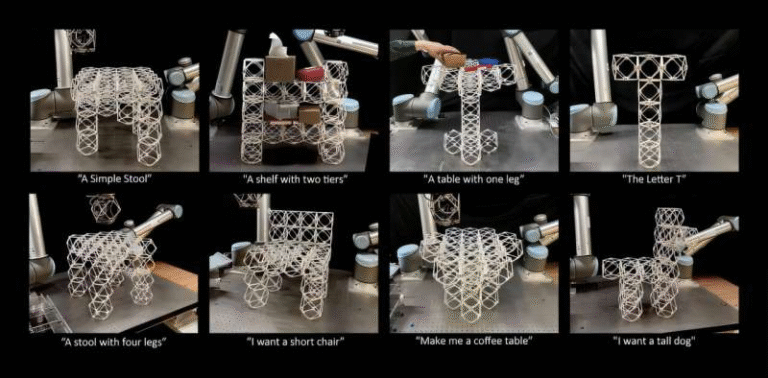

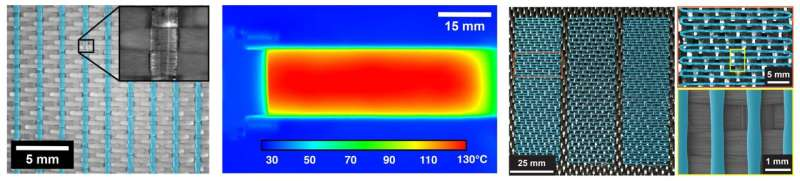

The researchers 3D-print a thermoplastic polymer directly onto the fiber reinforcement before the composite is fully assembled. This creates a patterned interlayer between the fiber sheets.

This interlayer serves two purposes. First, it makes the composite two to four times more resistant to delamination compared to standard materials. Second, it acts as a healing agent when damage occurs.

2. Embedded Carbon-Based Heating Layers

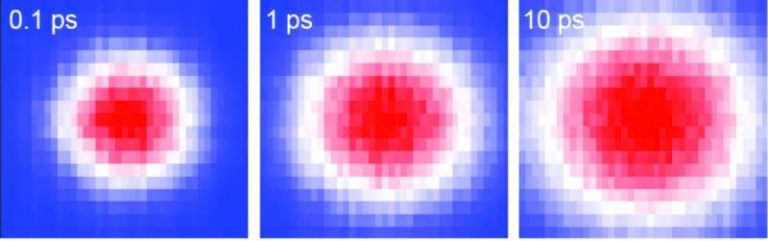

Thin carbon-based heater layers are embedded inside the composite. When an electrical current is applied, these layers heat up. The heat causes the thermoplastic healing agent to melt and flow into cracks and microfractures, rebonding separated layers and restoring structural integrity.

This process is referred to as thermal re-mending, and it allows repairs to happen in situ, without disassembling or replacing parts.

Putting the Material Through Extreme Testing

To understand how well the material performs over time, the researchers built an automated testing system designed to simulate repeated damage and repair.

In each test cycle, the system applied tensile force to create a 50-millimeter-long delamination within the composite. The heating system was then activated to heal the damage. After each repair, the team measured how much force the material could withstand before delaminating again.

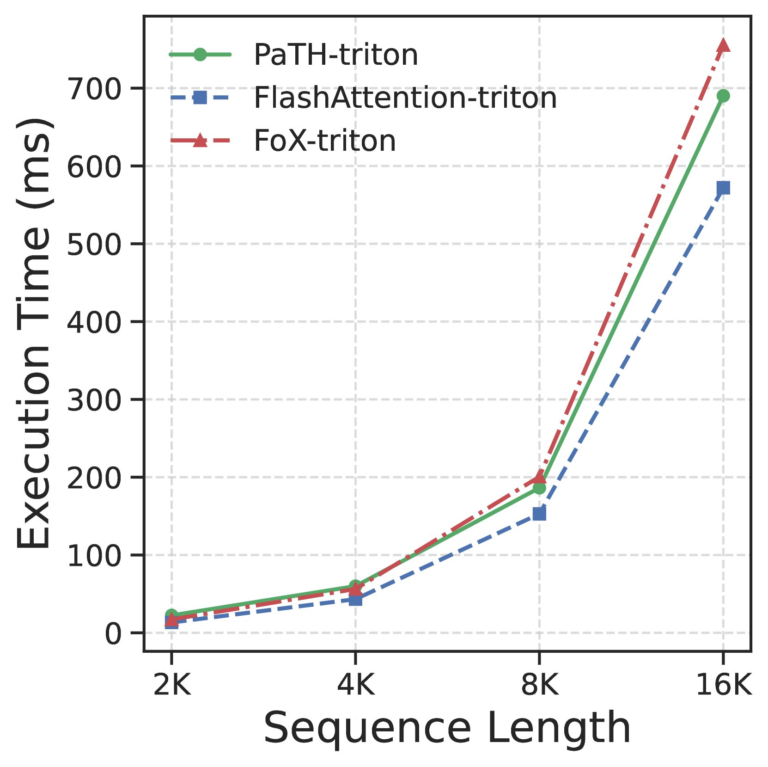

This fracture-and-heal process was repeated 1,000 times continuously over 40 days, which is an order of magnitude beyond previous self-healing composite tests.

The results showed that the material started out significantly tougher than unmodified composites. For at least the first 500 cycles, it resisted cracking better than conventional laminated composites used today. While the interlaminar toughness did slowly decline after repeated healing, the reduction happened very gradually, indicating long-term viability.

How Long Could These Materials Really Last?

The researchers modeled how this self-healing system would perform in real-world conditions, where damage would occur far less frequently than in laboratory testing.

Their estimates suggest that:

- With quarterly healing cycles, the material could last around 125 years.

- With annual healing, the lifespan could extend to 500 years.

In practice, healing would only be triggered after events such as hail impacts, bird strikes, debris damage, or during scheduled maintenance inspections.

Why Healing Performance Slowly Declines

Even though the composite can heal itself many times, the researchers wanted to understand why its performance gradually decreases.

Two main factors were identified:

- Progressive fracture of reinforcing fibers, which creates microscopic debris that interferes with rebonding.

- Chemical interactions at the interfaces between the healing agent, fibers, and polymer matrix that slowly degrade over repeated cycles.

Despite these limitations, advanced statistical modeling showed that the self-healing process remains effective over extremely long timescales. The models suggest that perpetual repair is theoretically possible, even as healing efficiency slowly diminishes.

Why This Matters for Aerospace, Energy, and Space

The implications of this technology are substantial. Composite materials are expensive to inspect, repair, and replace. Extending their lifespan could reduce maintenance costs, labor, energy consumption, and material waste across multiple industries.

For aircraft and wind turbines, fewer inspections and replacements could translate into major cost savings. For spacecraft, the impact could be even more significant. Space structures operate in environments that are largely inaccessible and often impossible to repair using conventional methods. A material that can heal itself repeatedly could fundamentally change spacecraft design and mission planning.

Commercialization and Industry Integration

The technology has already moved beyond the laboratory. The lead researcher has patented and licensed the self-healing approach through a startup company called Structeryx Inc. The system was intentionally designed to be compatible with existing composite manufacturing processes, making industrial adoption more feasible.

The research team is actively working with industry and government partners to explore real-world implementation across aerospace, energy, and transportation sectors.

A Broader Look at Self-Healing Materials

Self-healing materials have been a growing field in materials science for years. Other approaches include microcapsules filled with healing agents, vascular networks inside materials, and chemically reversible polymers. However, many of these systems are limited to one-time or low-cycle healing.

What sets this composite apart is its ability to combine structural toughness, automated heating, and repeated healing at a scale relevant for real infrastructure. This study represents one of the most convincing demonstrations yet that self-healing structural materials can function over century-long timescales.