Sound-Based Sensor Inspired by Traditional Bamboo Weaving Can Precisely Detect Helium Leaks

Helium leaks are notoriously difficult to detect, and yet they pose real risks in laboratories, industrial facilities, medical environments, and high-tech manufacturing plants. A new study published in Applied Physics Letters introduces a sound-based helium detection device that tackles this long-standing problem in an unconventional way. Instead of relying on chemical reactions like traditional gas sensors, this new system uses acoustic waves and a geometric structure inspired by traditional Japanese bamboo weaving to identify both the presence and location of helium leaks with impressive precision.

Why Helium Is So Hard to Detect

Helium presents a unique challenge when it comes to leak detection. It is odorless, colorless, tasteless, and chemically inert, which means human senses are useless, and many conventional sensors struggle as well. Most gas sensors depend on chemical interactions between the gas and a sensing material, but helium does not readily react with other substances.

Despite this, detecting helium is critical. In enclosed or poorly ventilated spaces, excess helium can displace oxygen, reducing the amount available for breathing and potentially leading to dangerous conditions. This makes reliable helium detection essential in environments such as cryogenic systems, semiconductor fabrication facilities, hospitals using MRI machines, and aerospace applications.

A Sound-Based Approach Instead of Chemistry

Researchers from Nanjing University have proposed a completely different strategy. Their device detects helium by observing how sound waves behave when the surrounding gas changes. The core idea is simple but powerful: sound travels at different speeds depending on the density and composition of the medium it moves through.

In air, sound has a predictable velocity. When helium is present, the overall gas density changes, and sound waves move differently. By carefully measuring these changes, the device can determine whether helium is present and in what concentration.

Inspiration from Traditional Bamboo Weaving

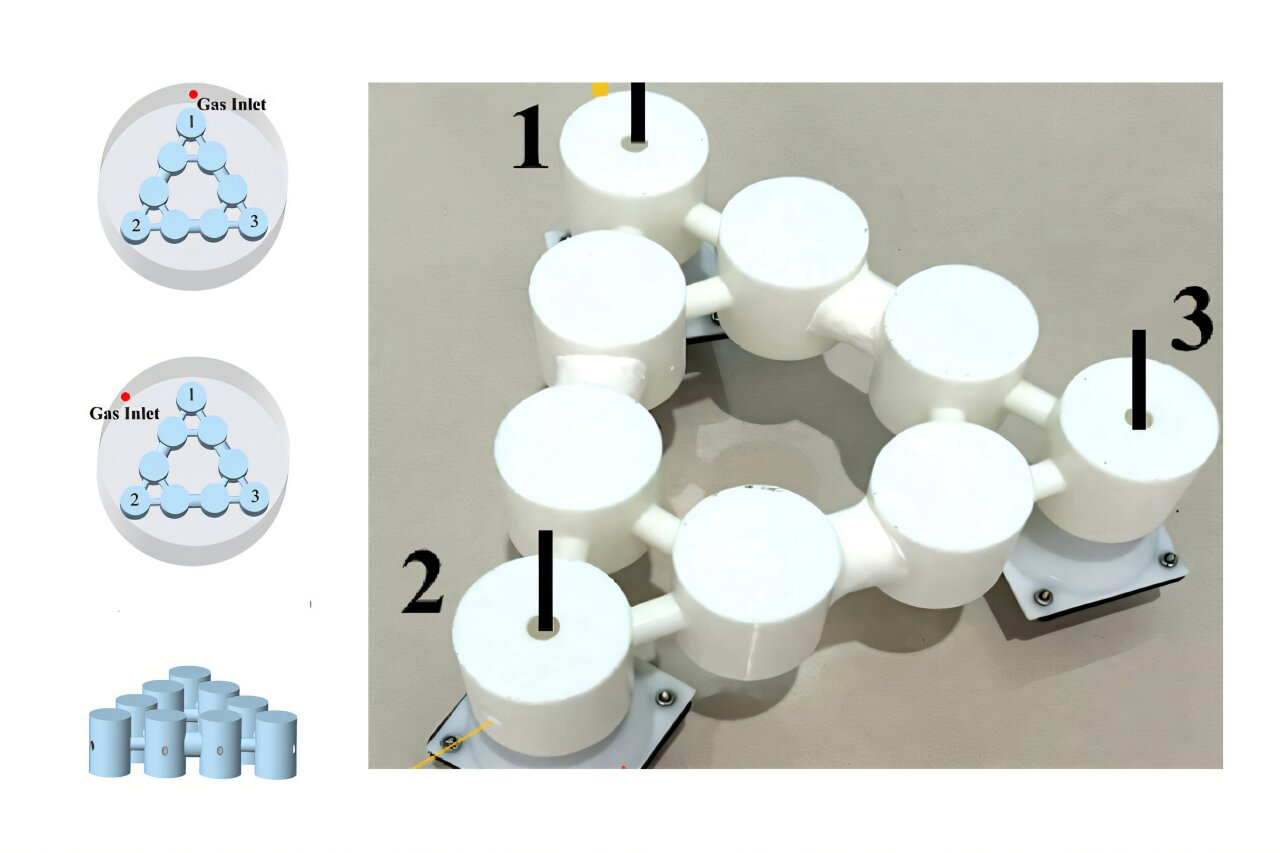

One of the most distinctive aspects of this research is the physical design of the sensor. The team drew inspiration from Kagome-biki, a traditional Japanese bamboo weaving technique known for its triangular patterns.

The resulting device features a triangular Kagome structure composed of nine hollow cylinders arranged into three smaller triangles that share their apexes. These cylinders are connected by narrow tubes that allow air or gas to circulate freely throughout the structure.

This geometry is not just decorative. It plays a crucial role in how sound waves are confined and measured within the device.

How the Device Is Built

At the corners of the triangular structure, the researchers placed microphones to capture sound signals. Beneath these corner cylinders, small speakers generate controlled sound waves. When activated, the speakers send acoustic waves into the structure, where they become localized at the corner cylinders due to the special geometry of the Kagome lattice.

Sound waves are mechanical vibrations that carry energy through a medium such as air. Their key properties include frequency, amplitude, and sound velocity. These properties determine how high-pitched a sound is, how loud it is, and how fast it travels.

Using Resonance to Detect Helium

Every physical system has a resonant frequency, which is the natural frequency at which it prefers to vibrate. When energy is applied at this frequency, the vibration amplitude increases dramatically.

Under normal air conditions, the Kagome structure resonates at specific frequencies. The microphones record stable, predictable signals when the system is operating at resonance.

When helium enters the device, the situation changes. Because helium is much lighter than air, it alters the density of the gas mixture, which in turn changes the speed of sound traveling through the structure. As a result, the sound waves no longer match the resonant frequency of the system.

This mismatch causes a sharp drop or shift in amplitude and frequency, which is immediately picked up by the microphones. By analyzing these changes, the researchers can determine the presence and concentration of helium in the surrounding environment.

Pinpointing the Location of a Leak

Beyond simply detecting helium, the device can also identify where the leak is coming from. Thanks to the triangular design, each corner acts as an independent sensing point.

When helium begins to leak into the space, the corner closest to the leak experiences changes in sound behavior first. By comparing the timing and magnitude of frequency shifts at each corner, the system can determine the direction and position of the leak in a two-dimensional space.

This spatial sensing capability is a major advantage over many traditional detectors, which can confirm the presence of a leak but offer little information about its exact location.

Performance in Extreme Conditions

One of the most promising aspects of this sound-based sensor is its stability under challenging conditions. According to the researchers, the sensor’s relative sensitivity remains constant and is largely unaffected by temperature or humidity.

This is especially important because many traditional gas sensors rely on sensitive materials that perform poorly at very low temperatures or in harsh environments. The new acoustic sensor, by contrast, can function effectively at extremely low temperatures, making it suitable for cryogenic and industrial applications where other sensors fail.

The Role of Acoustic Topological Materials

From a physics perspective, the device is described as a two-dimensional acoustic topological material. In such systems, certain sound modes, known as corner states, are highly robust. They remain stable even if the structure has minor imperfections or defects.

This topological robustness means the sensor can maintain reliable performance over time, even if the physical structure experiences slight variations during manufacturing or use. It also contributes to the device’s fast response and recovery, allowing it to quickly detect changes and return to baseline once helium levels drop.

Potential Applications Across Industries

The implications of this research are wide-ranging. Accurate helium detection is vital in industries such as semiconductor manufacturing, where helium is used in cooling and leak testing, and in medical imaging, where MRI systems rely on liquid helium. Aerospace and scientific research facilities could also benefit from more reliable and portable helium sensors.

Because the device does not rely on chemical reactions, it avoids many of the degradation issues seen in conventional sensors, potentially offering longer operational lifetimes and lower maintenance requirements.

What Comes Next for the Technology

The research team plans to take this work further by expanding the system’s capabilities. One goal is to develop a version of the device that can locate helium leaks in three-dimensional space, rather than just on a flat plane.

Another priority is miniaturization. The researchers aim to transform the current experimental setup into a portable, practical sensor that can be deployed in real-world environments without complex supporting equipment.

Why This Research Matters

This study highlights how combining fundamental physics, innovative geometry, and traditional design concepts can lead to practical technological advances. By using sound instead of chemistry, the researchers have opened up a new pathway for detecting gases that are otherwise difficult to sense.

The Kagome-inspired helium sensor demonstrates that solutions to modern engineering problems can sometimes be found by rethinking assumptions and borrowing ideas from unexpected places.

Research Reference

Applied Physics Letters (2025). “A sensor for helium leakage detection and orientation based on a two-dimensional acoustic topological material.” DOI: https://doi.org/10.1063/5.0288849