Turning Food Waste Into Jet Fuel That Meets Industry Standards

The idea of turning everyday food waste into real, ready-to-use jet fuel sounds almost too futuristic to be true. But researchers at the University of Illinois Urbana-Champaign have demonstrated that it’s not only possible—it actually works well enough to meet current aviation fuel standards without blending with fossil fuels. Their detailed study, recently published in Nature Communications, lays out how they transformed discarded food into a fuel that behaves just like conventional jet fuel used in today’s aircraft.

Below is a clear, straightforward breakdown of what the researchers did, why it matters, and how this approach fits into the wider world of sustainable aviation fuel. I’m also adding additional background sections so readers can understand the science and the industry around it.

How the Researchers Turned Food Waste Into Jet Fuel

The team focused on solving a huge issue: aviation’s contribution to greenhouse gas emissions. Air travel keeps increasing, and jet fuel—being fossil-derived—adds significantly to global and U.S. emissions. Meanwhile, more than 30% of all food produced globally is wasted, and when this waste decomposes in landfills or wastewater facilities, it emits even more greenhouse gases. So the question became: can this waste be turned into something valuable?

The answer, according to the researchers, is yes.

Their process has three clear steps:

- Hydrothermal Liquefaction (HTL)

The first stage uses a method called HTL, a high-temperature, high-pressure process that effectively mimics how the Earth naturally creates crude oil—except it happens in minutes instead of millions of years.

They fed wet food waste from a nearby processing facility into the HTL reactor. HTL is ideal for wet biomass (like food scraps, sewage sludge, algal blooms, or animal manure) because it doesn’t require drying the material beforehand. The output from HTL is a thick black biocrude oil. - Pretreating the Biocrude Oil

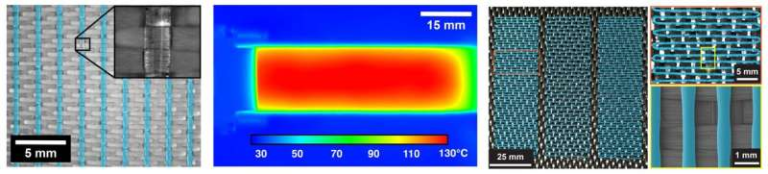

This biocrude contains impurities like moisture, ash, and salts. These must be removed before refining because they interfere with catalysts and corrode equipment. - Catalytic Hydrotreating

The treated biocrude is then processed with hydrogen and a catalyst to remove unwanted elements—especially nitrogen, oxygen, and sulfur. Removing these leaves behind mostly hydrocarbons, which are the molecules that make up jet fuel.

After testing many catalysts, the team found that cobalt molybdenum worked best. They also optimized temperature, hydrogen levels, catalyst quantity, and reaction time to get the cleanest and most fuel-like output.

Finally, they tested the resulting fuel using standards from the American Society for Testing and Materials (ASTM) and the Federal Aviation Administration (FAA). Impressively, the fuel passed Tier Alpha and Tier Beta prescreening tests and met all major jet-fuel benchmarks—again, without blending with existing fossil jet fuel.

Why This Matters for Aviation and the Environment

The aviation industry has set ambitious goals, including reaching net-zero carbon emissions by 2050. But aircraft are extremely difficult to electrify because batteries are heavy and lack energy density. Large passenger jets need fuels with very high energy per unit weight—and that’s something liquid hydrocarbons excel at.

This is where Sustainable Aviation Fuel (SAF) comes in. SAF is crucial for decarbonizing aviation because it works with existing engines and pipelines. But today’s SAF supply is extremely limited, and much of it still requires mixing with fossil fuel to meet engine requirements.

The University of Illinois team’s fuel stands out because it does not require blending or chemical additives. Many current SAFs rely on plant oils, agricultural crops, used cooking oils, or forestry residues. Adding food waste—one of the world’s largest and most problematic waste streams—to the list of viable SAF feedstocks is a significant development.

Another key advantage is that HTL can handle a huge variety of wet wastes. Besides food scraps, potential inputs include:

- Sewage sludge

- Algal blooms

- Swine manure

- Agricultural residues

This flexibility opens pathways for local production facilities that use regionally available waste streams, reducing both emissions and disposal burdens.

The Circular Bioeconomy Angle

This project is also notable for its contribution to the growing concept of the circular bioeconomy—a model where waste is continuously repurposed into new materials instead of being discarded. The lead researchers emphasize that this work fills a “missing link” in circularity. Instead of producing-consume-discard, this approach allows us to reuse the energy trapped in discarded materials.

One of the authors developed a Circularity Index to quantify how well a process recycles and reuses resources. Using this metric, converting food waste to jet fuel improves:

- Energy circularity by 31.1%

- Carbon circularity by 17.0%

It’s not perfect circularity, but it’s a measurable and meaningful improvement over traditional jet fuel, which has essentially zero circularity.

What Needs to Happen Next

Even though the results are promising, several challenges remain before this can scale up to real-world production:

- Industrial-scale testing is required. Lab success doesn’t automatically translate to cost-effective large-scale fuel production.

- Hydrogen sourcing matters. If hydrogen for hydrotreating comes from fossil fuels, the environmental benefit shrinks.

- Catalyst durability must be proven for long-term operation.

- Economic feasibility depends on local waste availability, processing costs, and policy incentives.

- Full ASTM certification (beyond prescreening) requires extensive engine and aircraft testing.

Nevertheless, the researchers believe industries can take this work and advance it toward commercial use.

Extra Background: What Exactly Is SAF?

Since this topic is getting attention worldwide, here’s a quick rundown of Sustainable Aviation Fuel beyond this particular study.

SAF refers to jet fuel made from renewable or low-carbon sources. Types include:

- HEFA (Hydroprocessed Esters and Fatty Acids) – from used cooking oil, plant oils. Currently the most common.

- Fischer-Tropsch SAF – from syngas produced by gasifying biomass or municipal solid waste.

- Alcohol-to-Jet (ATJ) – from ethanol or isobutanol.

- Power-to-Liquid or e-fuels – from captured CO₂ + green hydrogen (still expensive).

- HTL-derived SAF – like the fuel in this study.

Currently, airlines can typically use blends up to 50% SAF with conventional jet fuel. A fuel that can be used at 100% (like the one produced in this research) removes an important limitation.

Extra Background: How Hydrothermal Liquefaction Works

HTL deserves its own short explanation because it’s becoming a key technology in biofuel research.

- It uses water at extremely high temperatures (around 250–350°C) and high pressures (often over 10 MPa).

- Under these conditions, water becomes a powerful solvent that breaks down biomass.

- The output is:

- Biocrude oil

- Aqueous byproducts

- Solid char

- Gas

One of HTL’s biggest advantages is that it excels at processing wet materials, unlike many other biofuel methods that require drying, which wastes energy.

The Bottom Line

The University of Illinois team has demonstrated a practical, scientifically rigorous method to convert food waste into a drop-in jet fuel that meets key industry standards. It’s a promising contribution to sustainable aviation, waste reduction, and circular economy goals. While scaling and economic hurdles remain, the research offers a clear path forward, along with opportunities for new industries and environmental benefits.

Research Paper

From food waste to sustainable aviation fuel: cobalt molybdenum catalysis of pretreated hydrothermal liquefaction biocrude

https://www.nature.com/articles/s41467-025-64645-y